Preparation method of high wet compressive strength sand binder material

A technology of binder material and wet compressive strength, which is applied in the field of preparation of high wet compressive strength molding sand binder materials, can solve the problems of limited use of binder materials, poor drying performance and wet compressive strength, and achieve Reduce moisture absorption and improve dry tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

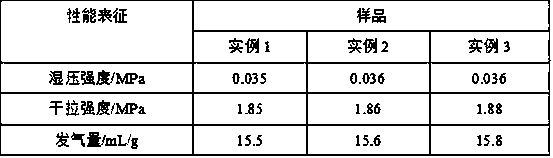

Examples

example 1

[0018] In parts by weight, weigh 45 parts of mass fraction 90% ethanol solution, 10 parts of monochloroacetic acid, 6 parts of sodium hydroxide, 10 parts of propylene oxide and 10 parts of cornstarch in a mixer, stir and mix and collect the slurry , put the slurry in a three-necked flask, stir and mix, and pass nitrogen to remove the air. Control the nitrogen flow rate to 25mL / min. Adjust the pH to 6.5 with 1% hydrochloric acid at room temperature, stir and mix, rinse with 90% absolute ethanol for 3 times, collect the emulsion, filter, and vacuum freeze-dry to obtain modified starch granules; take rapeseed meal and grind it through an 80-mesh sieve , to get the sieved particles and count by weight parts, respectively weigh 55 parts of deionized water, 15 parts of 200 mesh blast furnace slag, 25 parts of sieved particles, 10 parts of potassium permanganate, 25 parts of rapeseed oil, 6 parts of phosphoric acid Anhydride and 15 parts of modified starch granules were placed in a m...

example 2

[0020] In parts by weight, weigh 47 parts of mass fraction 90% ethanol solution, 12 parts of monochloroacetic acid, 7 parts of sodium hydroxide, 12 parts of propylene oxide and 12 parts of cornstarch in a mixer, stir and mix and collect the slurry , put the slurry in a three-necked flask, stir and mix, pass nitrogen to remove the air, control the amount of nitrogen flow to 27mL / min, after the completion of the flow, then keep the reaction at 57°C under nitrogen atmosphere for 7h, let stand and cool to Adjust the pH to 6.5 with 1% hydrochloric acid at room temperature, stir and mix, rinse with 90% absolute ethanol for 4 times, collect the emulsion, filter, and vacuum freeze-dry to obtain modified starch granules; take rapeseed meal and grind it through an 80-mesh sieve , to get the sieved particles and weigh 57 parts of deionized water, 17 parts of 200 mesh blast furnace slag, 27 parts of sieved particles, 12 parts of potassium permanganate, 27 parts of rapeseed oil, and 7 parts...

example 3

[0022] In parts by weight, weigh 50 parts of 90% ethanol solution by mass fraction, 15 parts of monochloroacetic acid, 8 parts of sodium hydroxide, 15 parts of propylene oxide and 15 parts of cornstarch in a mixer, stir and mix and collect the slurry , put the slurry in a three-necked flask, stir and mix, and ventilate the air with nitrogen. Adjust the pH to 6.5 with 1% hydrochloric acid at room temperature, stir and mix, rinse with 90% absolute ethanol for 5 times, collect the emulsion, filter, and vacuum freeze-dry to obtain modified starch granules; take rapeseed meal and grind it through an 80-mesh sieve , to get sieved particles and by weight parts, weigh 60 parts of deionized water, 20 parts of 200 mesh blast furnace slag, 30 parts of sieved particles, 15 parts of potassium permanganate, 30 parts of rapeseed oil, 8 parts of phosphoric acid Anhydride and 20 parts of modified starch granules were placed in a mixer, stirred and mixed at 60 for 30 minutes, allowed to stand a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com