Winding compressing mechanism for stirrups in reinforcement cages in modern prefabricated construction engineering

A technology of construction engineering and compression mechanism, which is applied in the field of winding and compression mechanism of steel cage and stirrup in modern prefabricated construction engineering, can solve the problems of low efficiency, time-consuming and labor-intensive, high labor intensity, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

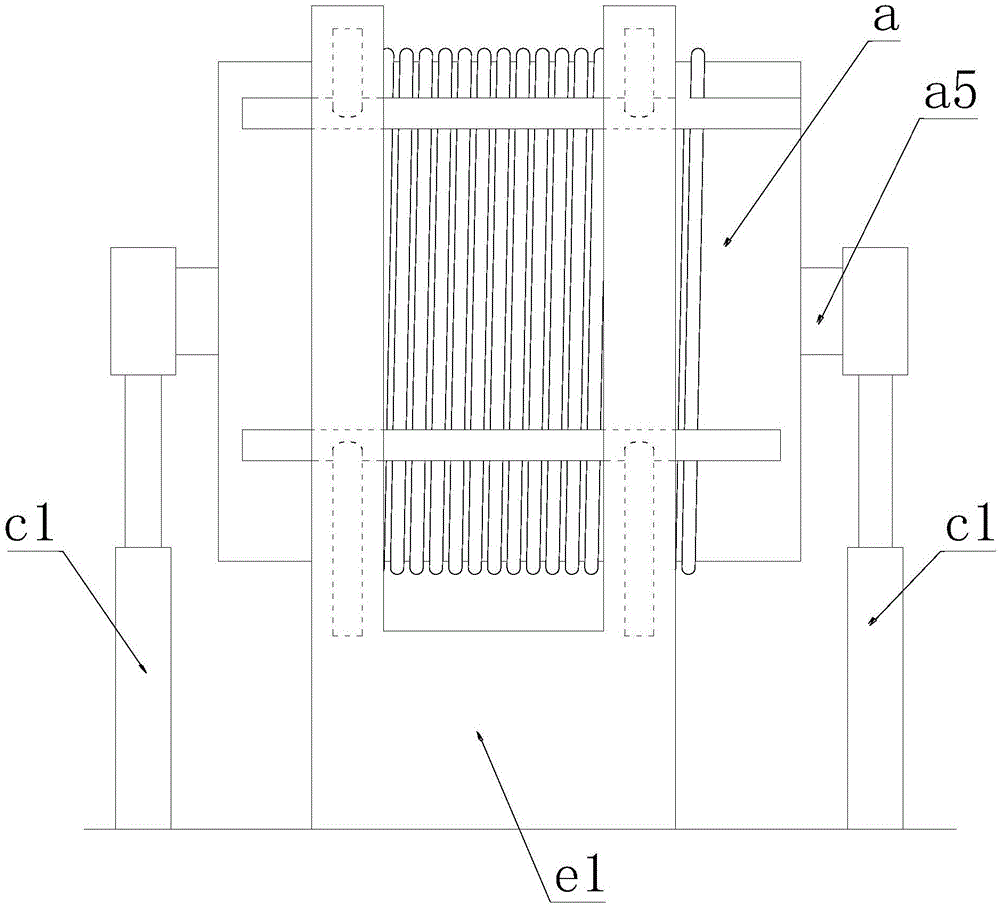

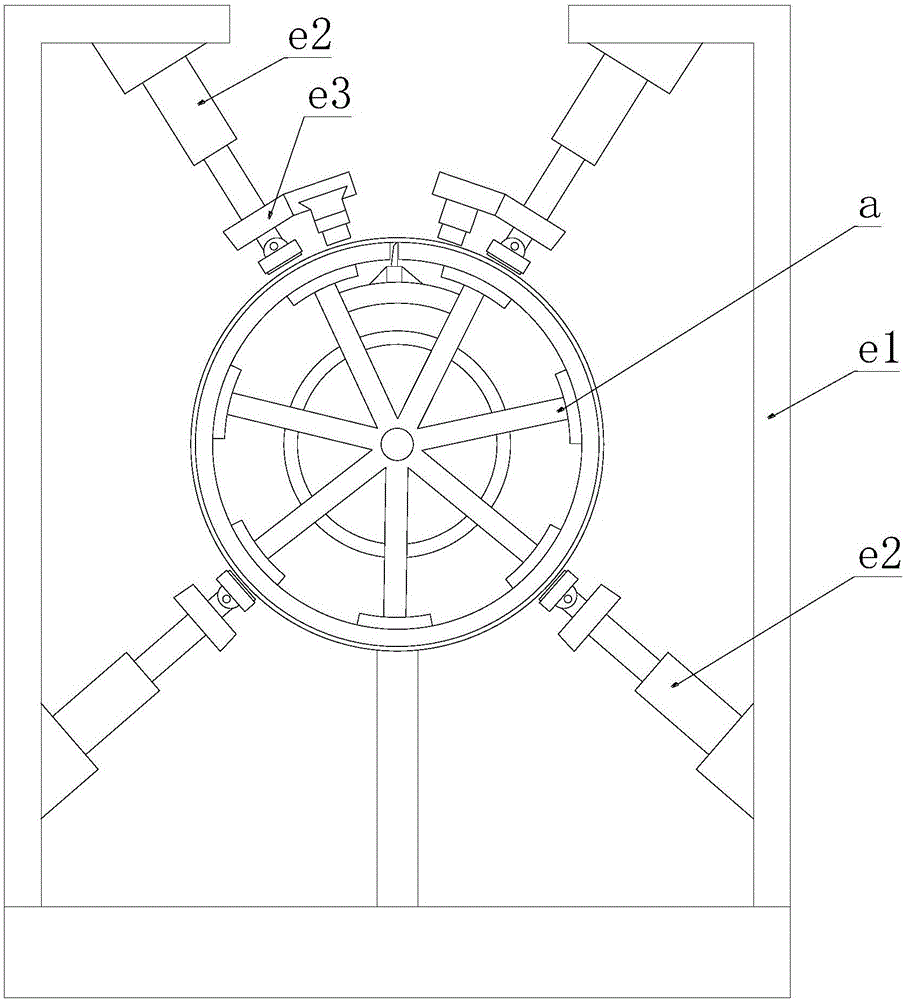

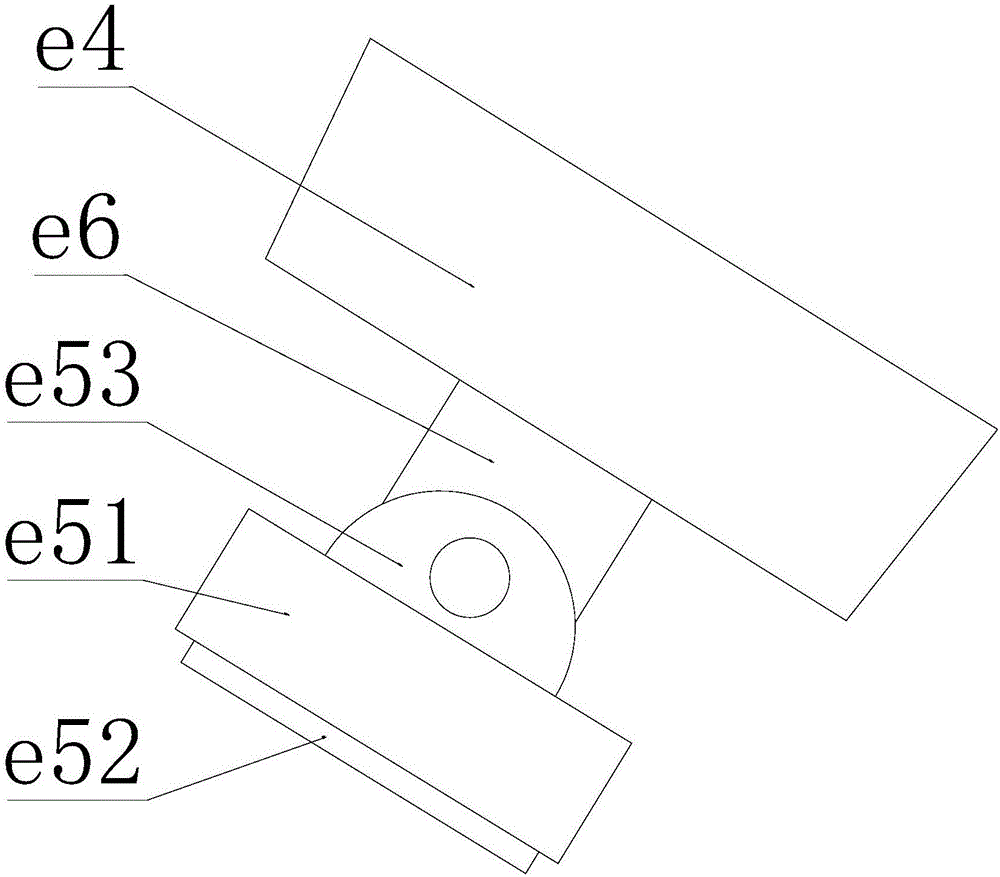

[0030] Such as Figure 1 to Figure 6 As shown, a modern prefabricated building engineering reinforcement cage stirrup coiling and pressing mechanism includes a base on which two coiling supports c1 are arranged opposite to each other, and one of the two coiling supports c1 A bobbin assembly a is installed between them, the bobbin assembly a includes a bobbin a1, the bobbin a5 is pierced inside the bobbin a1, the two ends of the bobbin a5 are respectively connected to the two winding branches The seat c1 is connected, and the bases on both sides of the cylinder a1 are respectively provided with lateral supports e1, and at least one set of pressing parts are provided on the lateral supports e1.

[0031] The cylinder wall of the cylinder a1 is provided with a strip-shaped cutout a2, the length direction of the strip-shaped cutout a2 is parallel to the cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com