Key of magnetic lock and process for preparing same

A production process and magnetic lock technology, applied in the field of locks, can solve the problems of unsightly appearance of keys, unstable product size, inconvenient mass production, etc., and achieve the effect of stable size, low cost and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

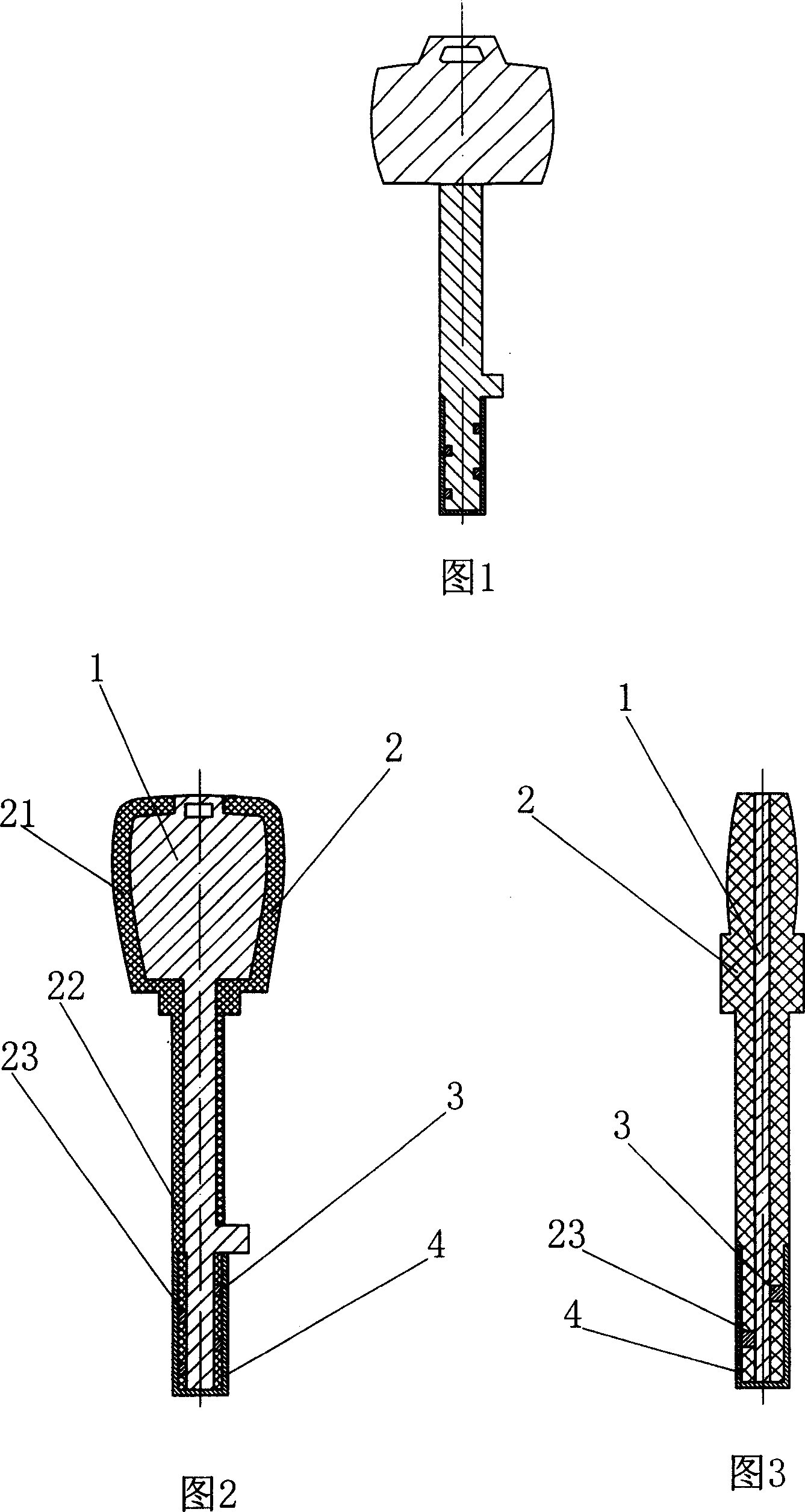

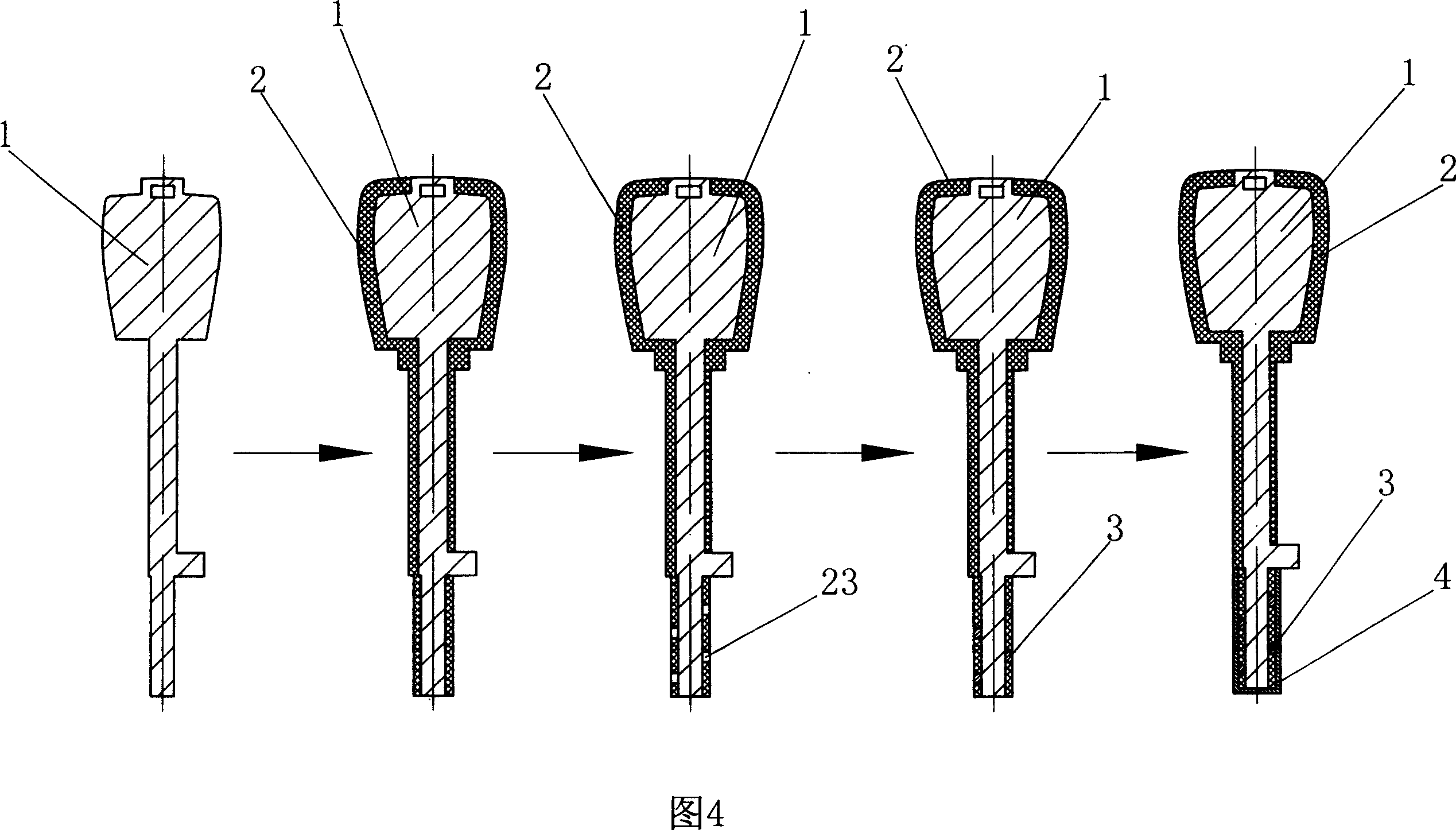

[0013] As shown in Figures 2 and 3, the specific embodiment of the present invention is a key for a magnetic lock, which is composed of a flat iron blank 1 and a plastic shell 2 wrapped outside the iron blank 1. The shape of the blank is wide at the top and narrow at the bottom, the upper part is rectangular, and the lower part is thin rod-shaped. As a reinforcement of the key, the plastic shell 2 forms the insertion part 21 and the grip part 22 of the key. The ring forms a plurality of magnetic bullet holes 23 for accommodating the magnetic bullets 3, and the front end of the insertion part 22 is covered with a magnetically conductive copper jacket 4. The axial length of the copper jacket 4 is greater than that of the uppermost magnetic bullet hole 23 on the insertion part 22. The distance from the front end of the portion 22 can just in time all the magnetic bullet holes 23 be closed, because the purpose of the copper overcoat 4 is to protect the magnetic bullet 3.

[0014] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com