Axial cooling of a rotor

a technology of axial cooling and rotor, which is applied in the direction of magnetic circuit rotating parts, dynamo-electric brake control, magnetic circuit shape/form/construction, etc., can solve the problems of water cooling cost, contribute to ventilation loss, and high cost of water cooling technology, so as to reduce the mass flow of air and reduce the ventilation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

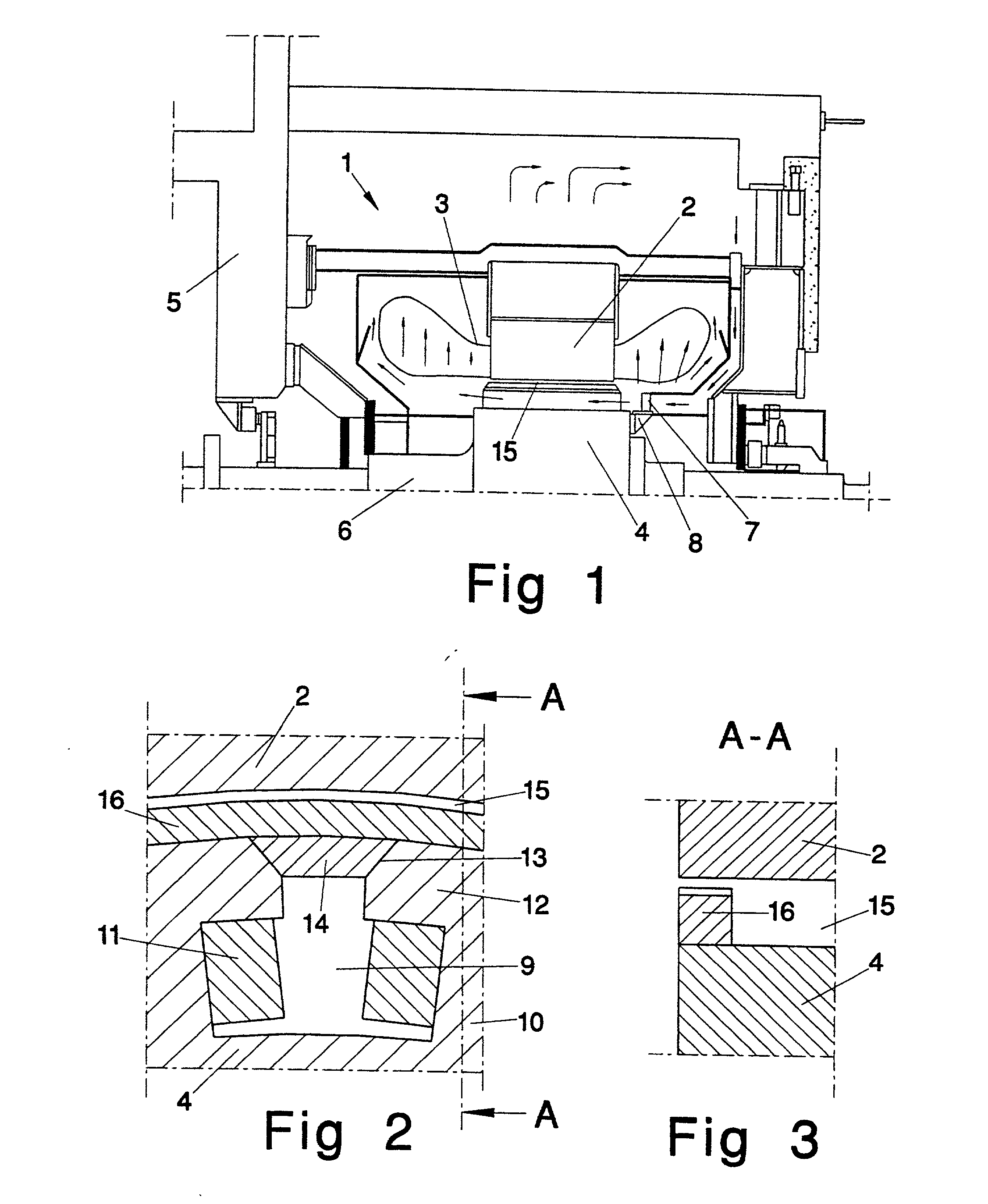

[0010] FIG. 1 shows a rotating electric machine 1 comprising a stator 2 with stator winding 3 which may consist of high-voltage cable. The machine 1 is provided with a rotor 4 arranged on a machine shaft 6 journalled in a machine housing 5. The rotor 4 is also provided with a fan 8 having blades 7. A controlled air flow for axial rotor cooling is indicated by arrows in the Figure. This also shows how the coil end parts of the machine are allowed to be cooled by the air flow. However, the invention is not limited to the embodiment shown in the drawing and according to a different embodiment the coil end parts can be cooled separately to avoid cooling one coil end with heated air. This can also be achieved by two-way axial cooling where each end of the rotor is provided with a fan blowing in air towards the middle of the rotor, the air then leaving through a radial air duct situated in the middle of the stator.

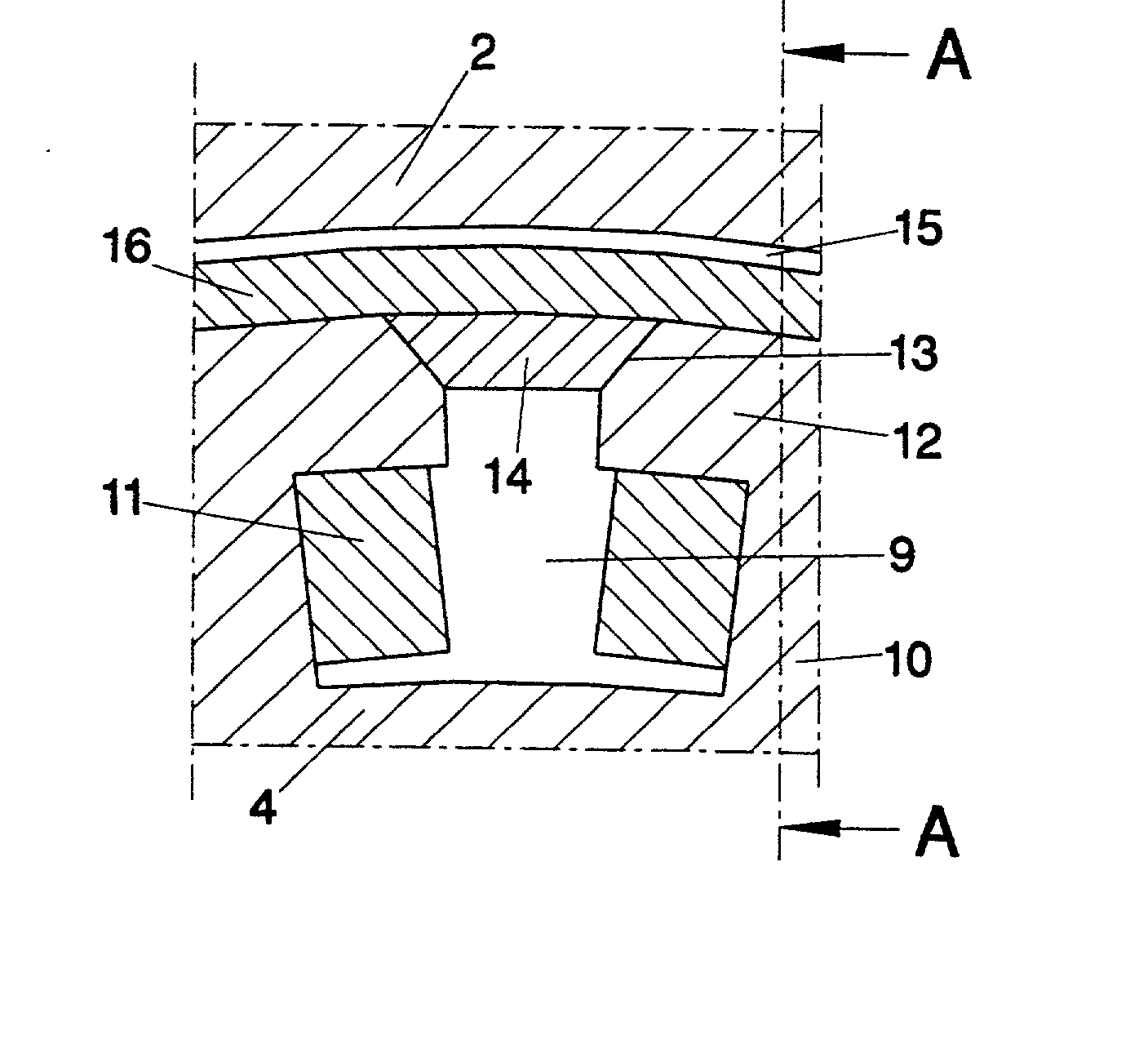

[0011] FIG. 2 shows a partial radial section through the rotor 4 which has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com