Wet type buffing method, deposition plating method, work buffing method, work buffing apparatus, barrel buffing apparatus, work surface treating method, work supporting unit for barrel buffing apparatus, and buffing medium

a barrel buffing and buffing technology, applied in the direction of flexible parts wheels, manufacturing tools, edge grinding machines, etc., can solve the problems of difficult to improve the buffing efficiency of the conventional buffing method, the oxide film or the like can be removed from the surface of the work only with much difficulty, and the inconvenience inherent in the wet type buffing operation, so as to eliminate the inconvenience inherent, smooth buffing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment of first invention

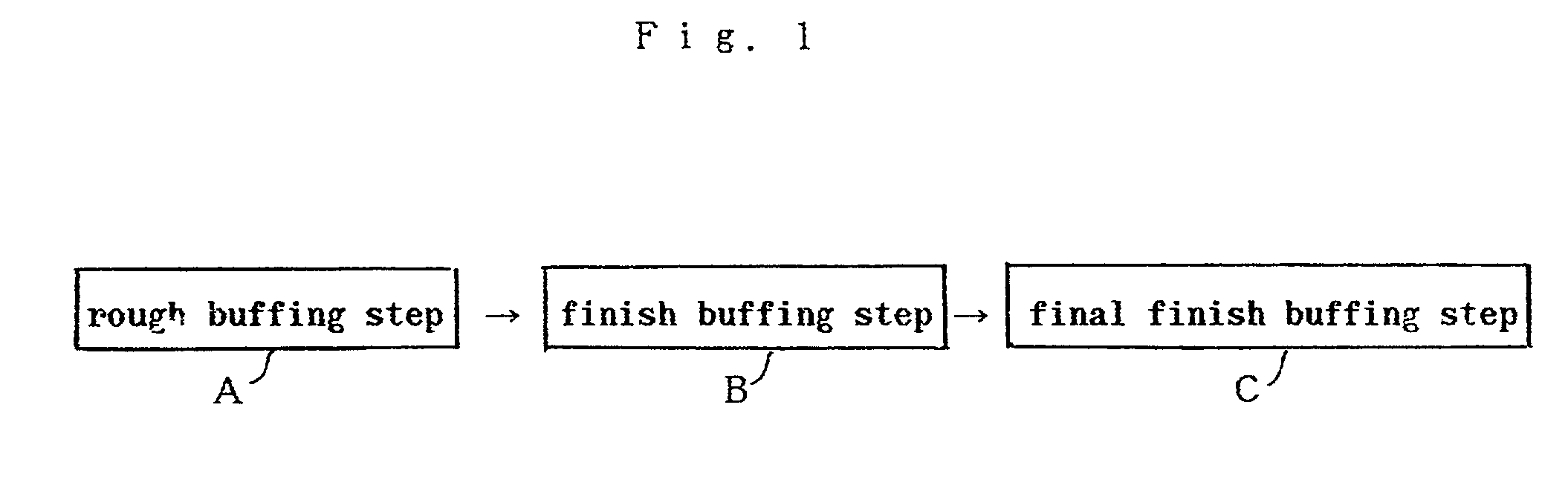

[0082] FIG. 1 shows an embodiment of a wet type buffing method to be practiced according to the present invention, and this buffing method is practiced by way of a series of wet type buffing steps.

[0083] A step A represents a rough buffing step, a step B represents a finish buffing step, and a step C represents a final finish buffing step.

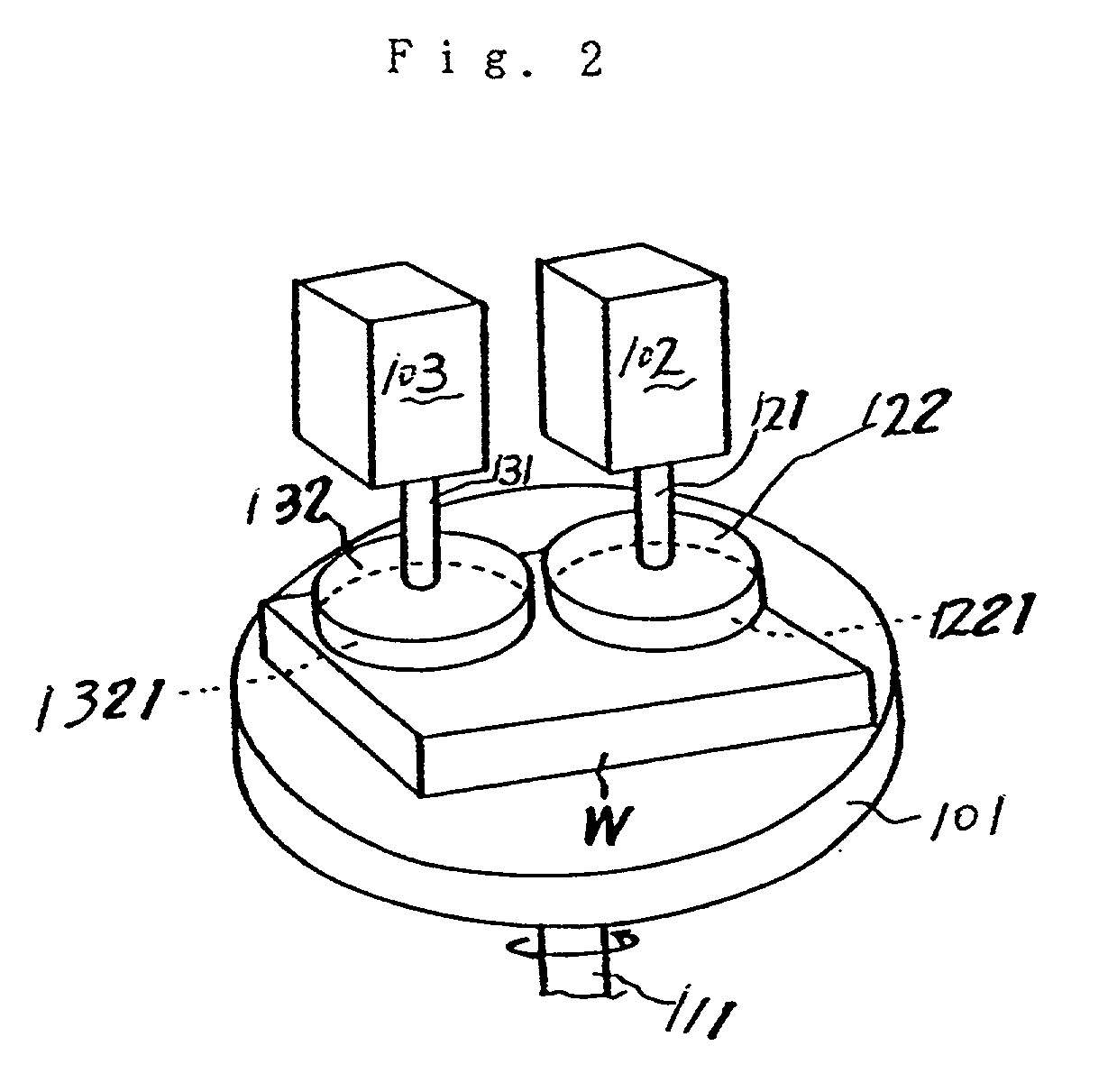

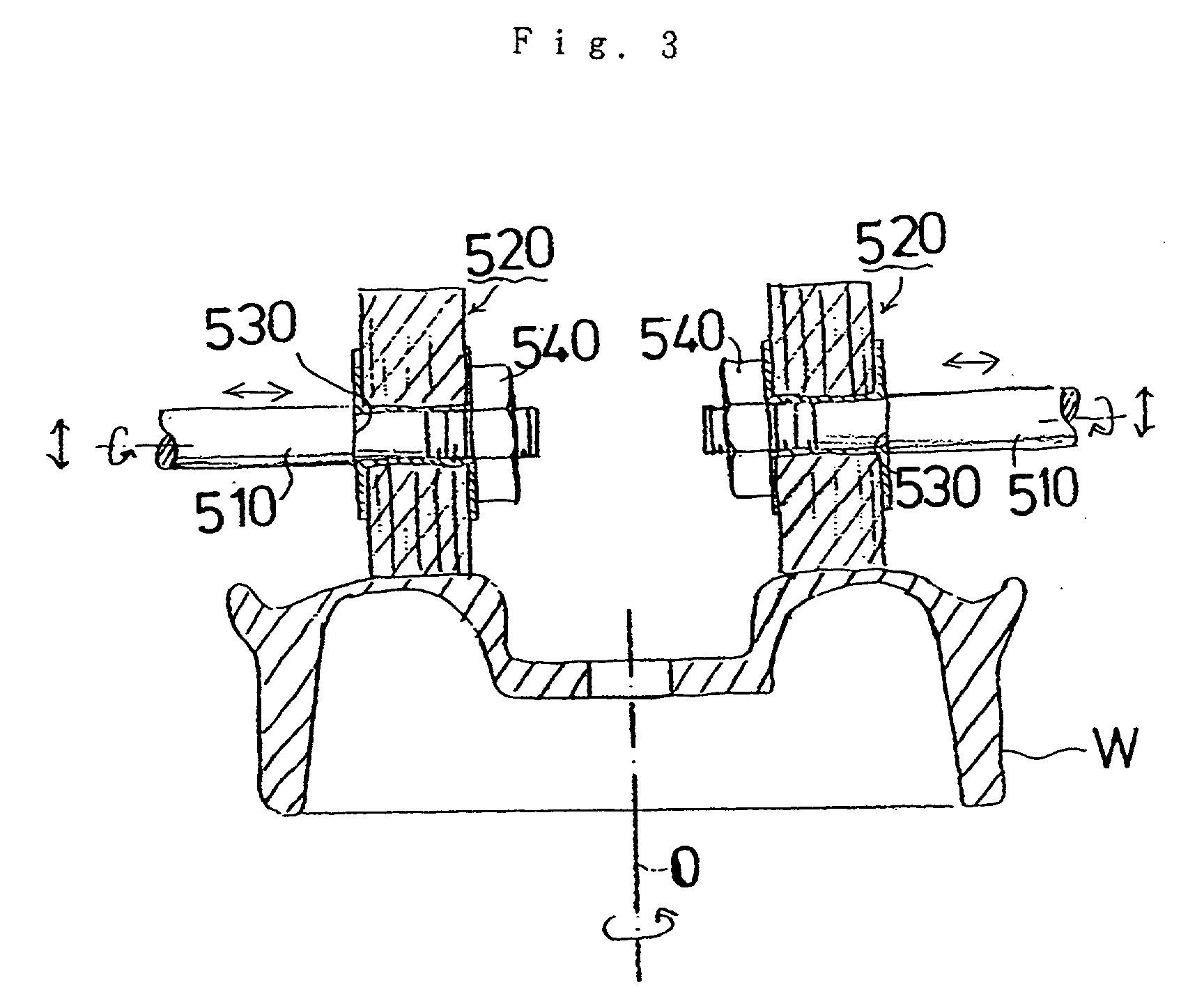

[0084] These steps A, B and C will be described below with reference to FIG. 2. In the drawing, reference numeral 101 designates a supporting board, and reference numeral 111 designates a supporting shaft arranged along the axis line of the supporting board. The supporting board 101 is rotated about the supporting shaft 111 with the use of suitable means (not shown) in the direction identified by an arrow mark. Reference character W designates a plate-like work, and this plate-like work is placed on the upper surface of the supporting board 101. In the shown case, the work W serves as a surface to be buffed (hereinafter referred to as a buffing sur...

embodiment of second invention

[0088] This second invention will be described below with respect to an embodiment thereof on the assumption that an aluminum wheel is employed as a work.

[0089] Firstly, the aluminum wheel is heated in hot water at a temperature of about 80.degree. C., and then, it is subjected to dry buffing by employing the ordinary method. Thereafter, the aluminum wheel is subjected to wet buffing while maintaining the working state represented by a temperature of about 30.degree. C.

[0090] After the buffing operation is completed, the aluminum wheel is subjected to deposition plating by employing the ordinal deposition plating method. Any type of deposition plating such as chromium deposition plating, titanium deposition plating or the like may be employed for the aluminum wheel. It should be noted that the thickness of a film formed by the deposition plating generally remains within the range from about 0.1 .mu.m to 0.2 .mu.m. When the deposition plating is used in place of the conventional chro...

embodiment of third invention

[0091] For example, an aluminum wheel usable for a vehicle or the like can be noted as a work employable for carrying out this third invention. However, the third invention should not be limited only to the aluminum wheel as a work but all products each usable as a work are involved in the concept of the work in the third invention.

[0092] Usually, a wet type buffing method or a dry type buffing method for buffing the buffing surface of a work in the presence of a buffing agent is employed as a buffing method in the third invention. In this case, the number of buffs usable for carrying out the third invention may be limited only to one. Alternatively, a plurality of buffs may be used for carrying out the third invention. Incidentally, a buff wheel can be noted as one example which represents the buff.

[0093] To carry out the third embodiment, an ordinary wet type buffing method and an ordinary dry type buffing method can be employed for practicing the wet type buffing method and the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com