Supported auto-balancing self-service type pumping unit

An automatic balancing and pumping unit technology, which is applied to the automatic control system of drilling, production fluid, drilling equipment, etc. It can solve the problems of damage or fracture of components, the inability to equal the weight of the tail load of the pumping unit, and the inability to obtain load balance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

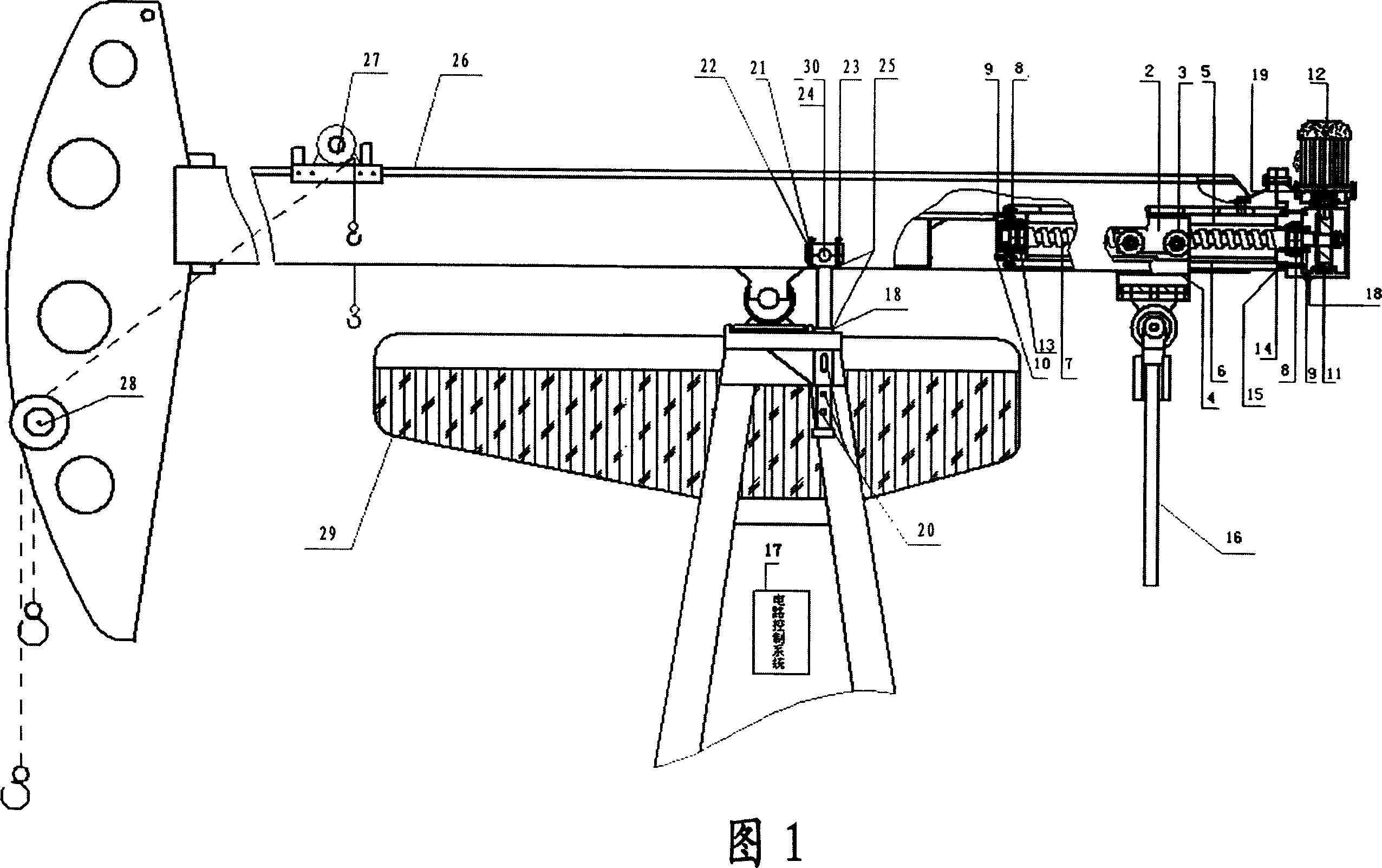

[0009] Referring to Fig. 1 , it is a novel oil pumping unit with automatic load balance of the present invention, which includes a load balance adjustment device 1 at the end of the beam, including a balance sliding body 2 at the end of the beam. At least one rolling shaft wheel 3 is arranged on the balance sliding body. The connecting block 4 of the tail shaft is connected under the balance sliding body. At least one slideway 5, 6 is arranged above and below the balance slider at the tail of the beam, and at least one power rod 7 passing through the balance slider is arranged in the middle of the balance slider at the tail of the beam. At least one positioning bearing, an oil seal and bearing glands 8, 9 are respectively provided at both ends of the power rod. At least one fastening bolt 10 is arranged on the bearing gland. At least one turbine transmission power system 11 is arranged at the tail of the power rod of the balancing slide body. The turbine variable speed powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com