Vibration motor

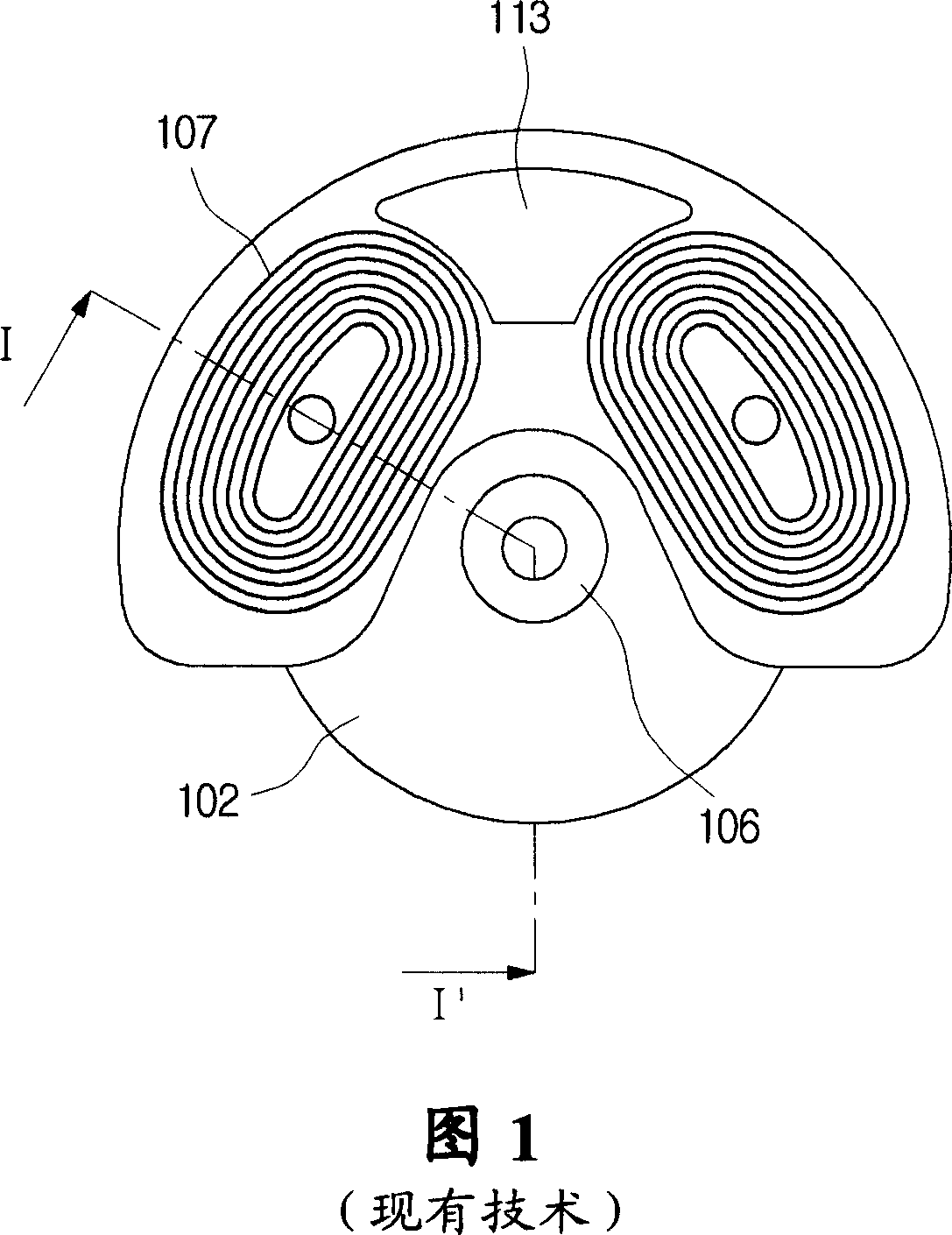

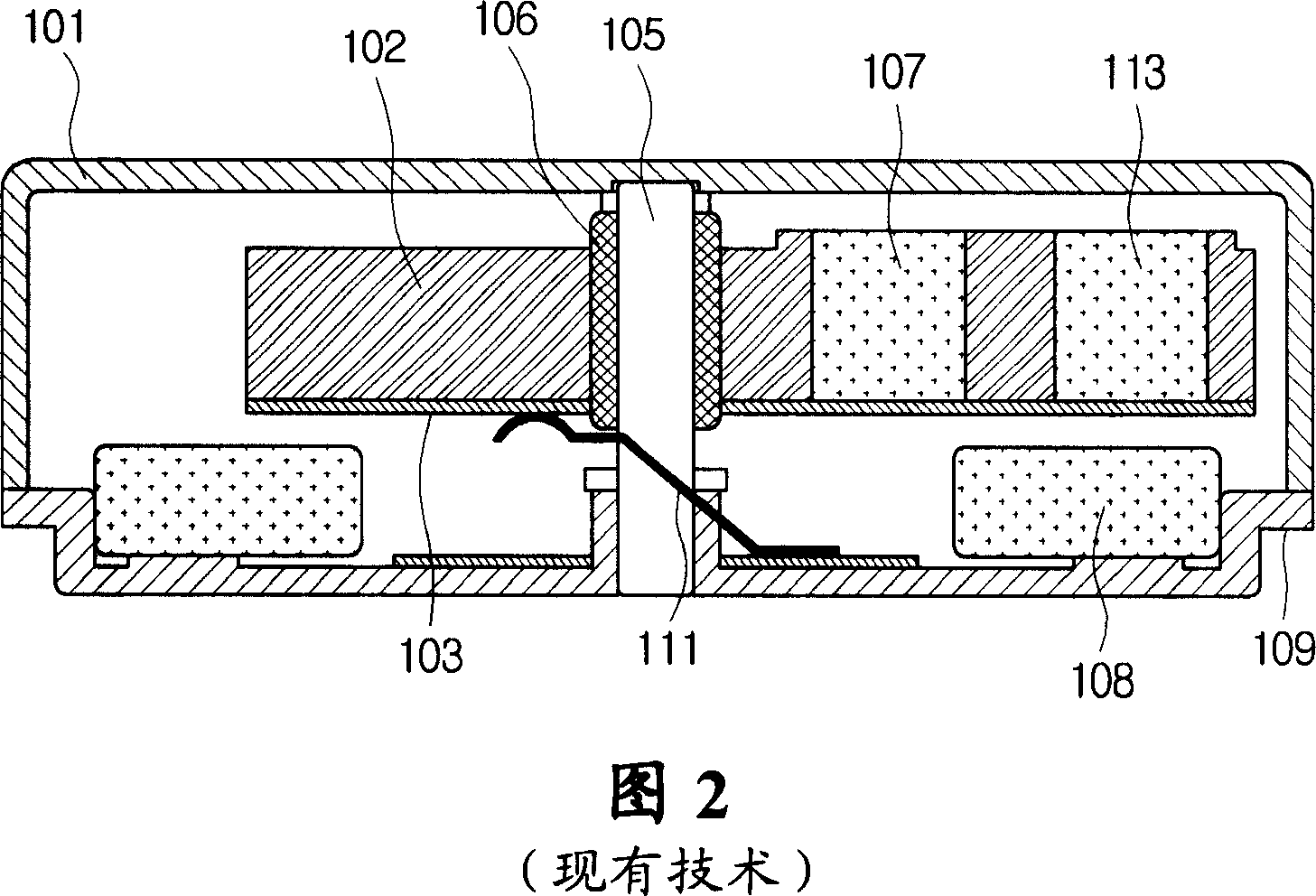

A technology for vibrating motors and bases, which is applied in the manufacture of motor generators, fluids and electrical components using vibration, etc., can solve the problems of insufficient number of magnetic lines of force, intensified motor vibration, and inability to increase the size of coil 107.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

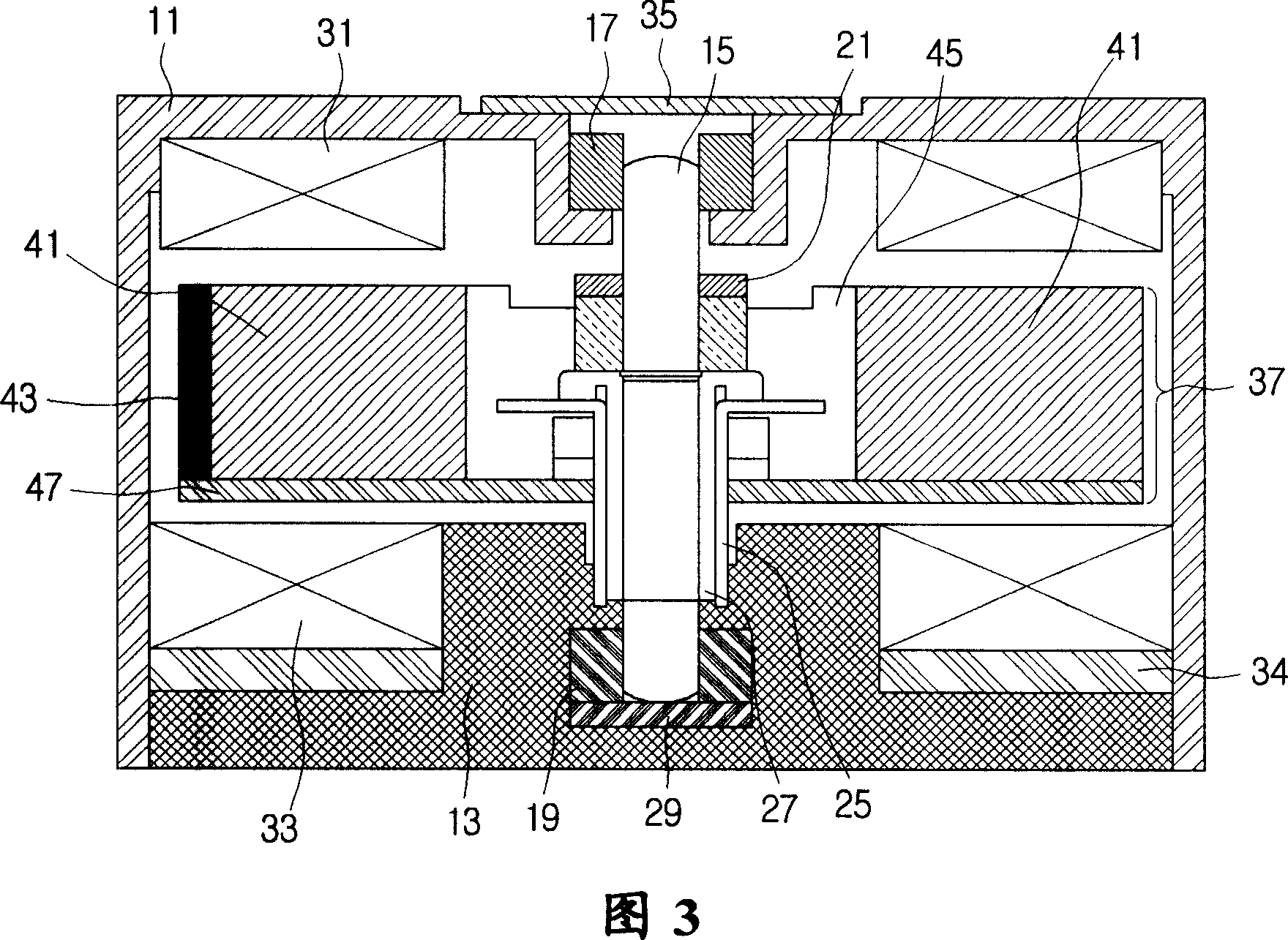

[0021] Hereinafter, embodiments of the present invention will be described more specifically with reference to the accompanying drawings. In the description with reference to the drawings, those same or corresponding components are provided with the same reference numerals regardless of the drawing numerals, and redundant explanations are omitted.

[0022] With reference to Fig. 3, the vibrating motor according to the embodiment of the present invention comprises: base 13 and housing 11, and it forms inner space; Shaft 15, is rotatably inserted in base 13 and housing 11; support and cause vibration; the counterweight 43 is installed along the periphery of the rotor 37; the brush 25 is in contact with the commutator 27 and is positioned on the base 13; and the upper magnet 31 and the lower magnet 33 face the rotor 37 and are respectively fixed to the housing 11 and the base 13. The rotor 37 includes a wound coil 41 and a counterweight 43 which may be fixed to a hard board 47 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com