Technology for improving corrugated box board paper strength using laccase treating OCC pulp

A corrugated box and laccase technology, applied in fiber raw material processing, pulp raw material addition process, paper and other directions, can solve problems such as increasing production cost and affecting the effect of adding papermaking enhancers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

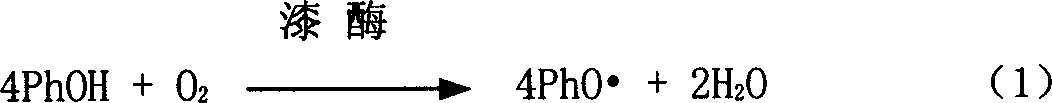

Method used

Image

Examples

specific Embodiment approach

[0054] (1) Preparation of pulp suspension

[0055] Hydropulper disintegration: Unbleached chemical pulp, semi-chemical pulp and OCC waste paper are first disintegrated in a hydropulper to prepare pulp with a certain concentration. For OCC waste paper, it is also necessary to remove heavy and bulky impurities in the waste paper during the shredding process.

[0056] Deflagging: For OCC waste paper pulp, fiber separators, disc refiners or high-frequency deflakers are used for deflaking. The purpose is to further decompose the OCC waste paper pulp into a single fiber state.

[0057] Purification and screening: For OCC waste paper pulp, use a cleaner and screener for purification and screening. Deslagging is to remove impurities in waste paper pulp by using the principle that impurities are different from fibers in specific gravity; screening is to use the principle of different shapes and sizes of impurities and fibers to remove impurities in waste paper pulp that are close to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com