Process and apparatus for drying a fibrous product mass flow

A technology of fiber products and mass flow, which is applied in the directions of tobacco drying, drying solid materials, and dry cargo handling, etc., and can solve problems such as inertial damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

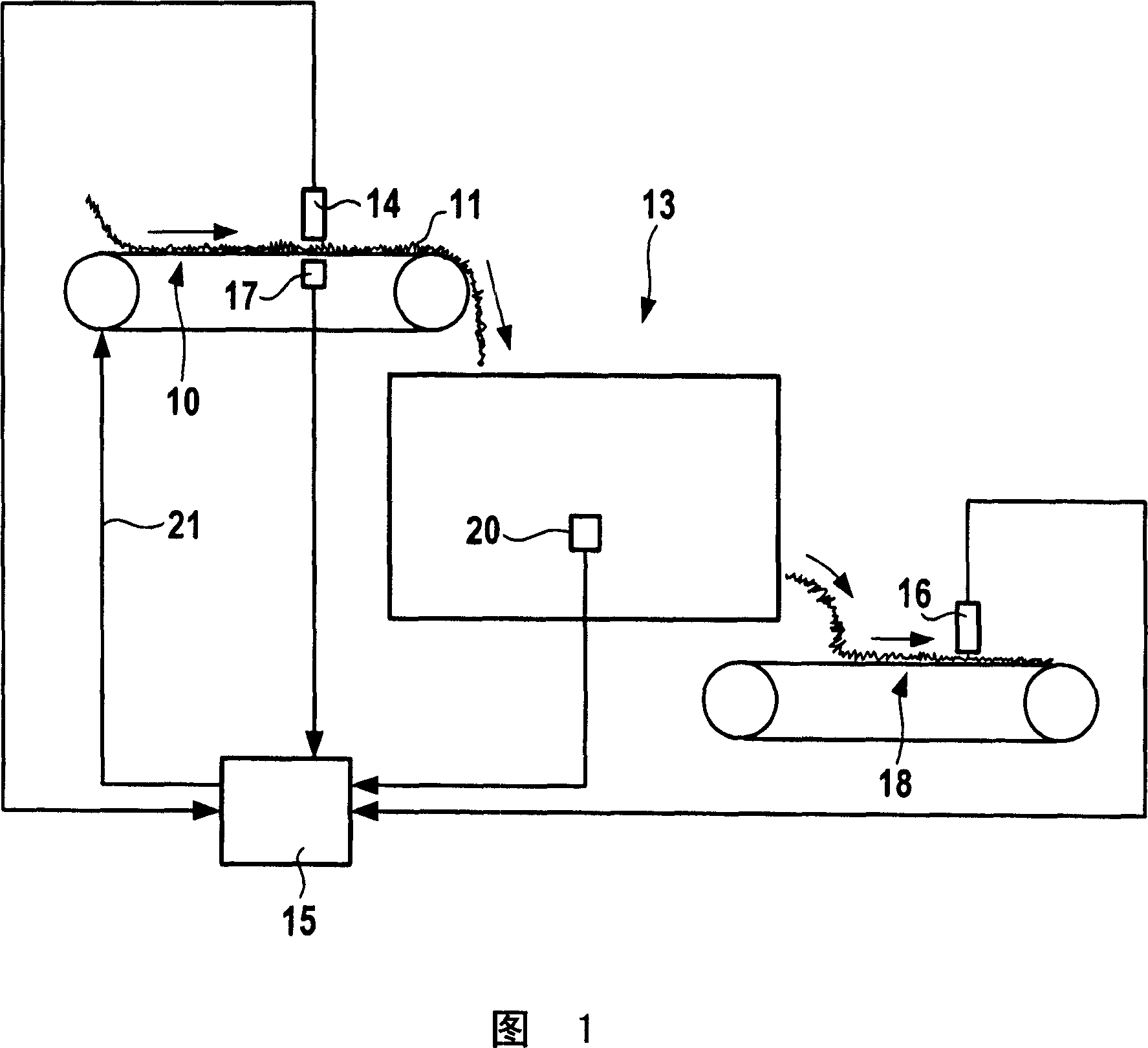

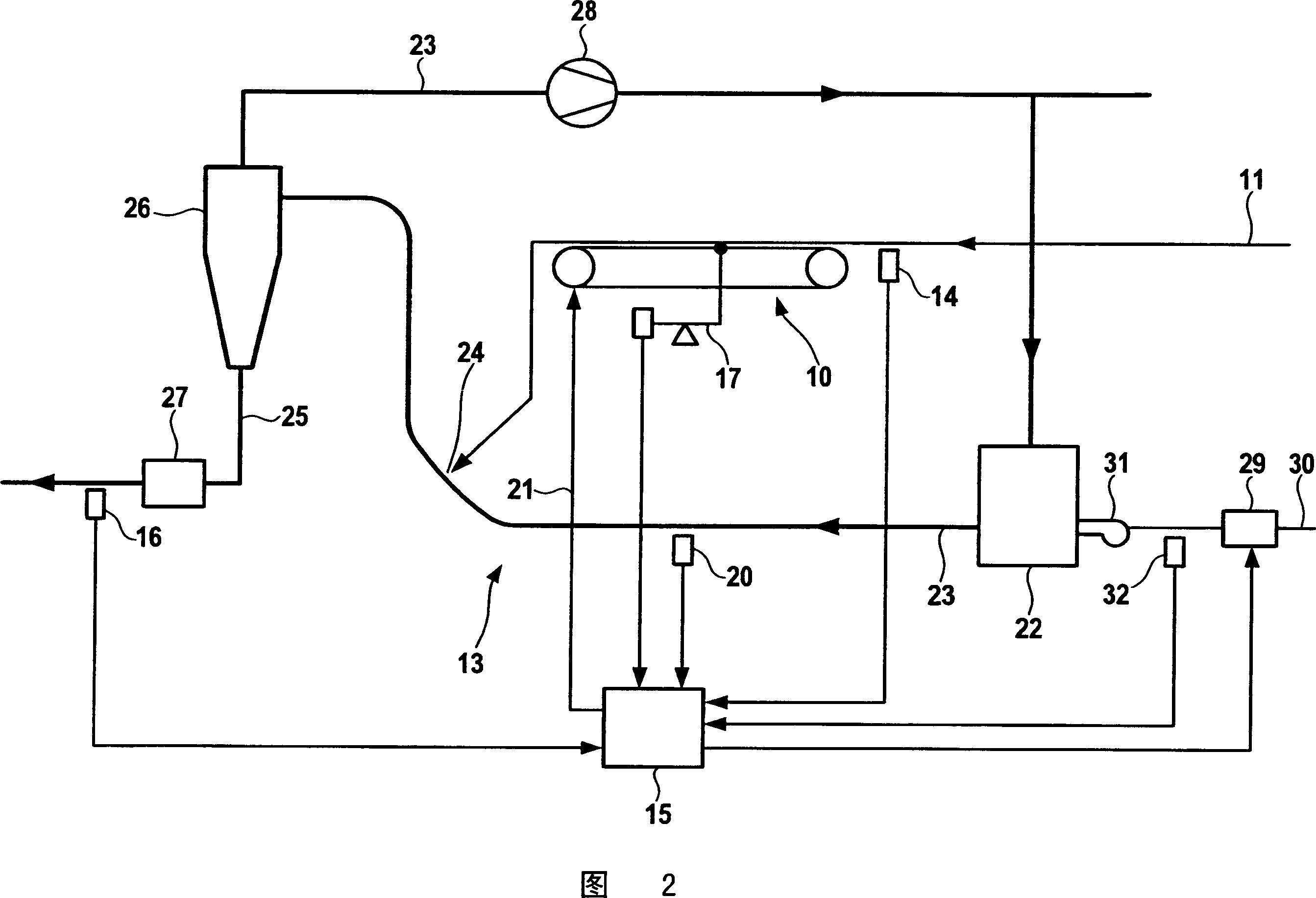

[0014] Tobacco products 11 to be dried are conveyed to the dryer 13 in the direction of the arrow by conveying means 10, which in this embodiment is, for example, a conveyor belt. In the dryer 13 , heating means (not shown in FIG. 1 ) cause heating of the tobacco products 11 guided through the dryer 13 in order to dry them by evaporating the moisture contained in the products 11 . For example, the dryer 13 may be a flash dryer, a tumble dryer, a turbulent bed dryer or some other dryer known to the expert. After the dried products leave the dryer 13, they are transported away by another conveying device 18, which is also a conveyor belt in this embodiment.

[0015] A sensor 20 suitably installed in the dryer 13 is provided to measure a quantity that is clearly related to the drying temperature. In particular, the sensor 20 may be a temperature sensor for measuring the drying temperature. A corresponding measurement signal of the drying temperature is transmitted to the contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com