Light source configuration method for online detecting system of stip cigarette packing quality

A detection system and configuration method technology, applied in the direction of optical testing flaws/defects, etc., can solve problems such as difficult identification and processing, high difficulty in realization, and reflection of oil seal paper, so as to achieve the effect of eliminating reflection, convenient identification and processing, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

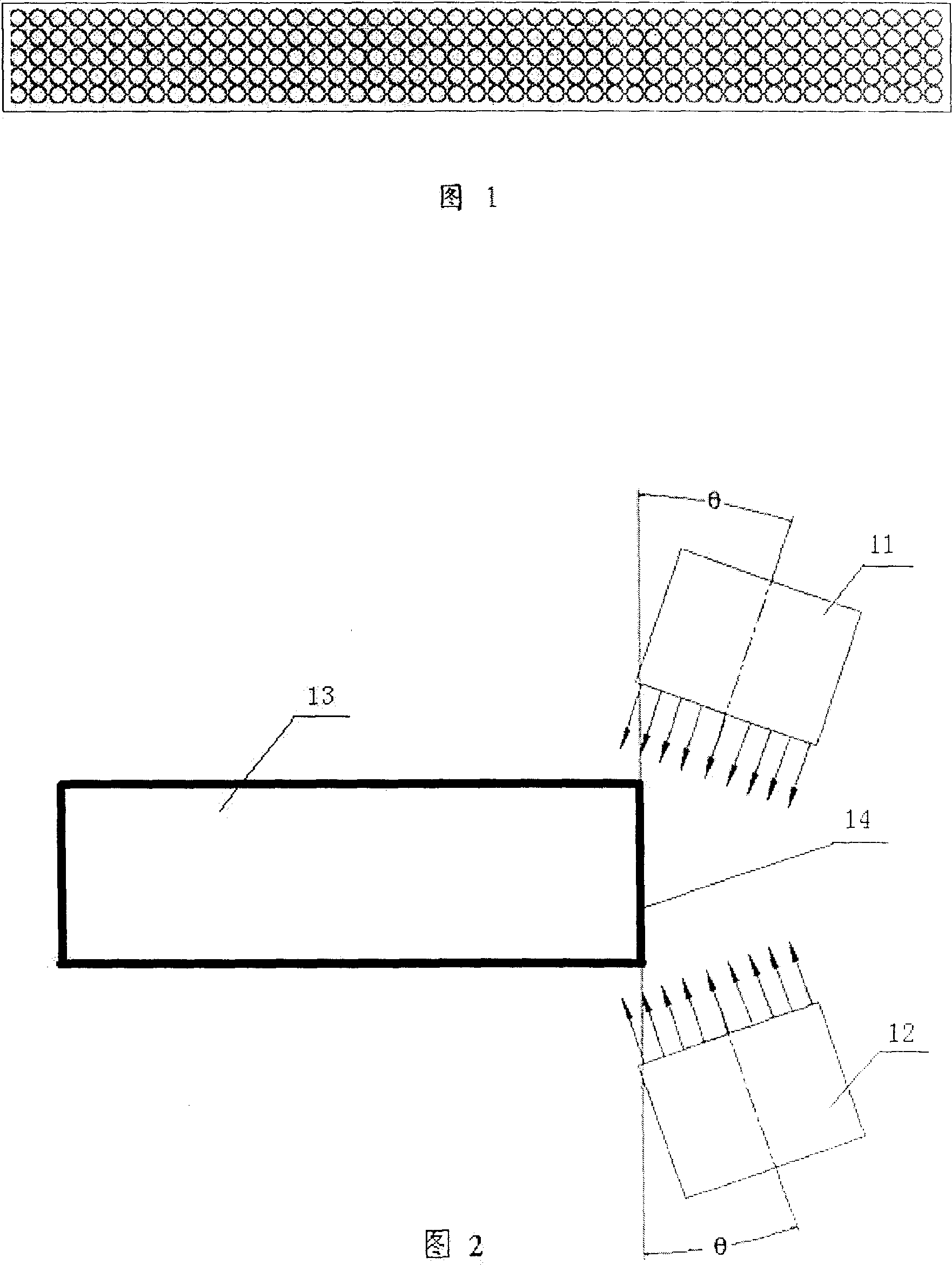

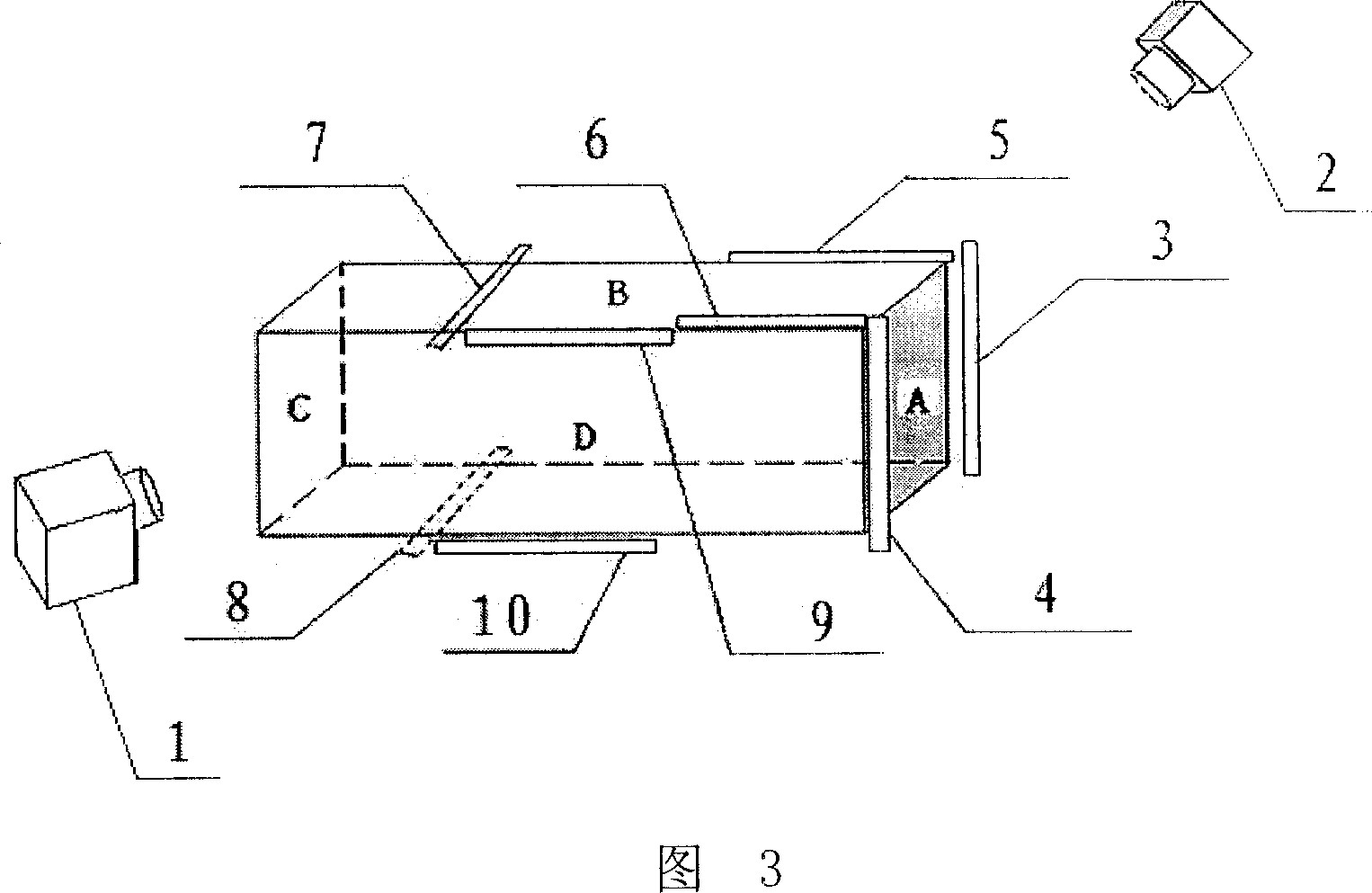

[0014] As shown in Figure 1, the present invention uses high-brightness LED strip light as the lighting source, and the LED light source is composed of LED particles of the same color or different colors arranged regularly, and the lighting method is shown in Figure 2, using low-angle parallel light, that is The included angle θ between the light emitted by the light sources 11 and 12 and the irradiated surface 14 of the cigarette 13 is less than 15°. Monochromatic light source or mixed color light source can be used. Monochromatic light source means that all LED particles in one light source are of the same color and size. Such LED light source emits light evenly, which can meet the requirement of emitting parallel light and is low-angle Parallel lighting provides the prerequisites. Mixed color light source refers to the LED light source in a certain row or several rows and a certain column or several columns of different colors of LED combination or interphase composition, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com