Elevator and emergency braking device for the same

An emergency braking and elevator technology, applied in the field of elevators, can solve problems such as one-end contact and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

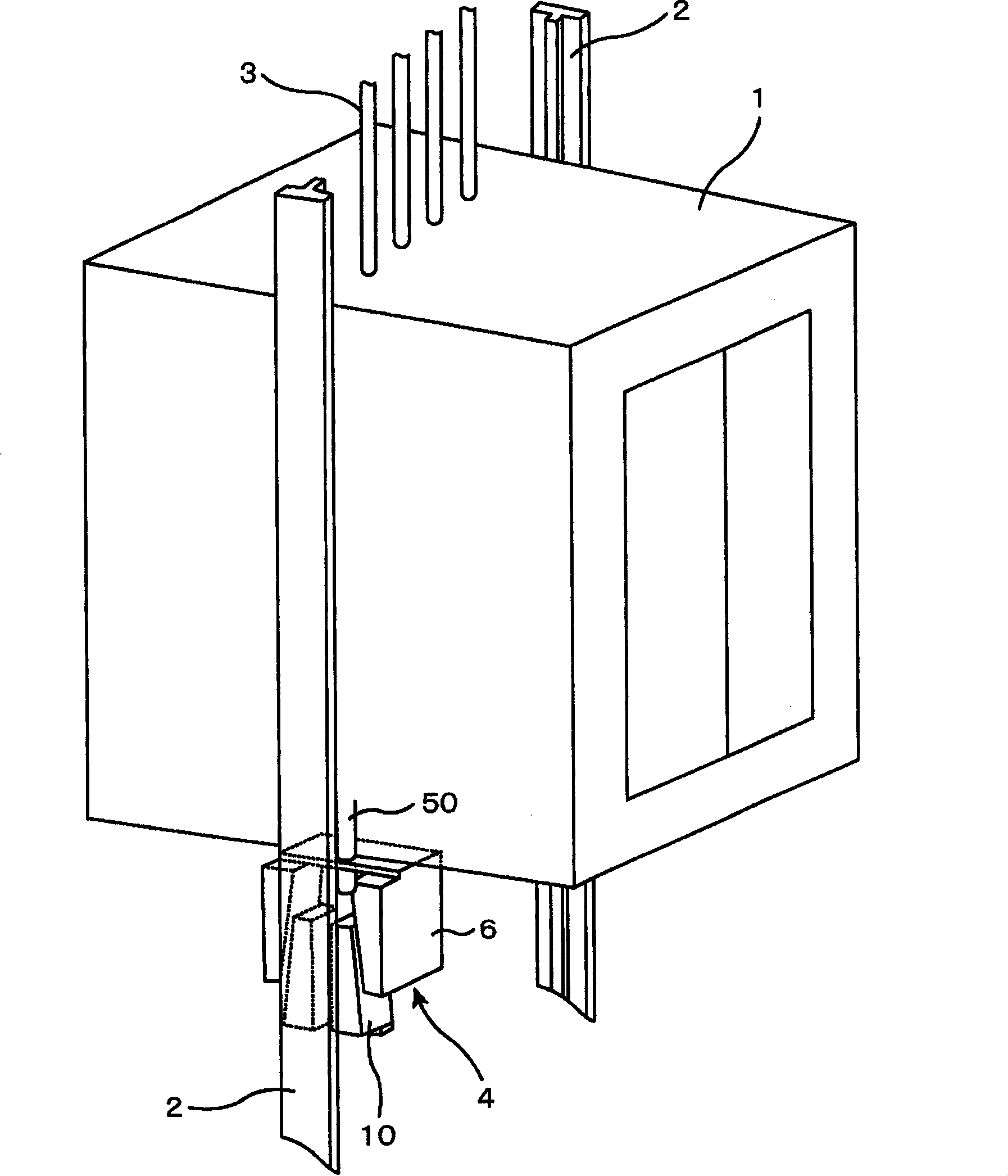

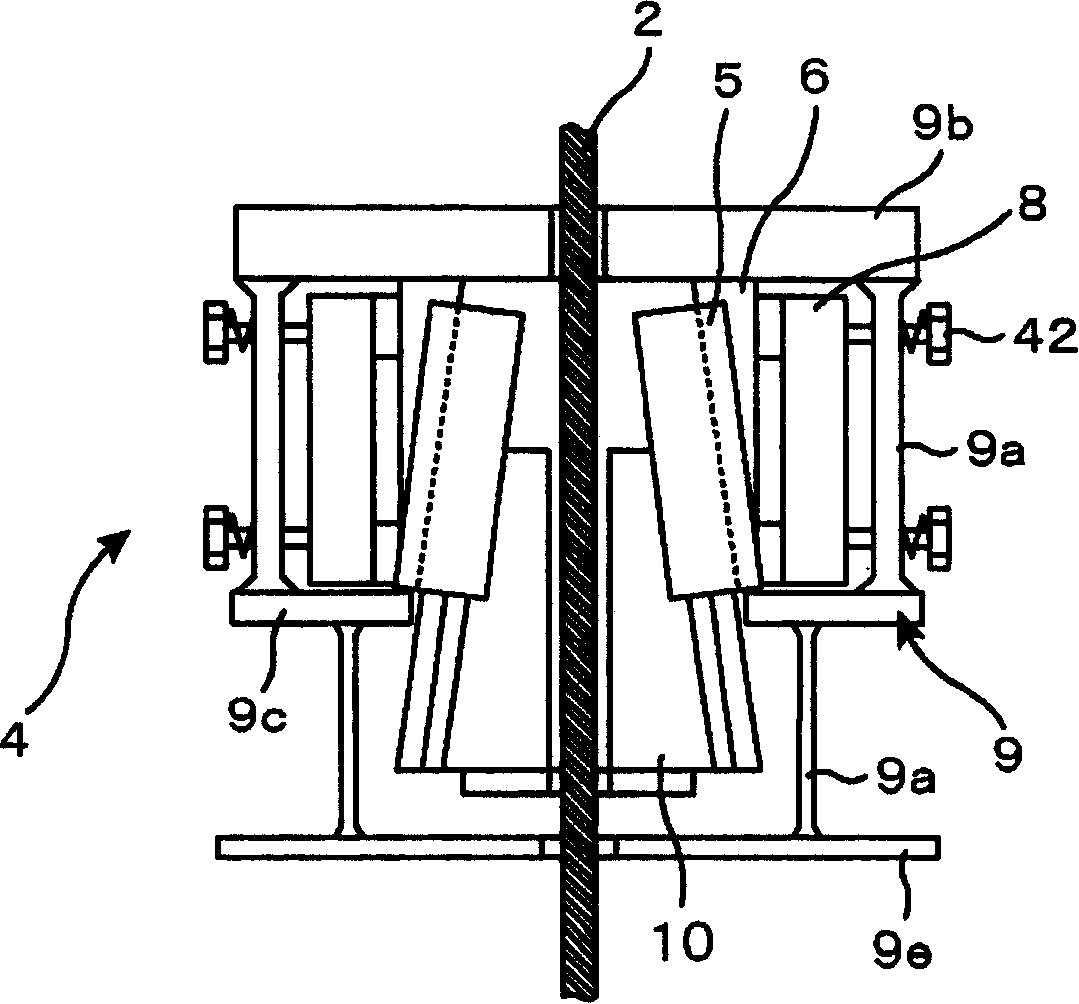

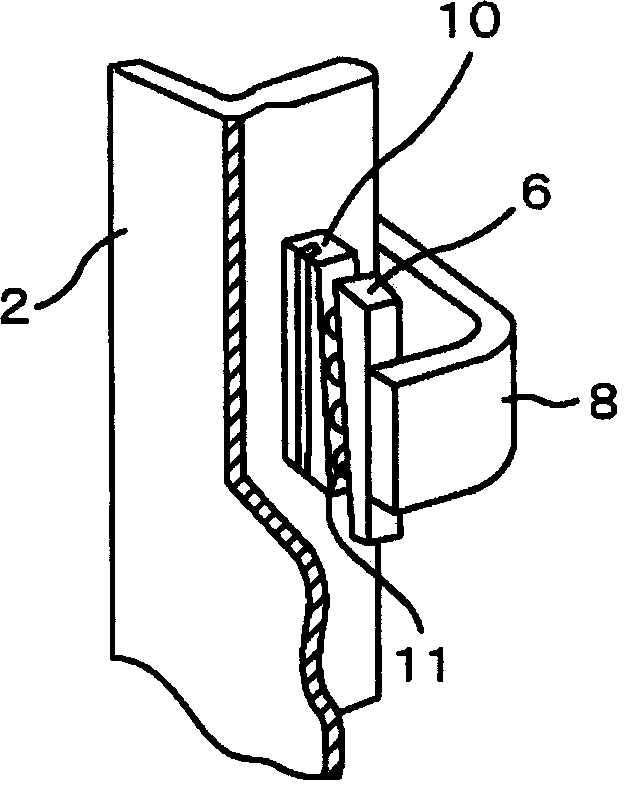

[0038] Hereinafter, an embodiment of the elevator according to the present invention and the emergency braking device used in the elevator will be described with reference to the drawings. figure 1 It is a perspective view of an elevator car 1 of the elevator and an emergency braking device installed in the lower part of the elevator car. The elevator car 1 for passengers is connected to a drive system (not shown) on the uppermost floor of the building via a sling 3. At that figure 1 In order to facilitate understanding, detailed illustrations of the elevator door opening and closing mechanism and the outer frame are omitted. On both sides of the hoistway 60, a pair of guide rails 2 and 2 are provided for guiding the elevator car 1 when it goes up and down.

[0039] A pair of emergency braking devices 4, 4 are provided at the bottom of the elevator car 1. The pair of emergency brakes sandwiches the T-shaped longitudinal rods of the guide rails 2 and 2 each having a T-shaped cros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com