Method of encapsulation

a gelatin capsule and encapsulation technology, applied in the field of encapsulation, can solve the problem of very limited sales of gelatin capsules

Inactive Publication Date: 2002-03-07

BIOPROGRESS TECH

View PDF0 Cites 40 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

[0011] It is preferred to use film material that becomes more flexible when in partially solvated conditions as this assists capsule formation. PVA has this property.

Problems solved by technology

As a result, the sales of such gelatin capsules are very limited among such individuals.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example

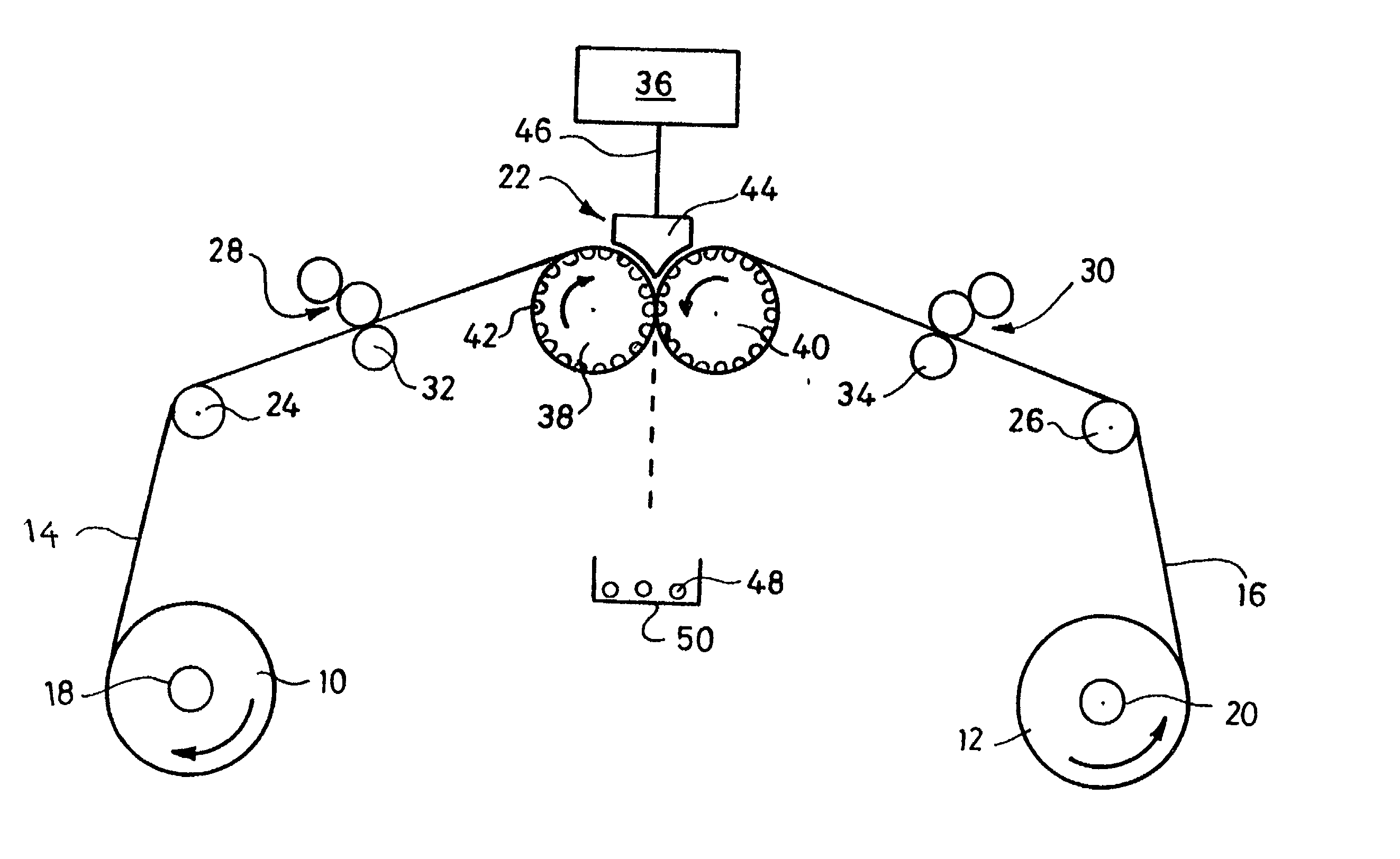

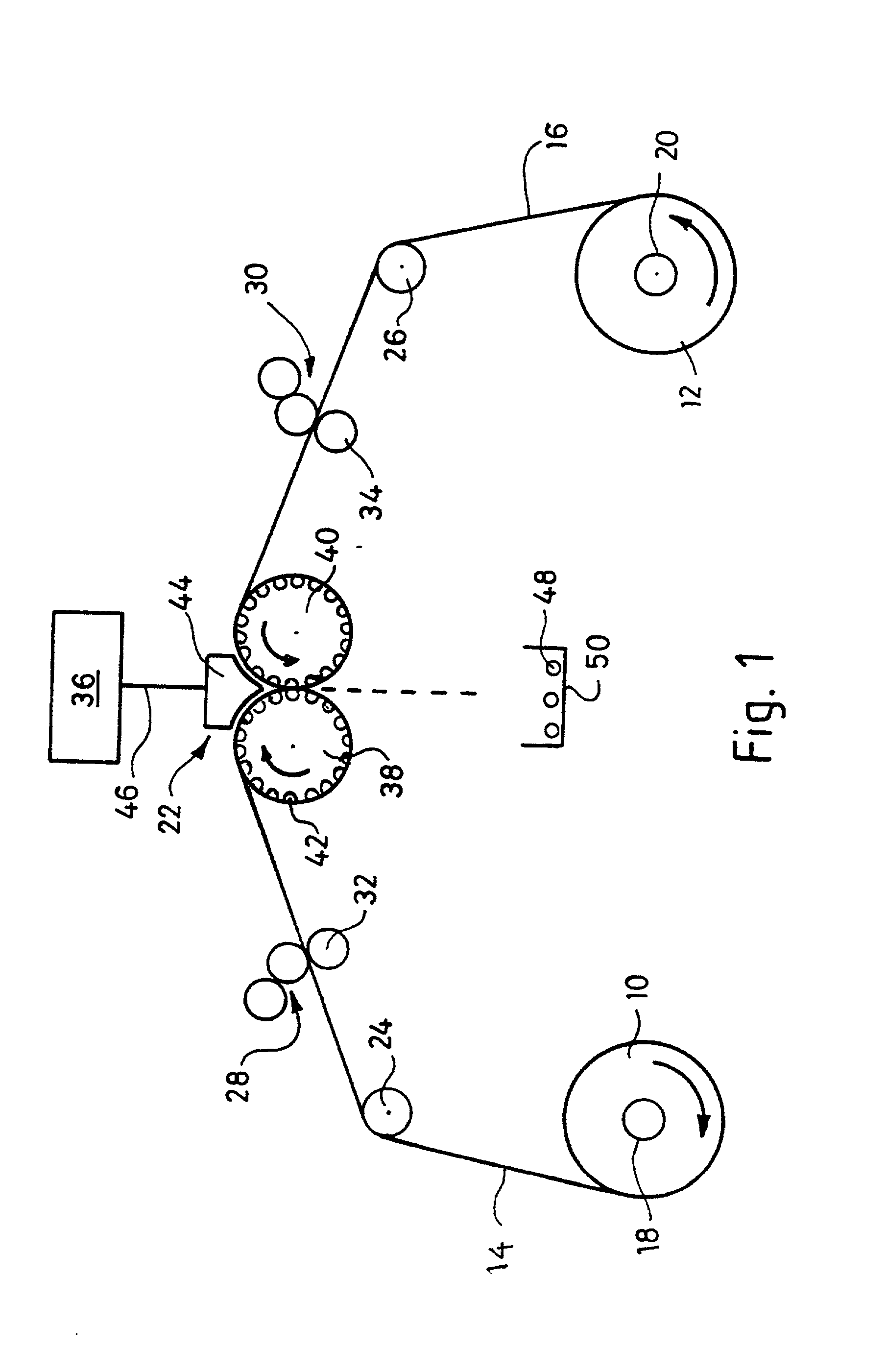

[0040] Using the apparatus of FIG. 1 encapsulation of a typical bath oil cosmetic product was carried out using Hi-Selon cold water soluble plasticised polyvinyl alcohol (B9) film, 80 micron thick, with partial solvation carried out by application of water. This resulted in production of good quality capsules, suitable for cosmetic use.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexibility | aaaaa | aaaaa |

| Adhesivity | aaaaa | aaaaa |

| Vacuum | aaaaa | aaaaa |

Login to View More

Abstract

A method of encapsulation is characterized by supplying to an encapsulation unit (22) two films (14, 16) of like material capable of deforming elastically at least when partially solvated, and applying solvent to at least one of the films prior to encapsulation to cause partial solvation of the material surface, such that the partially solvated surface can adhere to and seal with the film material. In the encapsulation unit, the substance to be encapsulated e.g. a cosmetic oil or vitamin preparation is supplied between the films, the films are formed, typically by a molding process, into suitably shaped capsule portions which can adhere to each other as a result of the adhesive action of the partially solvated surface(s), and which seal together encapsulating the supplied substance, forming a capsule. The invention enables encapsulation using materials other than gelatin, such as polyvinyl alcohol. Also disclosed is encapsulation apparatus and the resulting capsules.

Description

[0001] This invention concerns encapsulation and relates to a method of encapsulation, encapsulation apparatus and the resulting capsules.BACKGROUND TO THE INVENTION[0002] The provision of water soluble and digestible capsules containing pharmaceutical or cosmetic preparations is well established. Typically oils are encapsulated in gelatin shells designed to release their contents when subjected to immersion in water or exposure to digestive juices. These oils include dietary enhancement substances or, in the case of cosmetic preparations, fragrant oils for release into bath water. A substantial industry has been built up around this principle, based primarily on the use of gelatin for the capsule shells. This gelatin is derived from the bones and skins of animals.[0003] With concern for the environment and animal welfare and fear of animal related diseases such as Bovine Spongiform Encephalopathy (BSE) increasing, the number of individuals adopting a serious stance on the use of an...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A61J3/07B65B11/50A61K9/48C08J5/12

CPCA61J3/07A61K8/11A61K8/8129A61K9/4816A61Q19/10C08J5/122

Inventor BROWN, MALCOLM DAVID

Owner BIOPROGRESS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com