Process and apparatus for mechanically joining metallic components

a technology of mechanical joining and metallic components, which is applied in metal working apparatuses, manufacturing tools, and shape safety devices, etc., can solve the problem that the joining process to be carried out by this apparatus cannot be done in the operation area, and achieve the effect of low profil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

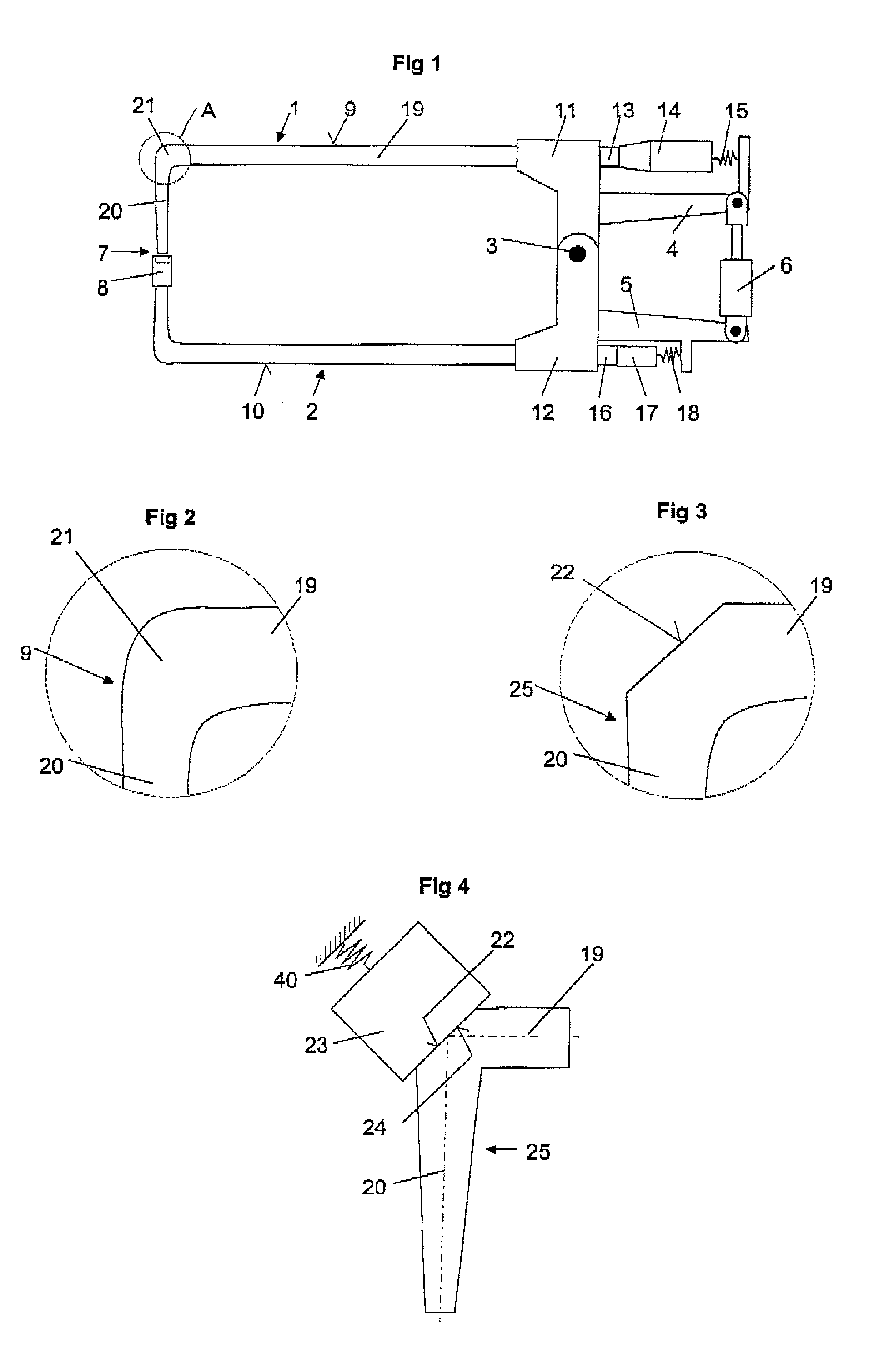

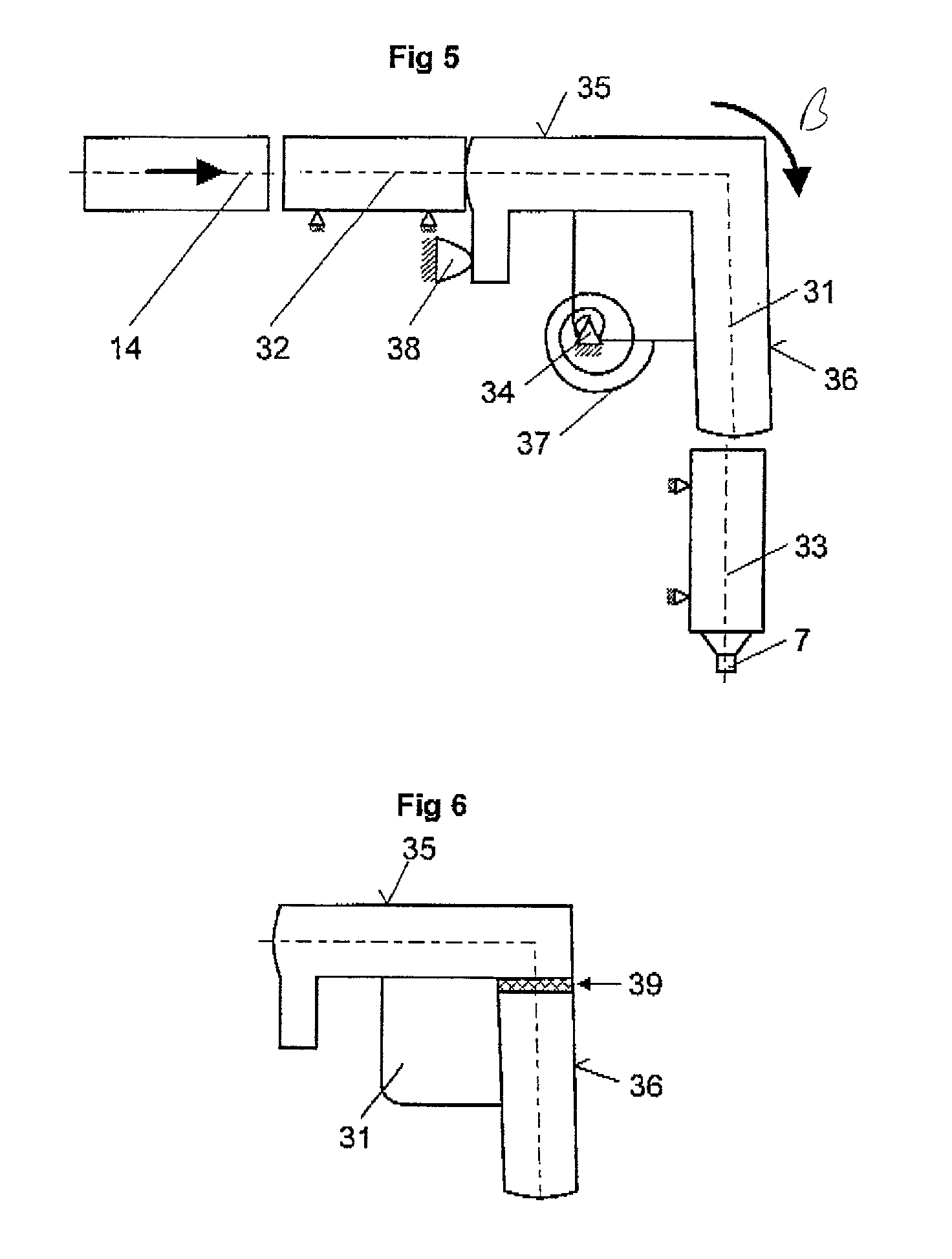

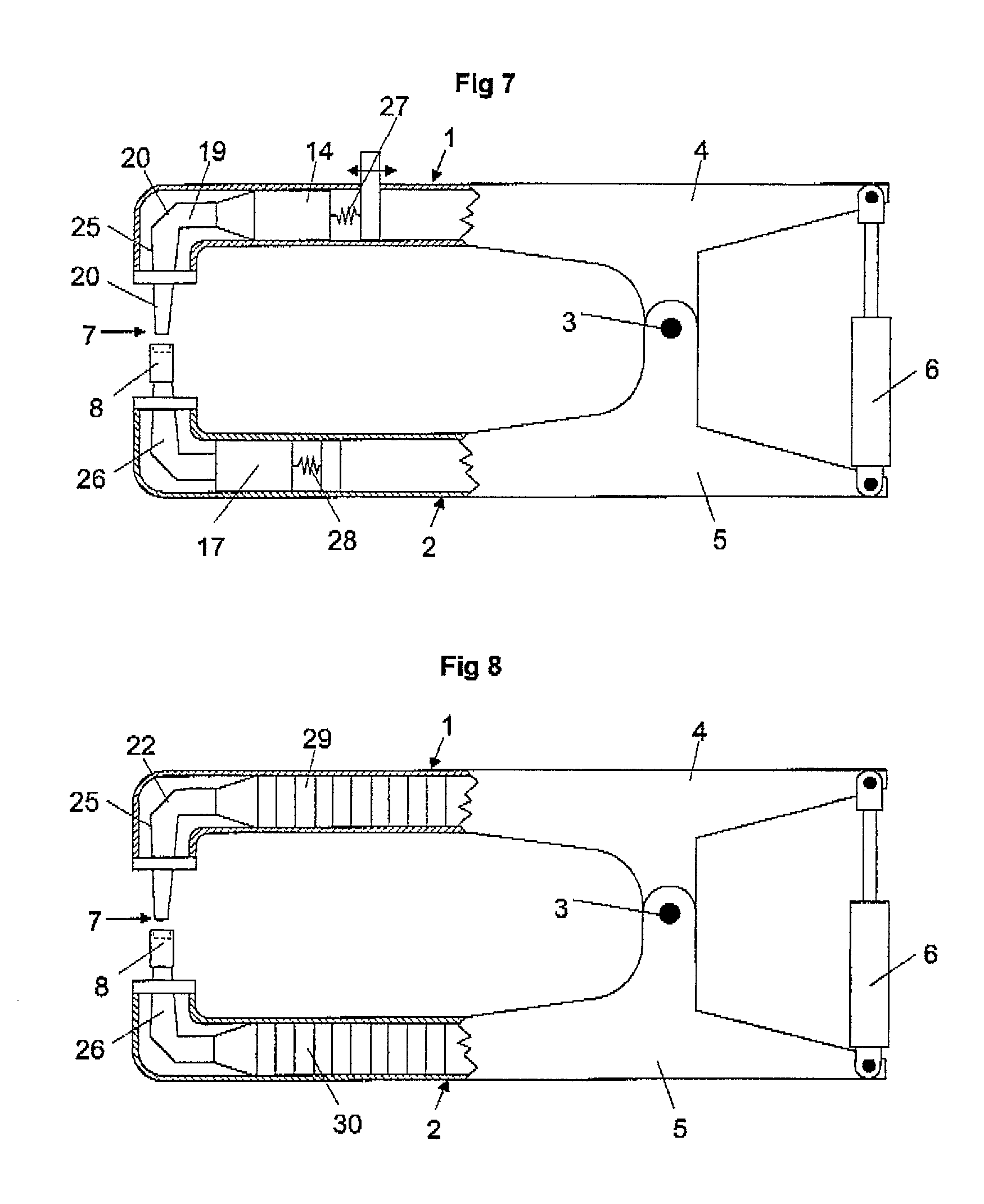

[0026] Each embodiment of a joining apparatus shown in FIGS. 1, 7 and 8 is structured in the manner of shears, with an upper tong arm 1 and a lower tong arm 2 being pivotally coupled to one another at a rotation point 3. End portions 4 and 5 of the upper as well as the lower tong arms 1 and 2 extend beyond the rotation point 3. A motivating unit 6 is arranged between these two end portions 4 and 5 for opening forward tong ends and moving them back together. Such a shearing-tong, with the above described arrangement of the motivating unit, with the motivating unit being arrange behind a center of gravity of the shearing tongs, makes possible a narrow structure for the joining apparatus and improves its maneuverability by having a favorable distribution of its masses.

[0027] In the embodiment of FIG. 1, each of the upper tong arm 1 and the lower tong arm 2 forms a ram, or impulse, wave conductor 9, 10. These impulse-wave conductors 9 and 10 pass rearward through holders 11, 12 that sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrical resistance | aaaaa | aaaaa |

| Metallic bond | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com