Optical fiber insulator

A technology of insulators and optical fibers, applied in the direction of insulators, optical waveguide coupling, electrical components, etc., can solve problems that hinder detection accuracy, sensor fluctuations, etc., solve high-voltage creepage problems, make significant technological progress, and improve the use of power frequency The effect of voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation, structure, features and effects provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

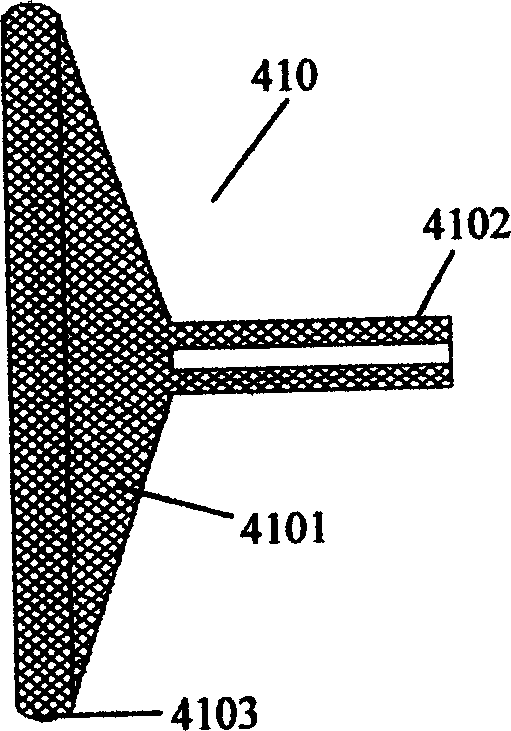

[0015] As shown in Figure 1, an optical fiber insulator includes an optical fiber insulator unit, wherein several trumpet-shaped optical fiber insulator units 410 matched in series according to the high-voltage level of the object to be tested are connected in series, and the optical fiber insulator unit has a slightly tapered disc-shaped portion 4101 The tapered surface of the disc-shaped portion of the optical fiber insulator unit can effectively prevent dust from adhering. A stem portion 4102 for wearing optical fibers extends along the top corner of the tapered surface of the disc-shaped portion. The peripheral edge of the disc-shaped portion has a convex edge 4103. In order to improve the wear resistance and insulation capacity of the optical fiber insulator; the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com