Method of fabrication of a microstructure having an internal cavity

a microstructure and internal cavity technology, applied in the field of fabricating a microstructure having an inside cavity, can solve the problems of difficult electrical contact, incompatibility with these boundary conditions, and limited applicability, and achieve excellent hermetic seal of the cavity and facilitate the making of the indent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

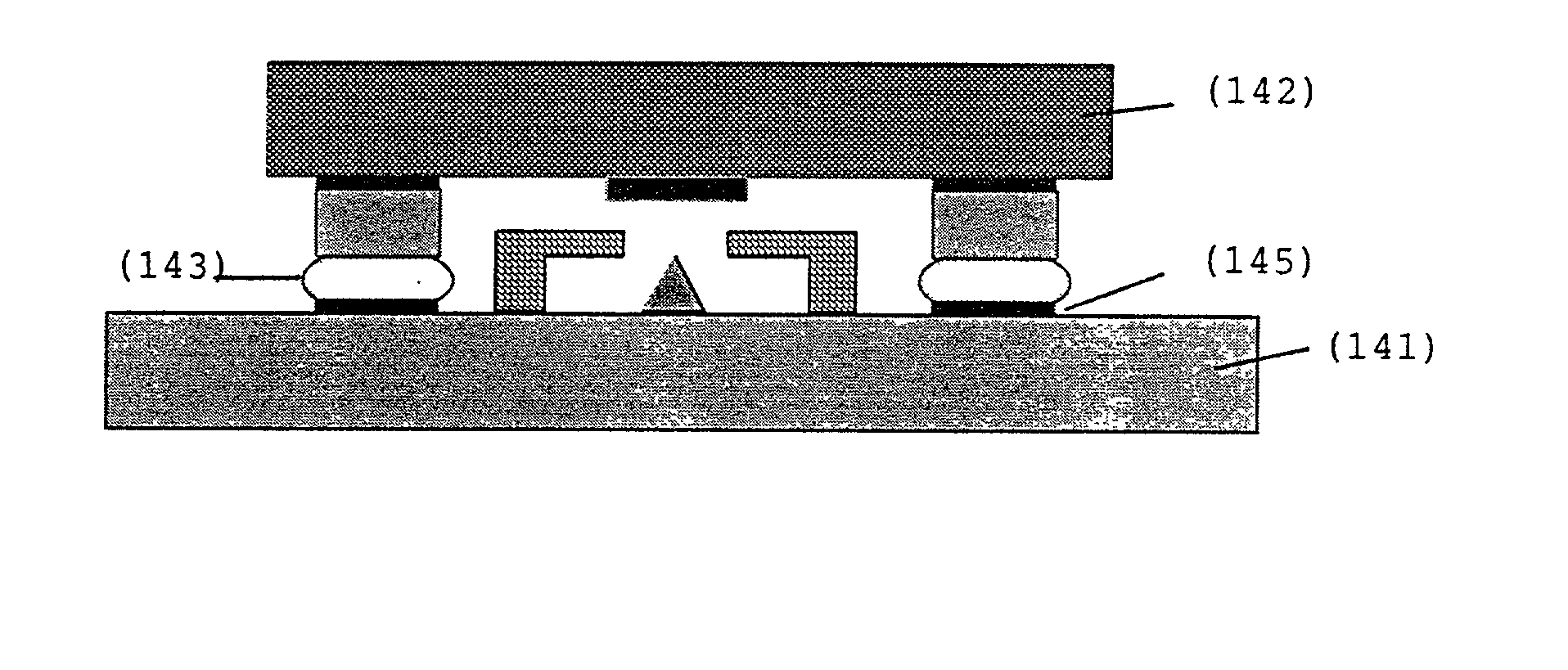

[0076] An integral design and fabrication approach incorporating all the key elements of a micro-relay, i.e., actuator, electrical contacts, housing of the electrical contacts, structural design, micro-machining fabrication process and packaging, has resulted in the micro-relay schematically shown in FIG. 16. The heart of the micro-relay comprises two "flip-chip assemblied" chips (161) using the method of the present invention described hereabove.

[0077] The assembly process is based on the eutectic (162) bonding between electroplated tin lead (SnPb) and gold (Au) layers. One of the two chips of the assembly uses a ferromagnetic substrate (161) and comprises a U-core electromagnet, consisting of a double-layer Cu coil (cross section Cu winding 6.times.8 .mu.m.sup.2, total number of turns N=127), electroplated NiFe (50 / 50) poles (1.times.0.15 mm.sup.2), and the lower electrical contact. The upper chip (162) uses an oxidised silicon substrate. The chip accomodates an armature consistin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com