Integrated turbine power generation system having low pressure supplemental catalytic reactor

a technology of integrated turbines and catalytic reactors, which is applied in the ignition of turbine/propulsion engines, engine starters, lighting and heating apparatus, etc., can solve the problems of limited efficiency of conventional integrated turbogenerator systems using flame-based or catalytic primary reactors, emissions problems, and failure to maintain a steady state operating temperatur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

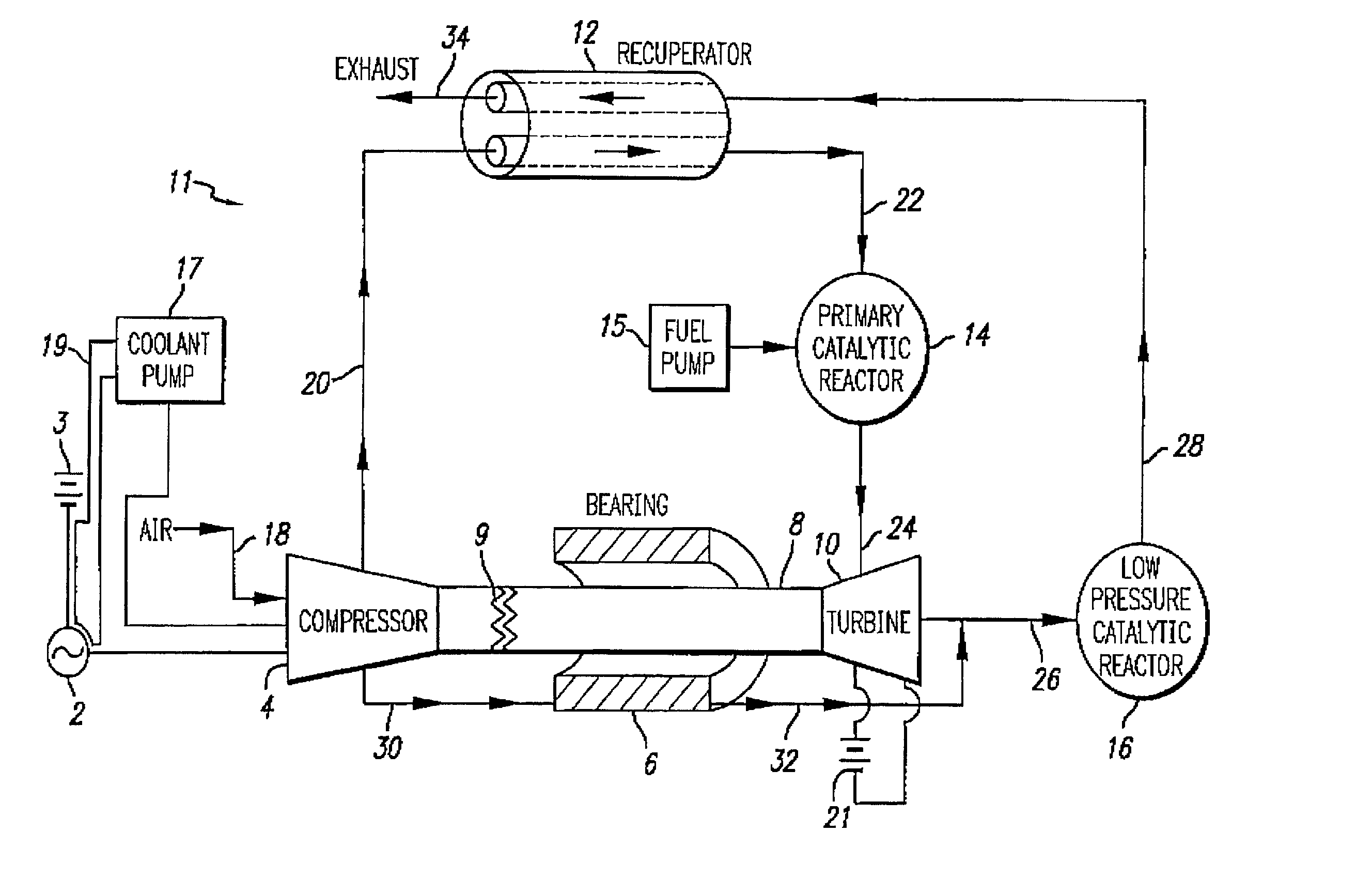

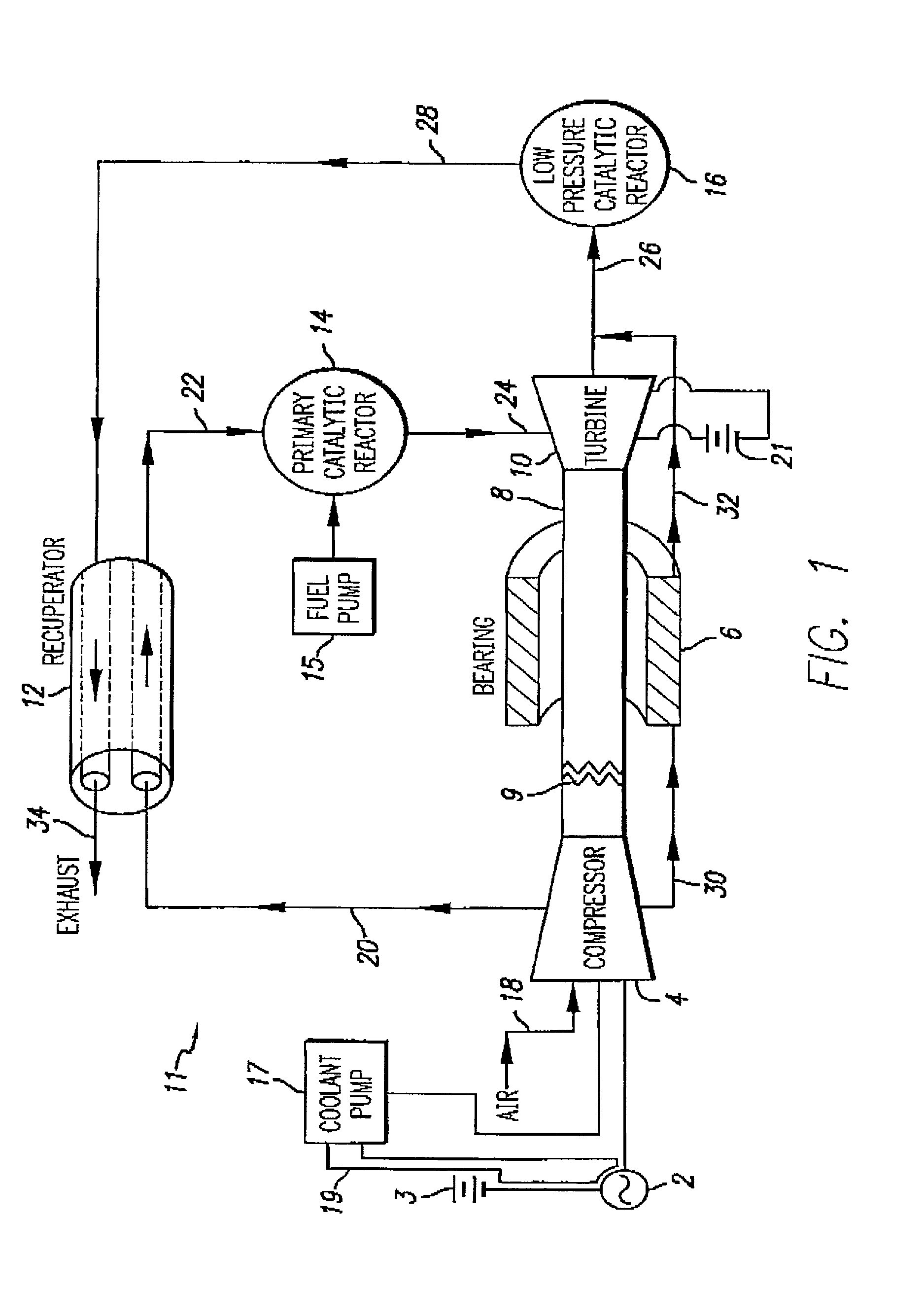

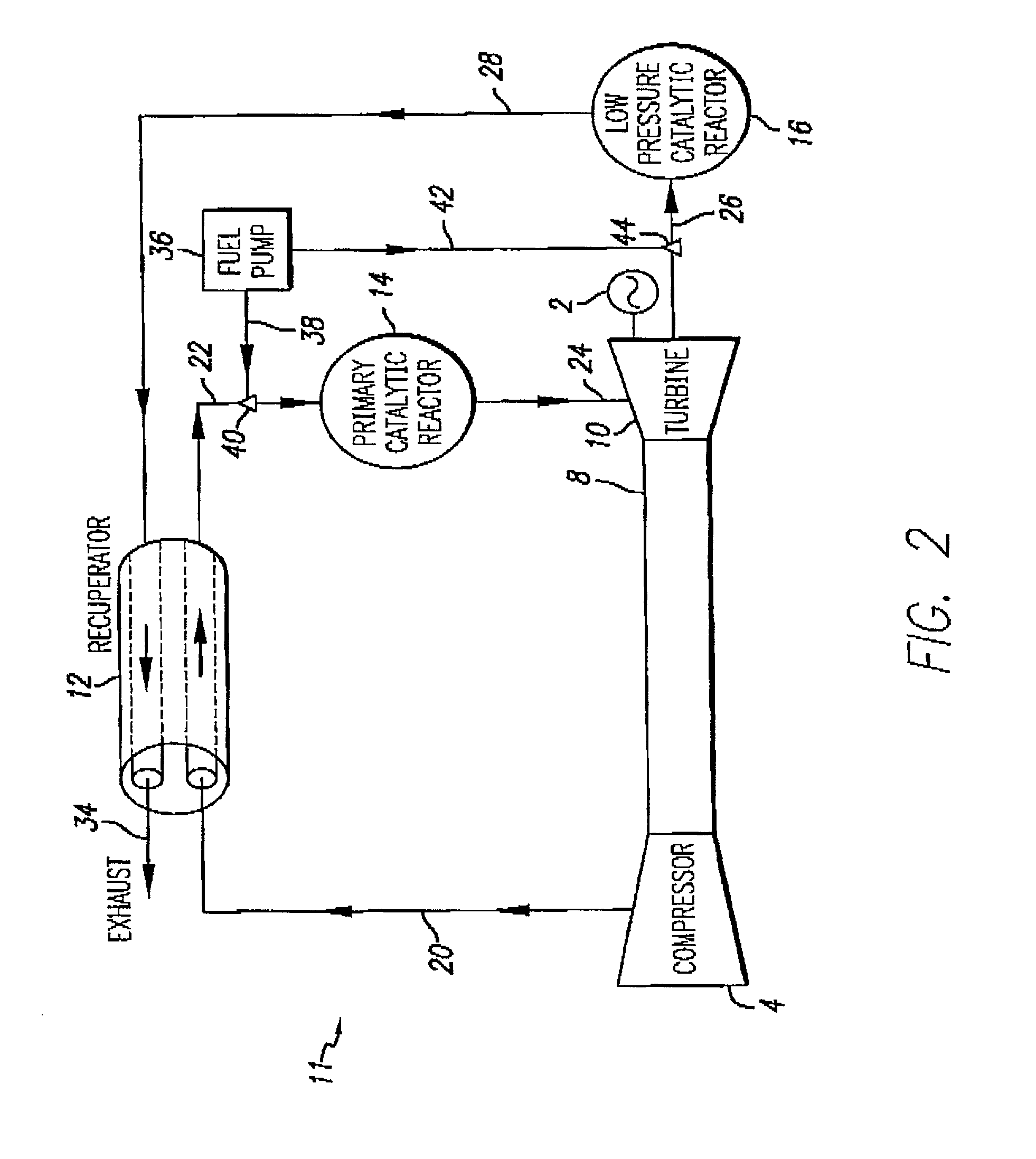

[0138] FIG. 1 illustrates a preferred integrated turbine power generation system in block diagram form. The system 11 is useful for many applications including cogeneration and as a power source for vehicles. System 11 preferably converts chemical energy, from fuels such as natural gas or gasoline, into mechanical power, electrical power and / or thermal energy. One preferred embodiment of system 11 includes a compressor 4 for compressing gas entering system 11 through line 18. The gas entering through line 18 can be air, or alternatively can be air mixed with fuel. Compressor 4 causes the gas to flow along line 20 to, and through, a heat exchanger, preferably a recuperator 12. As discussed in further detail below, the gas is heated during its passage through the recuperator 12, ideally by counter flowing heated exhaust gas that enters recuperator 12 along line 28 as the gas approaches its exit to system 11 through line 34. Once heated, the compressed gas flows onward along line 22 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com