Electric kettle

A technology for electric kettles and spouts, which is applied in pouring spouts, water boiling utensils, and kitchen utensils. The structure of the pot body is simple, and the effect of reducing the noise of boiling water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

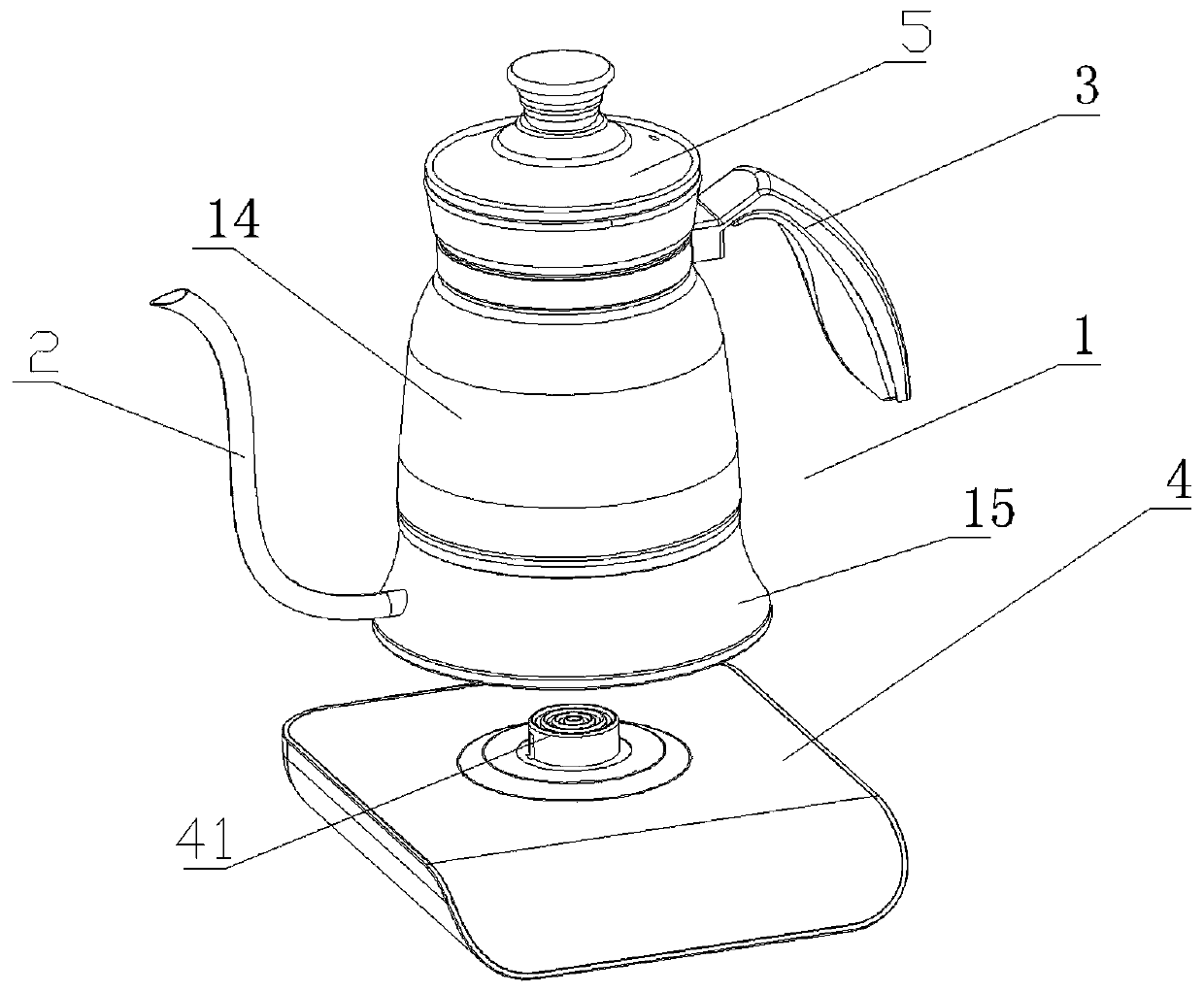

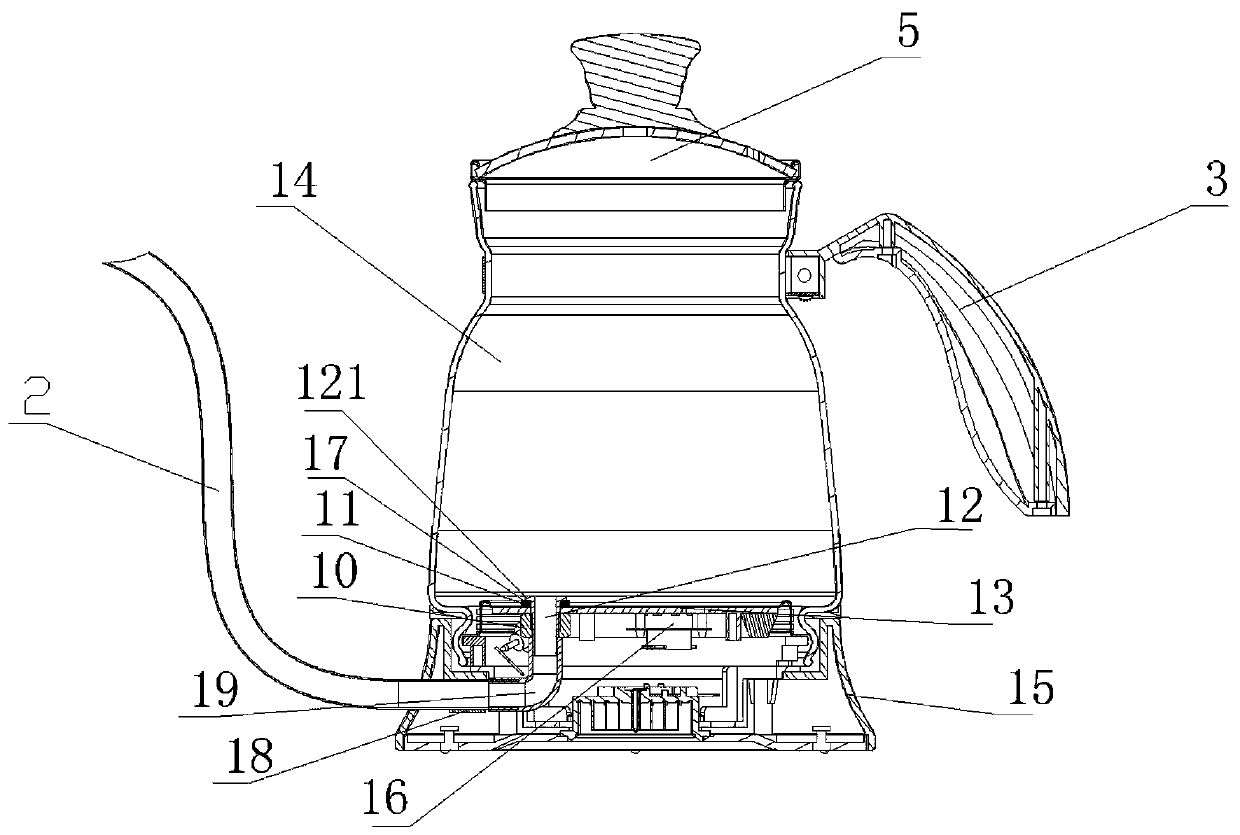

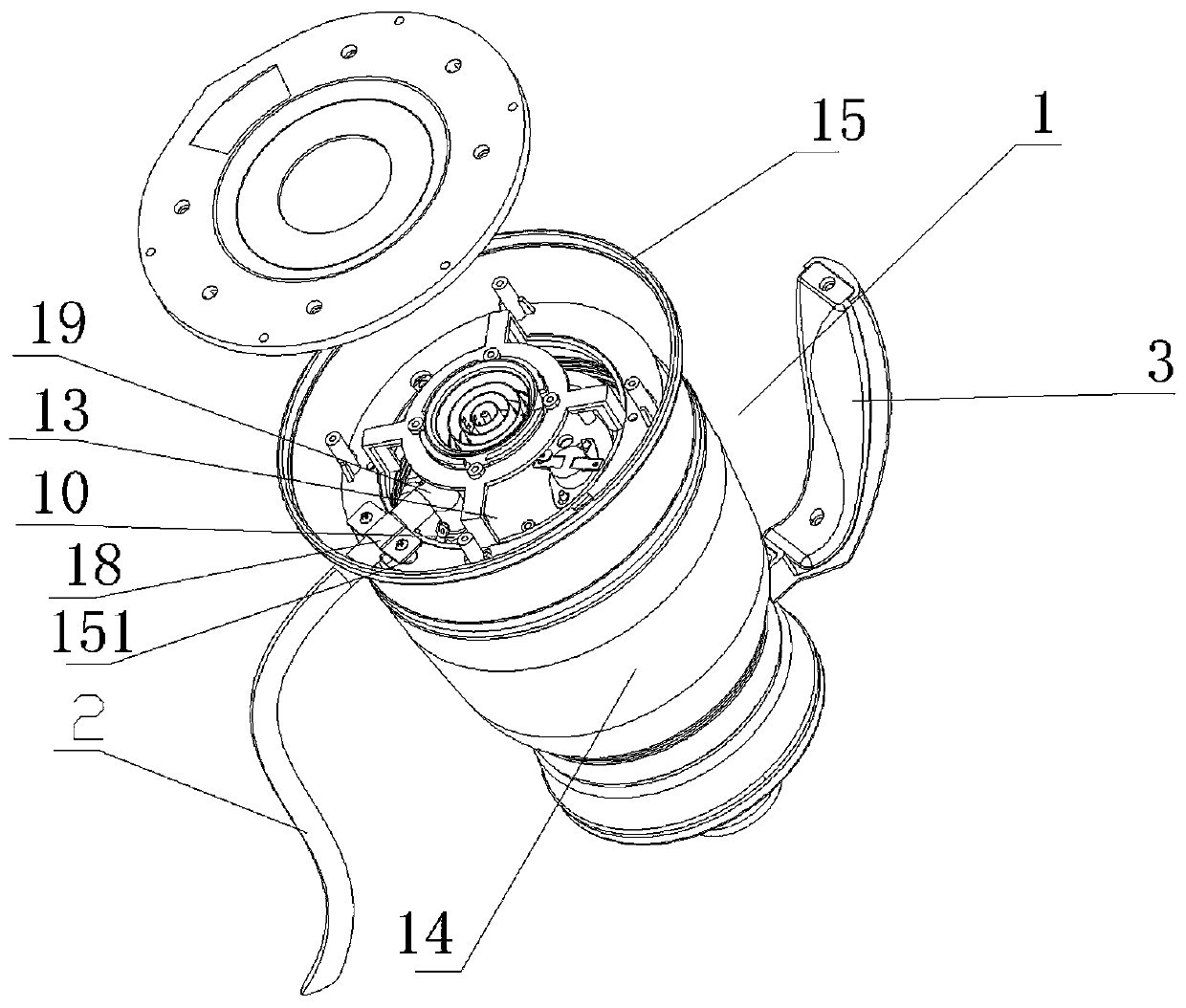

[0018] Such as Figure 1-Figure 3 As shown, the electric kettle of the present invention includes a kettle body 1, a spout 2, and a handle 3 and a kettle lid 5 are mounted on the kettle body 1. The present invention has two technical solutions belonging to the same concept (water is discharged from the bottom of the kettle body): One technical solution is that the bottom of the kettle body 1 (generally the bottom of the inner cavity of the kettle) is provided with a water outlet hole 11, and the inner end of the spout 2 is directly inserted into the water outlet hole from the bottom surface or the side wall of the bottom of the kettle body. 11 are connected; in order to make its structure more reliable and more convenient to install, another technical solution is: the bottom of the inner cavity of the kettle body 1 is provided with a water outlet 11, and a water outlet 12 is installed at the water outlet 11, and the inside of the kettle mouth 2 The end is connected with the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com