Insulated wire, coil and electrical or electronic equipment

a technology of insulated wires and coils, applied in the direction of insulated conductors/cables, insulated conductors, cables, etc., can solve the problems of high partial discharge inception voltage, high dielectric strength, and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

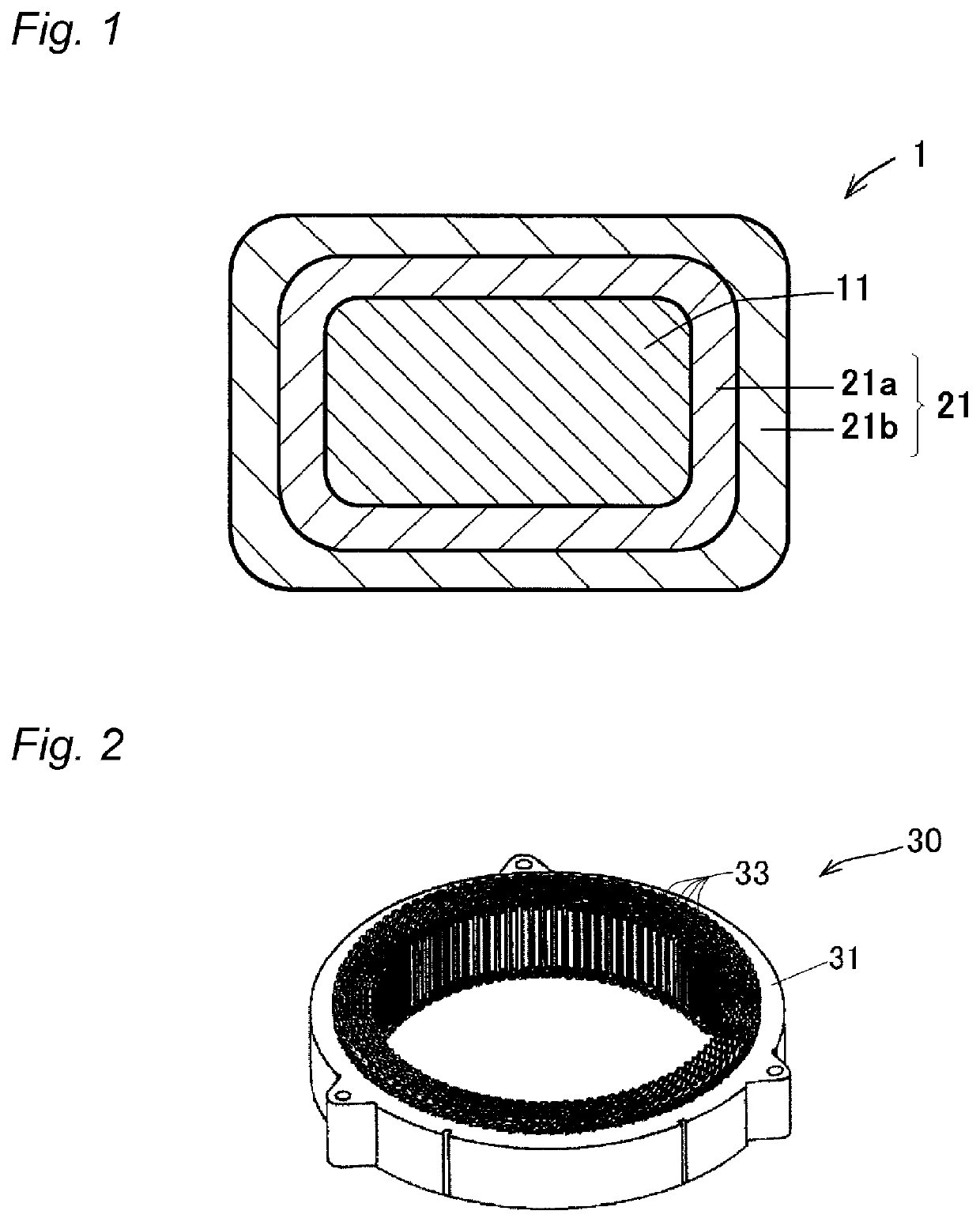

[0174]A rectangular conductor having rectangular cross-section (long side 3.2 mm×short side 1.5 mm, curvature radius of chamfered edge at four corners r=0.3 mm) (copper having an oxygen content of 15 ppm) was used.

[0175]A polyimide (PI) varnish [trade name: U-IMIDE, manufactured by Unitika Ltd., relative permittivity: 3.2] was applied on the surface of the conductor 11 using a die having a cross-sectional shape similar to that of the conductor, and the wire was passed through the interior of a natural convection type firing furnace having a furnace length of 5 m and having the temperature inside the furnace set to 300° C. to 500° C. at a speed that provided a passage time of 5 to 10 seconds. This operation was repeated several times to form an enamel insulating layer formed from a thermosetting resin having a thickness of 60 μm, and thus an enamel wire was obtained.

[0176]With the obtained enamel wire as a core wire, an extruded insulating layer composed of a thermoplastic resin was ...

examples 2 and 3

[0178]Insulated wires composed of one enamel insulating layer and one extruded insulating layer on the conductor were produced in the same manner as in Example 1, except that the resin having the relative permittivity as described in the Table 1 was used, and the thicknesses of the enamel insulating layer and the extruded insulating layer were changed as shown in the Table 1.

example 4

[0179]A polyimide (PI) varnish [trade name: U-IMIDE, manufactured by Unitika Ltd., relative permittivity: 3.2] was applied on the surface of the same conductor 11 as in Example 1 using a die having a cross-sectional shape similar to that of the conductor, and the wire was passed through the interior of a natural convection type firing furnace having a furnace length of 5 m and having the temperature inside the furnace set to 300° C. to 500° C. at a speed that provided a passage time of 5 to 10 seconds. This operation was repeated several times to form a first enamel insulating layer formed from a thermosetting resin having a thickness of 75 μm.

[0180]A PEI varnish obtained by dissolving a polyetherimide PEI [trade name: ULTEM, manufactured by SABIC, relative permittivity: 3.5] in N-methyl-2-pyrrolidone (NMP) was applied on the surface of the first enamel insulating layer using a die having a cross-sectional shape similar to that of the conductor, and the wire was passed through the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap