Optical position sensor with threshold updated dynamically by interpolation between minimum and maximum levels of output signal

a technology of optical position sensor and threshold, which is applied in the direction of conveyor counting, instruments, pulse technique, etc., can solve the problems of optical sensor unreliability, prone to failure, and moving parts in mechanical switches, etc., and achieves the effect of easy and economical implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

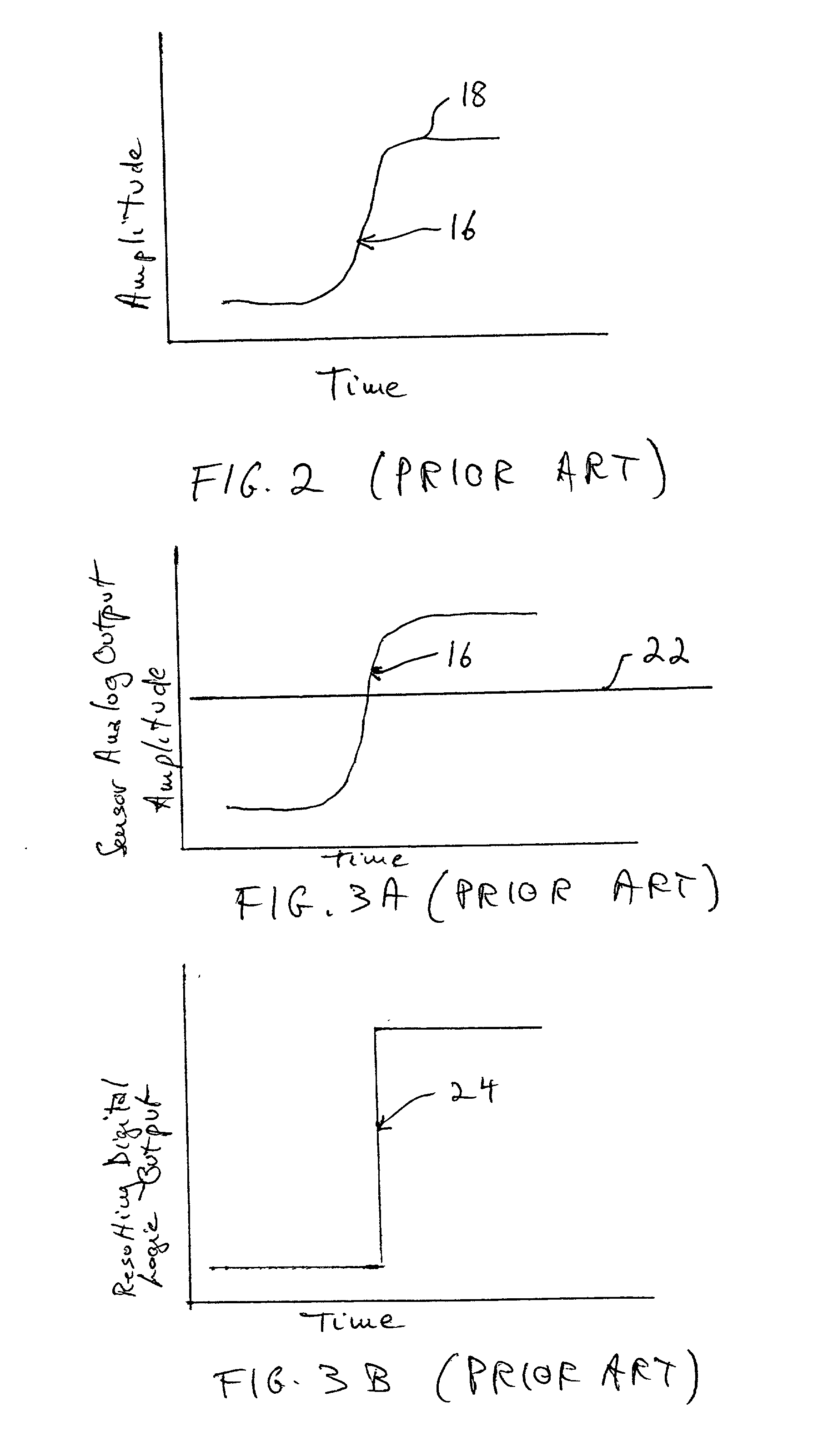

[0038] The heart of this invention lies in the idea of dynamically varying the detection threshold of an optical sensor by judiciously setting it between the extreme values of the analog output of the light detector. This variable threshold compensates for changes in the analog output characteristics of the sensor and guarantees that a two-state condition is preserved in the digital logic output of the optical sensor.

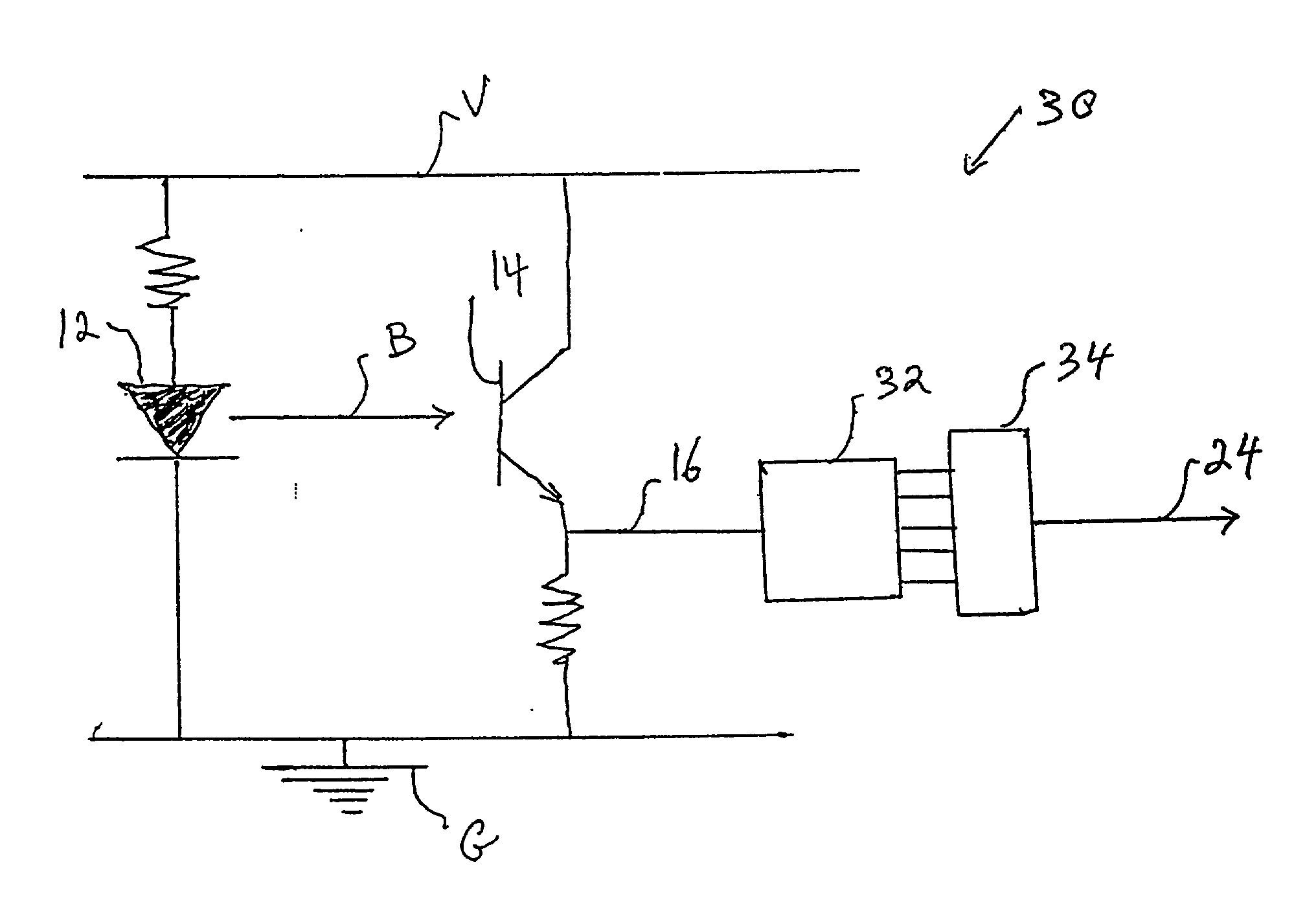

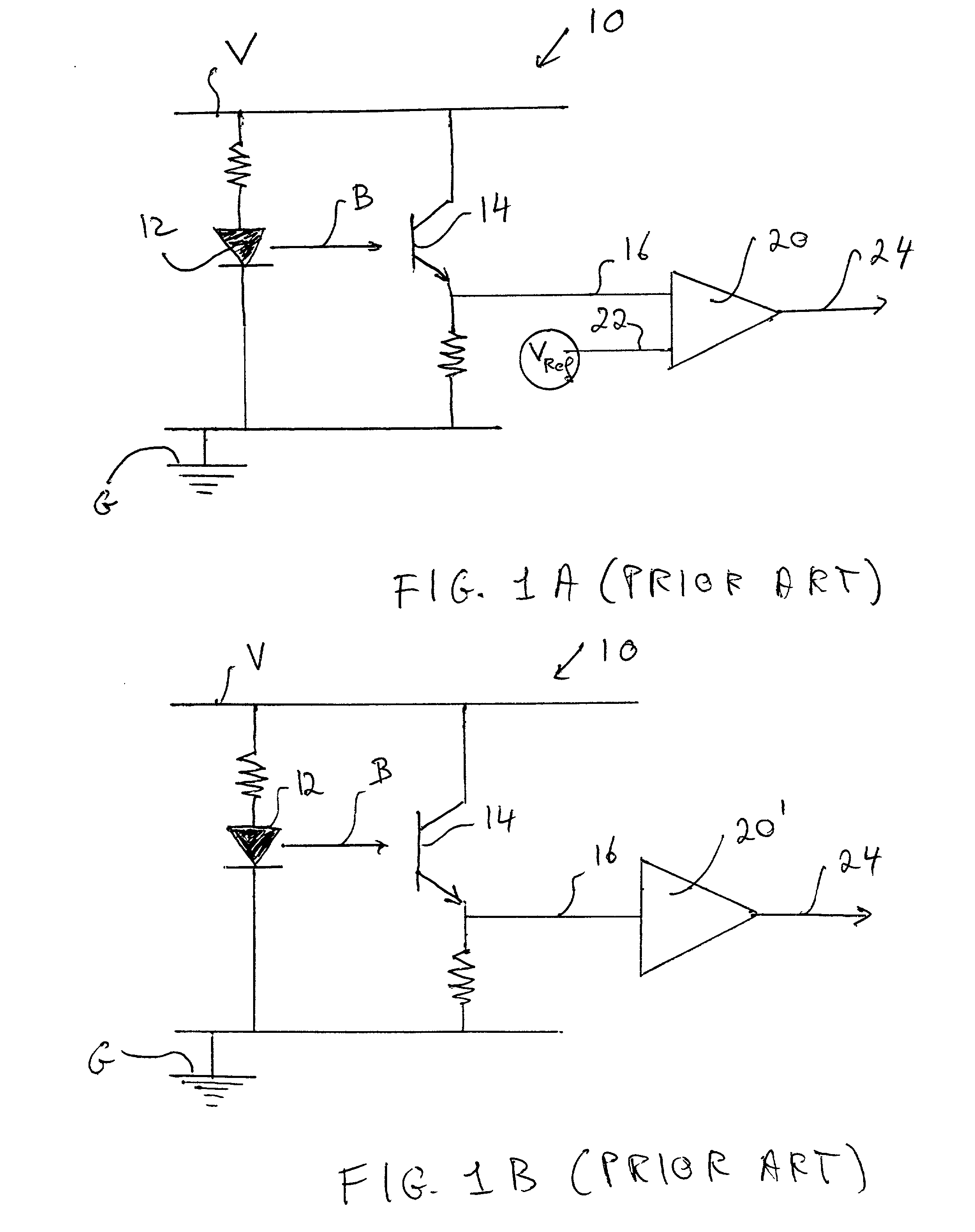

[0039] Referring to the drawings, wherein like parts are designated throughout with like numerals and symbols, FIG. 6 illustrates an ADC embodiment 30 of the invention, wherein the analog output 16 from the light detector 14 of an optical sensor is fed to an analog-to-digital converter 32 to produce a digital binary number that represents the magnitude of the analog signal 16 (voltage or current). This embodiment is preferably used in systems that include a microprocessor that contains the ADC function. Thus, the digital value of the light-detector signal produced by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com