Initiator assembly and gas generator using the same

a technology of gas generator and igniter, which is applied in the direction of electric fuzes, pedestrian/occupant safety arrangements, vehicular safety arrangements, etc., can solve the problems of high possibility of defective products being produced, increased manufacturing costs, and deterioration of priming (explosives)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

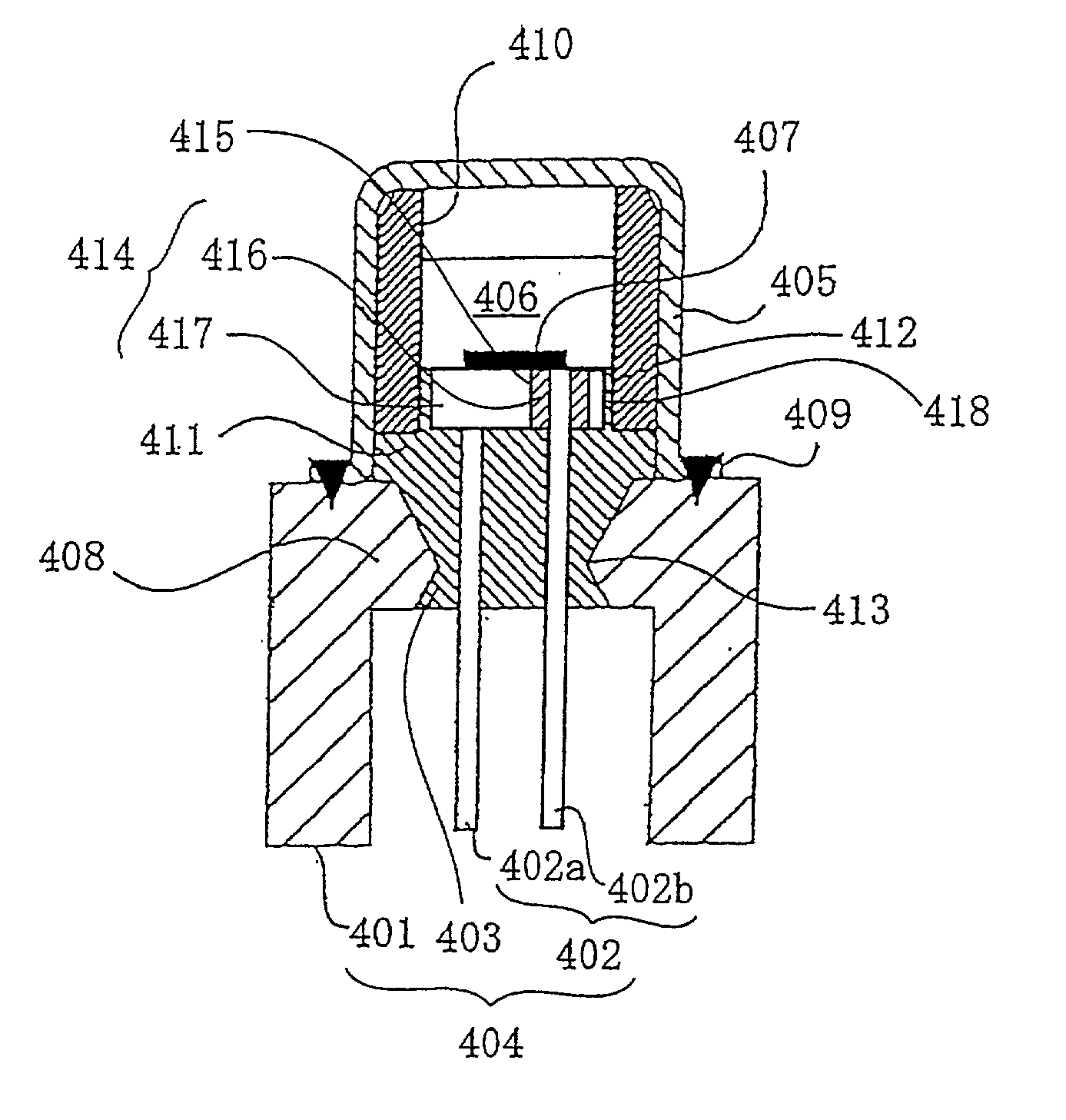

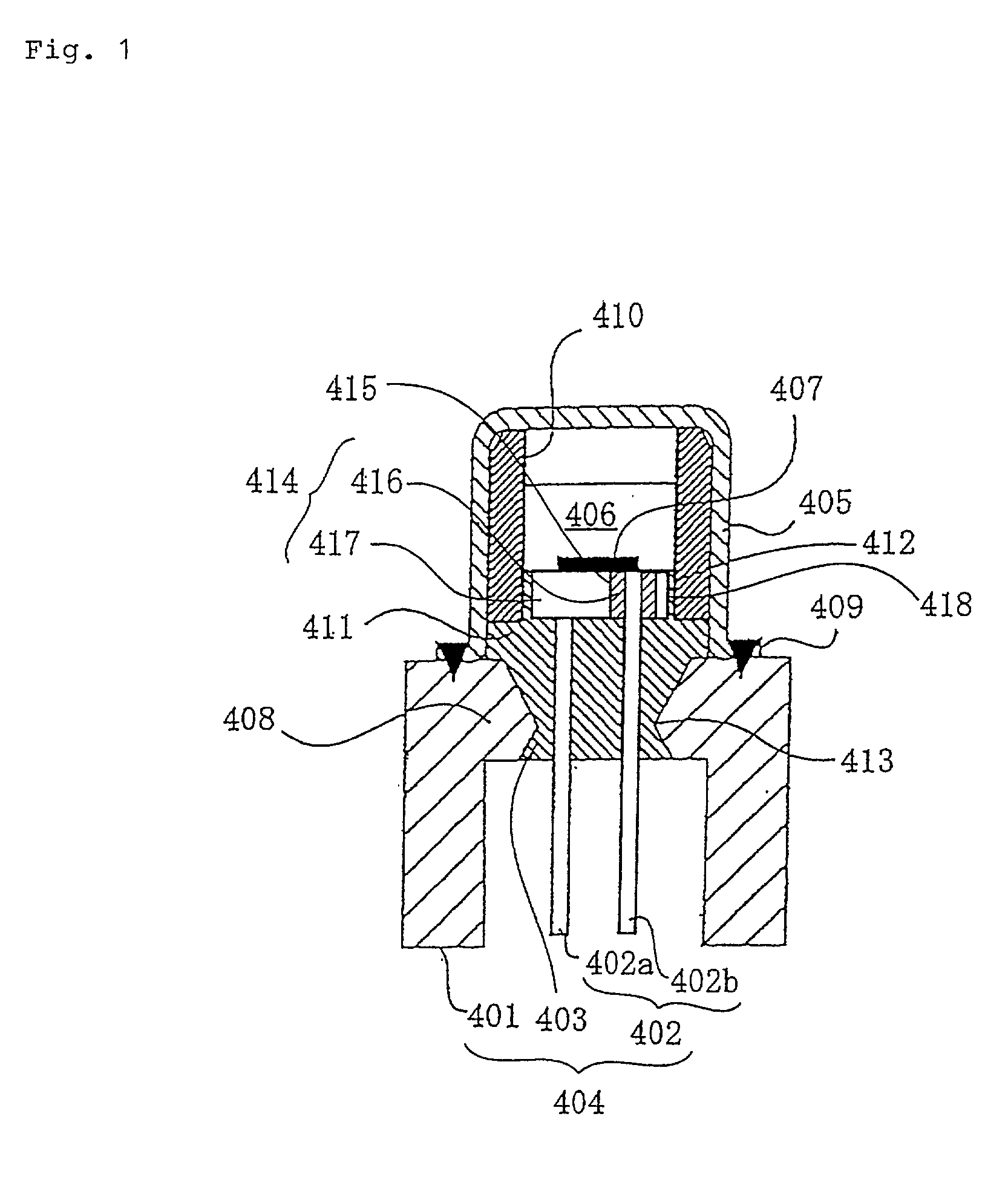

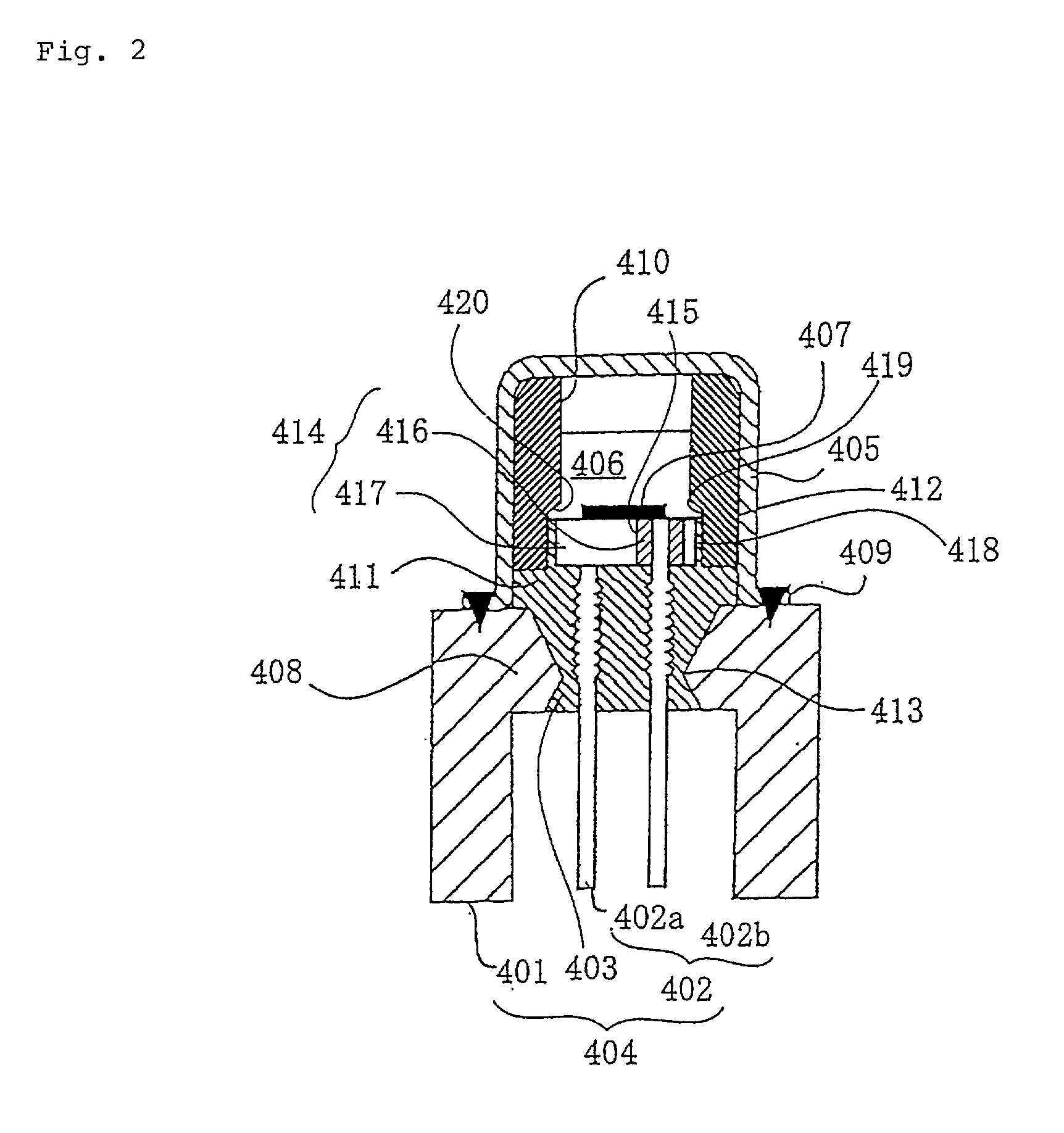

Image

Examples

embodiment 2

[0113] Embodiment 2

[0114] FIGS. 6 and 7 show an embodiment of a gas generator for an air bag formed by using the initiator assembly described above.

[0115] In the gas generator, a housing is formed by combining a diffuser shell 101 in which a gas discharge port 104 is formed and a closure shell 102 closing the diffuser shell, and the housing 103 includes an igniting means comprising the initiator assembly 100 and a gas generating means 105 to be ignited and burnt upon activation of the igniting means for generating a working gas to inflate an air bag (a bag body), and a filter means 106 for purifying and / or cooling the working gas generated by combustion of the gas generating means 105.

[0116] In the gas generator shown in FIG. 6, an inner cylindrical member 108 provided with a plurality of flame-transferring ports 107 on a circumferential wall is arranged in the center inside the housing, a space 109 for storing the igniting means is formed inside the inner cylindrical member 108, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com