Exhaust gas catalyst and method of manufacturing same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

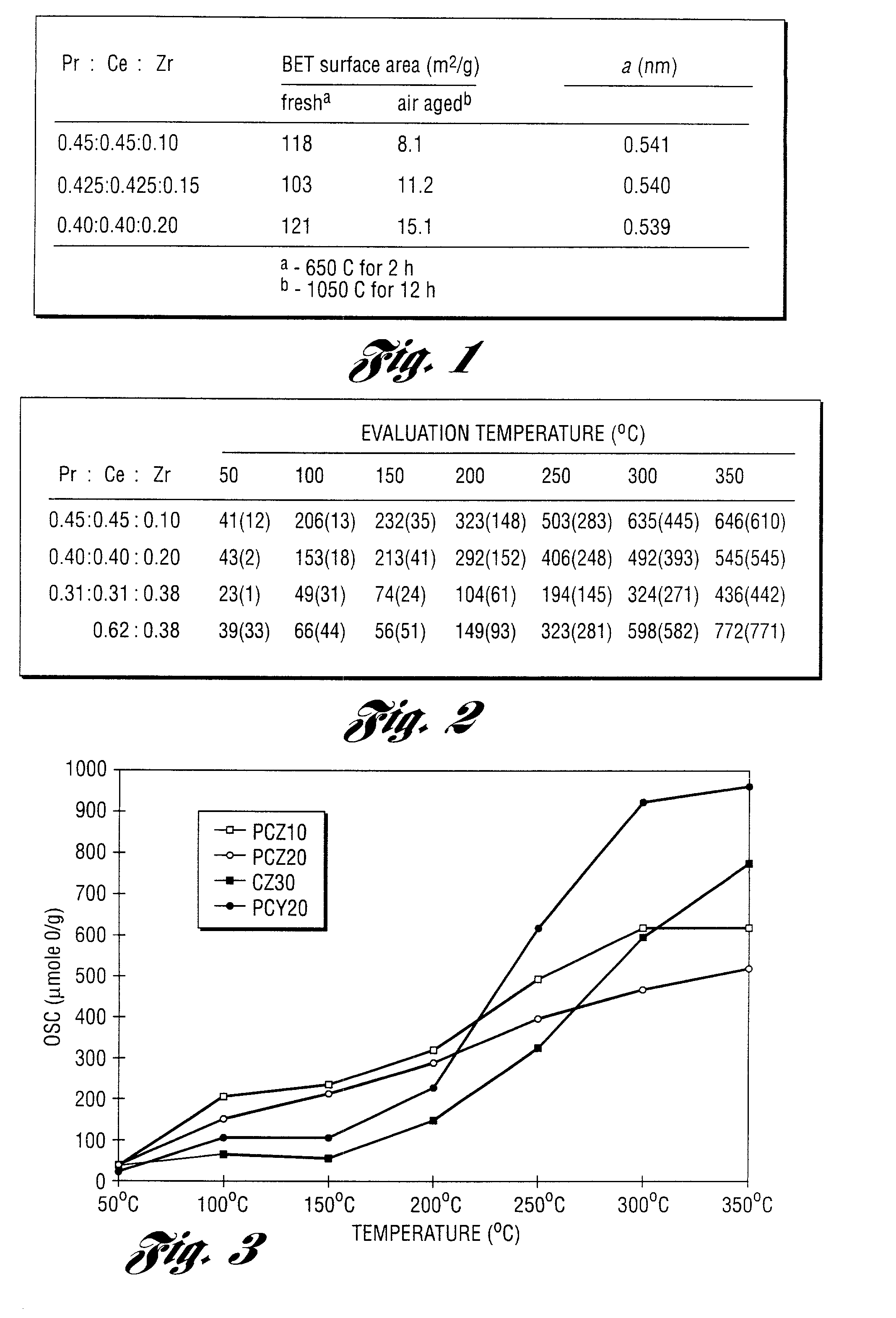

[0039] Praseodymium-cerium oxide mixture is prepared at equally molar contents, specifically 42.5 weight percent each. Fifteen weight percent zirconium was doped to the oxide mixture and 2 weight percent palladium is added thereafter. Gamma alumina is then mixed to the oxide mixture for washcoating and the oxide mixture is then washcoated onto a monolithic substrate, specifically cordierite substrate.

example 3

[0040] Praseodymium-cerium oxide mixture is prepared at equally molar contents, specifically 40 weight percent each. Twenty weight percent zirconium is doped to the oxide mixture and 2 weight percent palladium was added thereafter. Gamma alumina is then mixed to the oxide mixture for washcoating and the oxide mixture is then washcoated onto a monolithic substrate, specifically cordierite substrate.

example 4

[0041] Praseodymium-cerium oxide mixture is prepared at equally molar contents, specifically 31 weight percent each. Thirty-eight weight percent zirconium is doped to the oxide mixture and 2 weight percent palladium was added thereafter. Gamma alumina is then mixed to the oxide mixture for washcoating and the oxide mixture is then washcoated onto a monolithic substrate, specifically cordierite substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Substance count | aaaaa | aaaaa |

| Ratio | aaaaa | aaaaa |

| Content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com