Sensor package structure

a sensor and package technology, applied in the field of package structure, can solve the problems of air bubbles within the gap in the conventional sensor package structure, defects in the package structure, and difficult to completely fill, so as to achieve the effect of improving the problem associated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

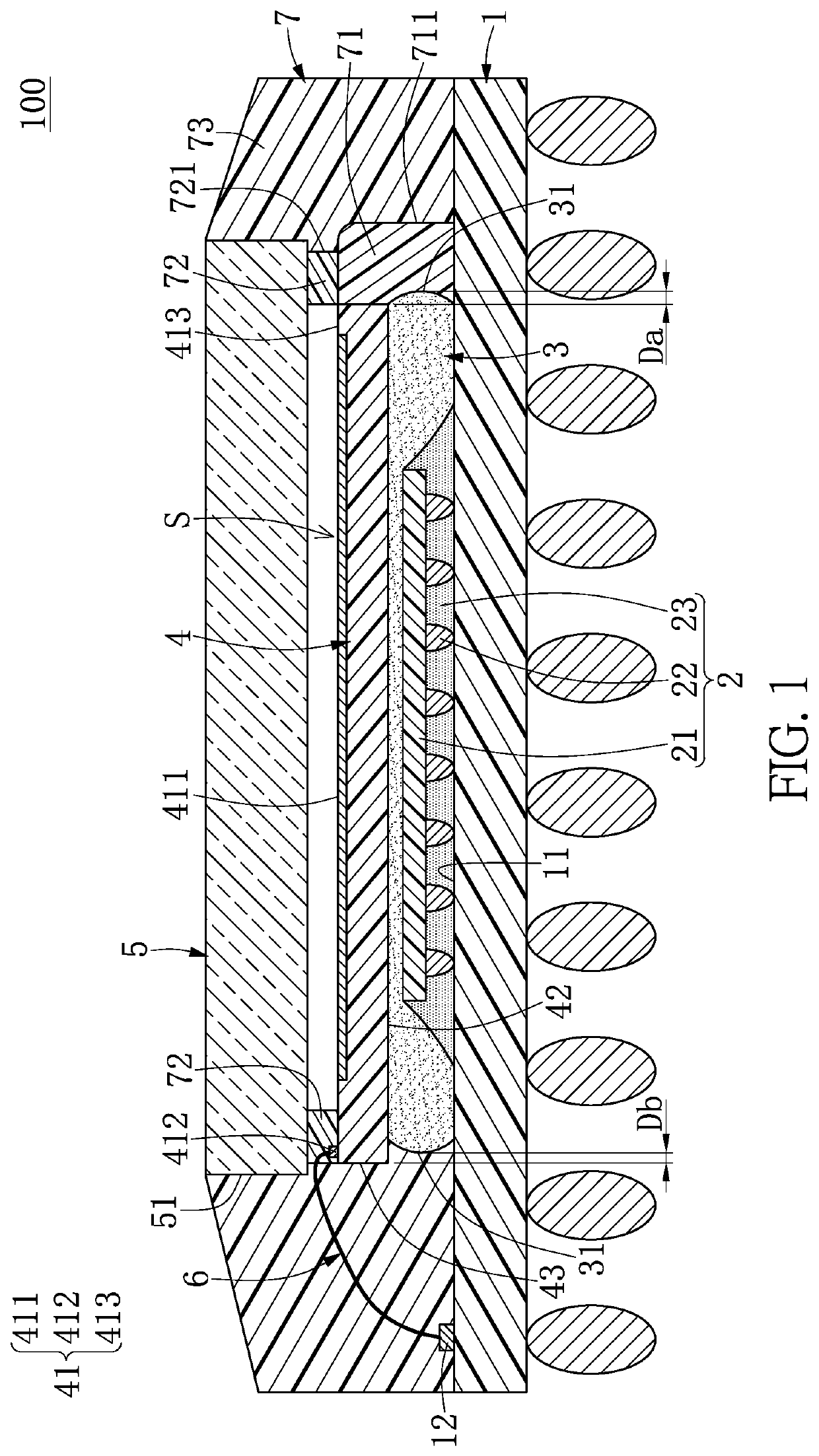

[0014]Please refer to FIG. 1, which illustrates the first embodiment of the disclosure. The first embodiment discloses a sensor package structure 100 that includes a substrate 1, an electronic chip 2 fixed on the substrate 1 by flip-chip bonding, a sealant 3 disposed on the substrate 1 and entirely embedding the electronic chip 2, a sensor chip 4 disposed on the sealant 3, a light-permeable sheet 5 corresponding in position to the sensor chip 4, a plurality of metal wires 6 electrically connecting the substrate 1 and the sensor chip 4, and a package body 7 disposed on the substrate 1.

[0015]It should be noted that FIG. 1 is presented as a cross-sectional view in order to clearly show the sensor package structure 100 of the embodiment. However, it should be realized that the portion of the sensor package structure 100 not shown in the drawing should have corresponding structures similar or identical to those in FIG. 1. For example, FIG. 1 only shows one of the metal wires 6, but the p...

second embodiment

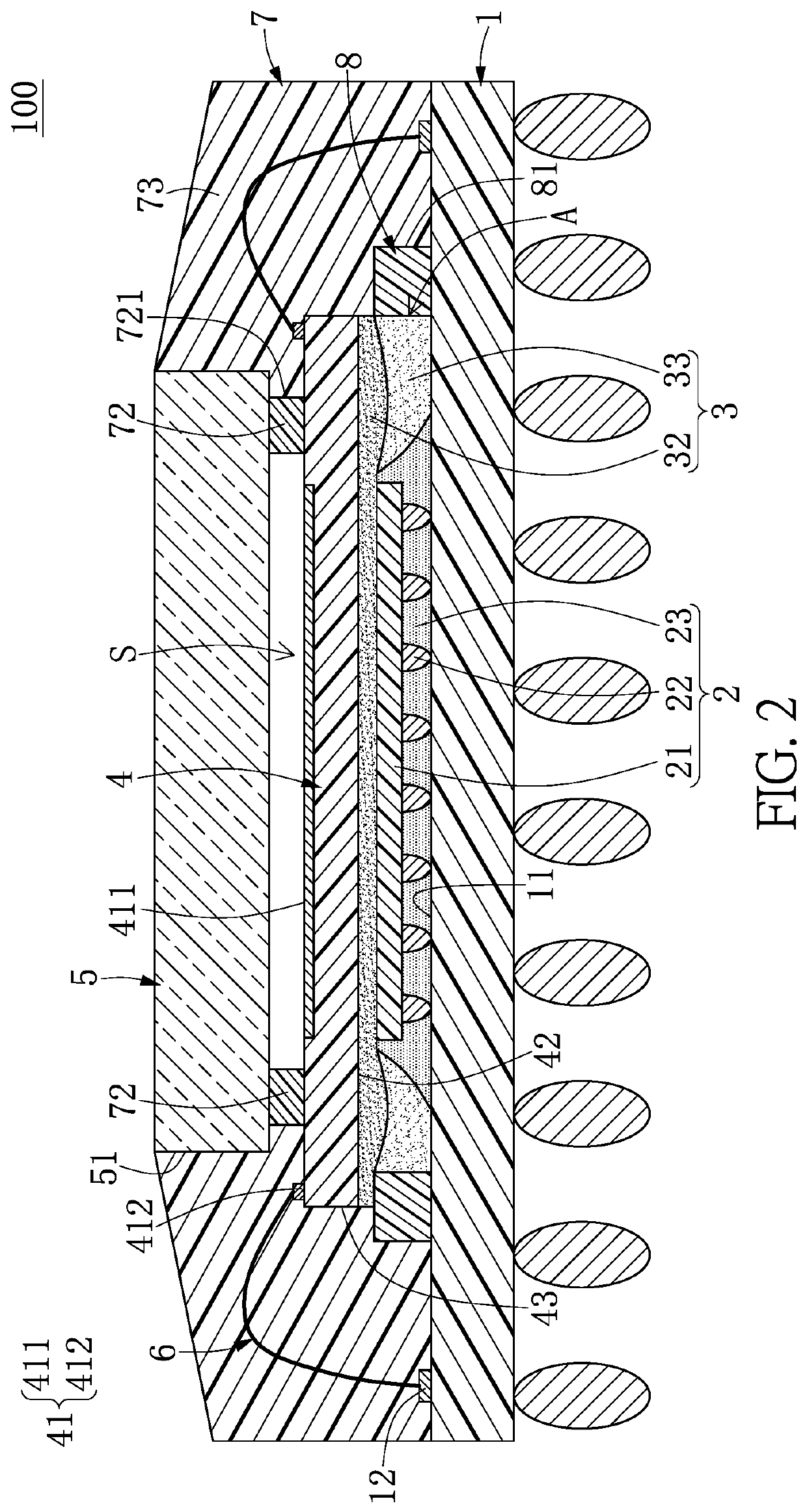

[0037]A reference is made to FIG. 2 which shows a second embodiment of the disclosure. The present embodiment is similar to the first embodiment, the common points between the embodiments shall not be recited again, and the main distinction of the embodiment differing from the first embodiment is described as follows. The sensor package structure 100 in this embodiment further includes a retaining wall 8, the sealant 3 includes a bottom layer 32 and an adhesive layer 33, and some components of the sensor package structure 100 are disposed in correspondence to the retaining wall 8.

[0038]Specifically, the retaining wall 8 in the embodiment is ring-shaped, and the retaining wall 8 is disposed on the substrate 1 to encompass an accommodating space A therein. The electronic chip 2 is arranged in the accommodating space A and mounted on the substrate 1 by flip-chip bonding. The bottom layer 32 is filled in the accommodating space A and surrounds an annular lateral side of the electronic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com