Compensating method for writing power of optic disc driver

A technology of optical disc drive and compensation method, which is applied in the direction of optical recording/reproduction, optical recording/reproduction/erasing method, instrument, etc., can solve the problems of cost and volume increase, and achieve the effect of good writing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

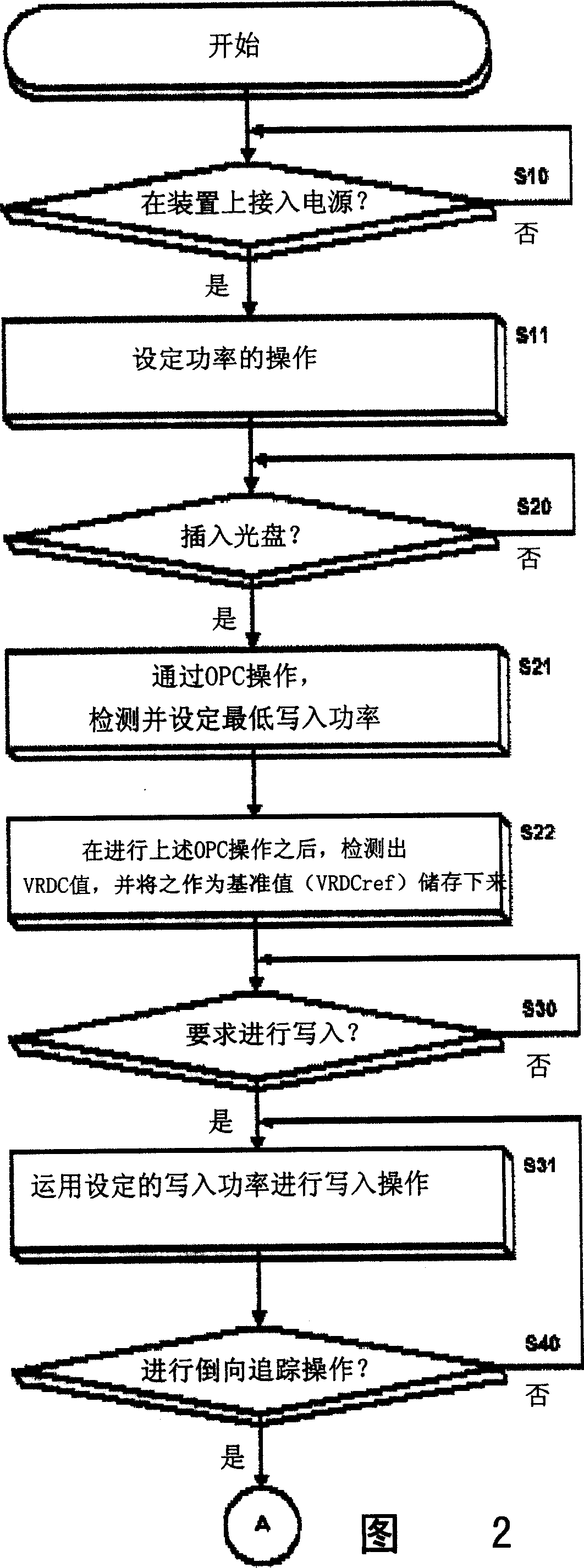

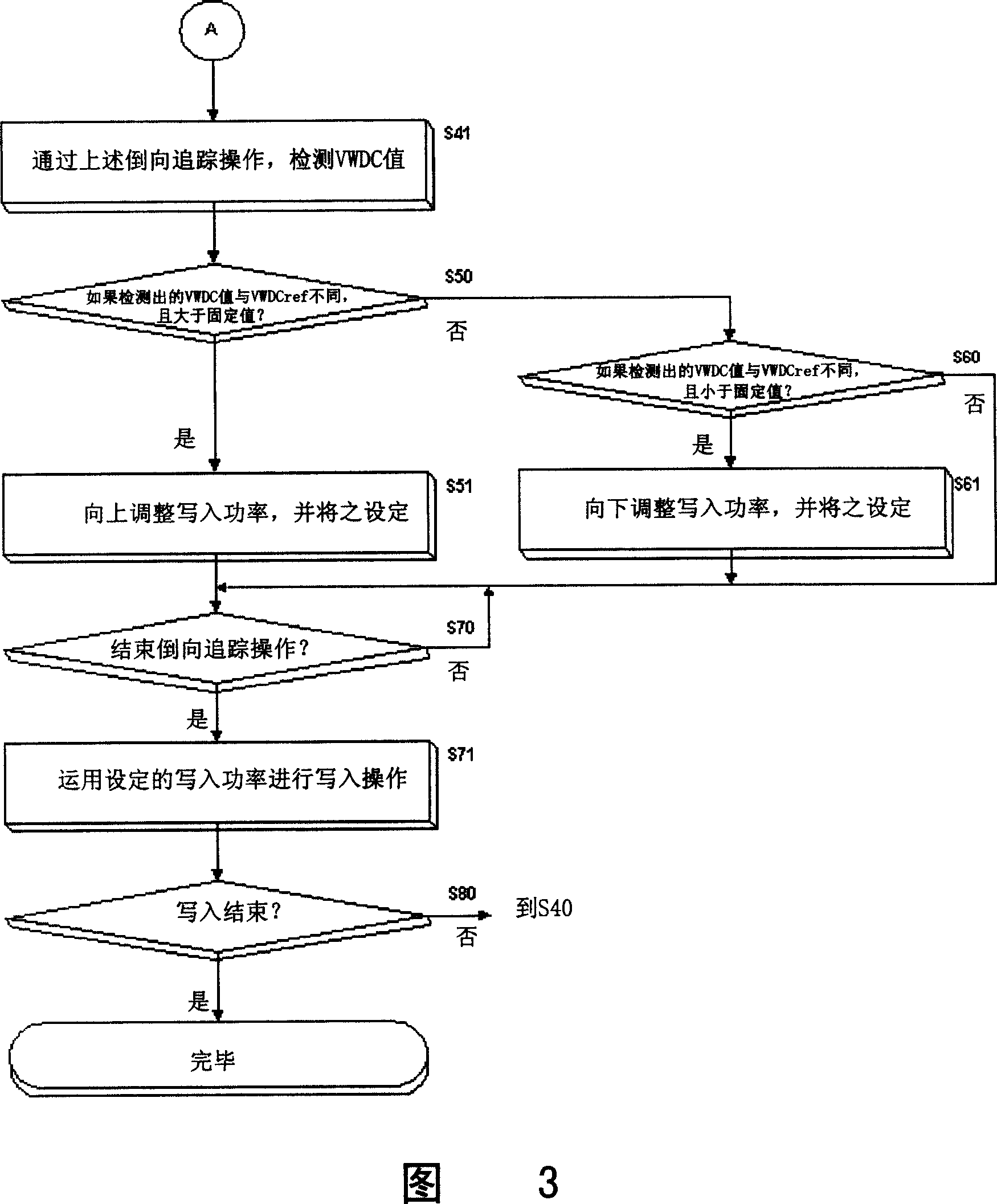

[0019] Embodiments of the method for compensating writing power of an optical disc drive according to the present invention will be described in detail below with reference to the accompanying drawings.

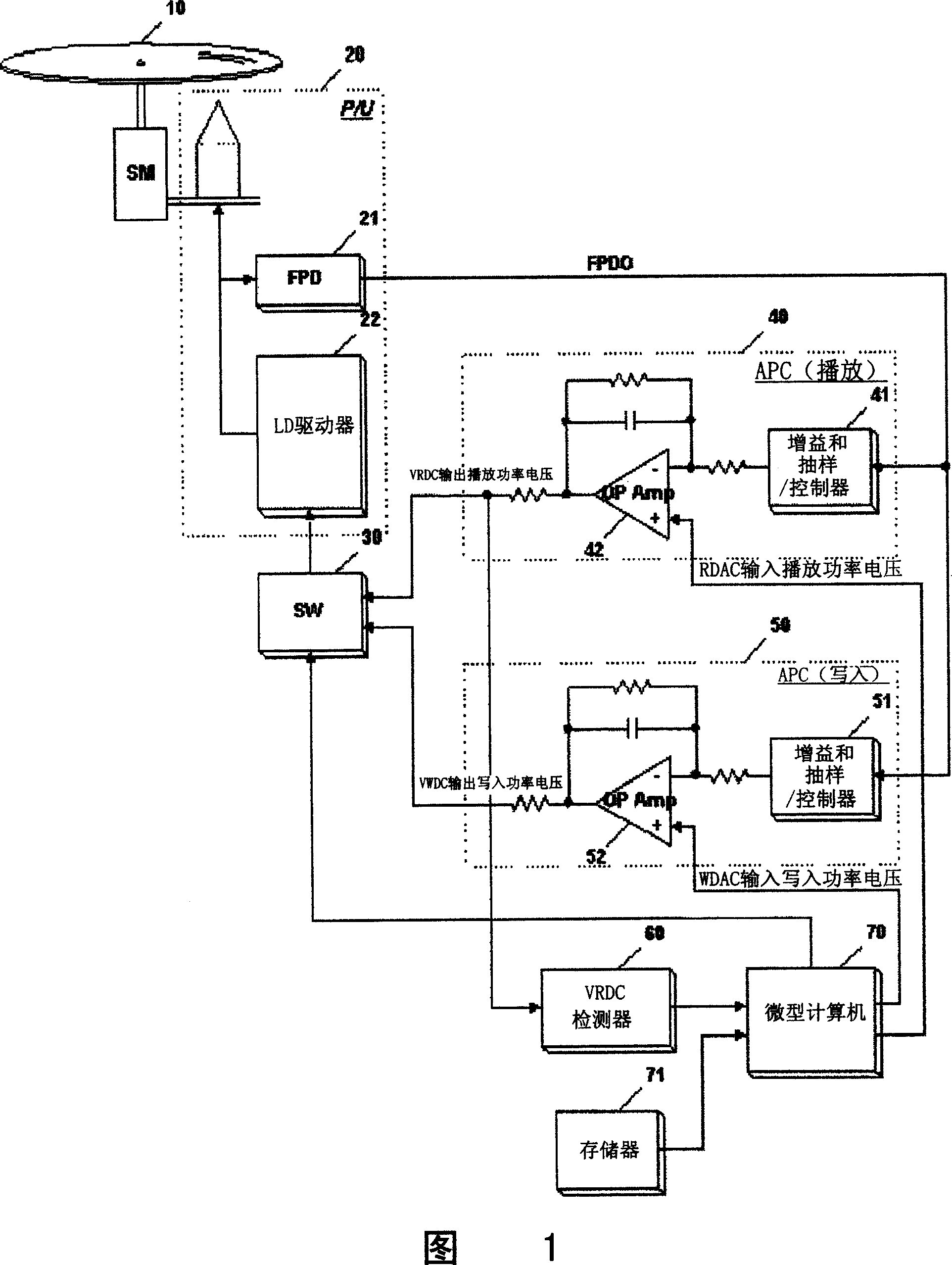

[0020] FIG. 1 is a schematic diagram showing the composition of an optical train of an optical disc drive according to a writing power compensation method of an optical disc drive of the present invention. It is composed of the following parts: it is composed of gain and sampling / controller 41 and OP amplifier 42, and plays the automatic power control (APC) of outputting the playing power voltage (VRDC) according to the input FPDO signal and the input playing power voltage (RDAC). ) circuit 40; composed of gain and sampling / controller 51 and OP amplifier 52, write automatic power control (APC) according to input FPDO signal and input write power voltage (WDAC) output write power voltage (VWDC) Circuit 50; Output the LD driver 22 of the light beam corresponding to the playback...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com