Double-acting friction stir spot welding method and apparatus

a friction stir and spot welding technology, applied in welding apparatus, metal-working equipment, manufacturing tools, etc., can solve the problems of deteriorating a manufacturing efficiency of the welded body, increasing the weight of the workpiece, etc., and achieve the effect of increasing the thickness of the build-up portion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

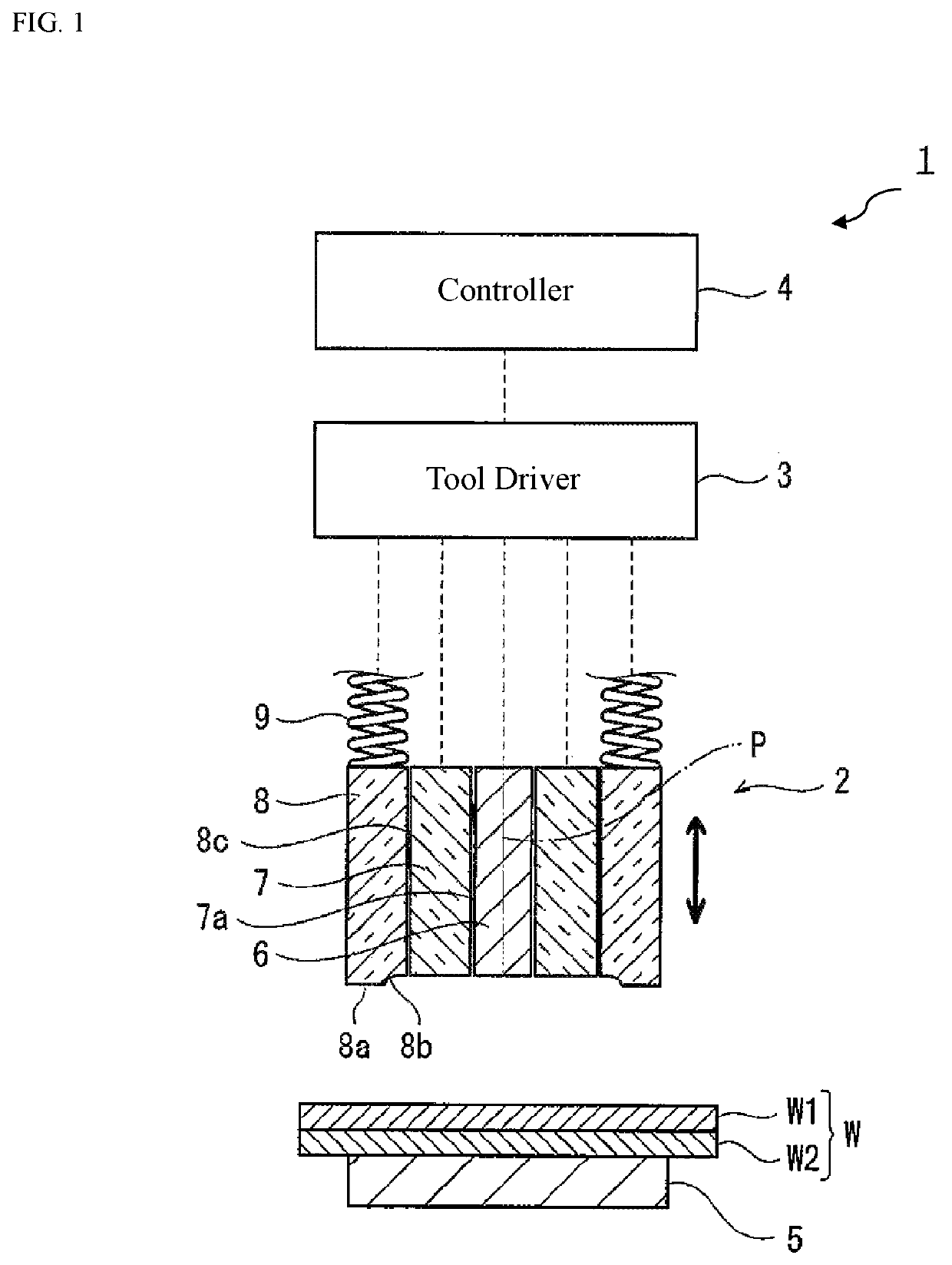

[0020]FIG. 1 shows a configuration of a main part of a double-acting friction stir spot welding device 1 (referred to as the device 1 hereinafter) according to the first embodiment. Referring to FIG. 1, a rotary tool 2 is shown in cross section, and a connection between the rotary tool 2 and a tool driver 3 is schematically indicated by broken lines.

[0021]The device 1 performs friction stir spot welding of workpieces W (for example, a pair of plate materials (a first plate material W1 and a second plate material W2)). The device 1 includes the rotary tool 2, the tool driver 3, a controller 4, a backing portion 5, and a clamp member 8.

[0022]The tool driver 3 moves the rotary tool 2 to a plurality of predetermined positions and drives the rotary tool 2 to rotate. The controller 4 controls the tool driver 3 so as to drive members 6 to 8 included in the rotary tool 2. The specific structure of the tool driver 3 is not limited, and for example, a known structure can be used.

[0023]The con...

second embodiment

[0076]FIG. 7 illustrates a view showing the configuration of the main part of a double-acting friction stir spot welding device according to the second embodiment. This embodiment differs from the first embodiment in that a backing portion 15 has a concave portion 15a formed in the surface facing the workpiece W so as to be recessed in the axis P direction. The concave portion 15a is provided at a position facing a chamber portion 8b with a workpiece W interposed between them, and extends along the surface of the workpiece W.

[0077]For example, the concave portion 15a has a peripheral edge having a circuit shape when viewed in a front view (viewed in the axis P direction). The concave portion 15a has an inclined surface whose inner diameter gradually decreases from the peripheral edge toward the inside of the backing portion 15 in the axis P direction and a bottom surface surrounded by the inclined surface. The inner diameter of the peripheral edge of the concave portion 15a can be s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| plastic flow | aaaaa | aaaaa |

| inner diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com