Gas-barrier film and sealed object

A technology of gas barrier property and gas barrier layer, which is applied in the direction of electrical components, electric solid devices, semiconductor devices, etc., can solve the problems of performance degradation and achieve excellent sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0141] The amount of the solvent used in the preparation of the adhesive composition may be used such that the solid content concentration is preferably 8 to 48 mass%, more preferably 8 to 38 mass%, and still more preferably 8 to 28 mass%.

[0142] (other ingredients)

[0143] In the range that does not impair the curing of the present invention, in addition to the above-mentioned polyolefin resin (A), the above-mentioned thermosetting component (B), the above-mentioned curing catalyst (C), the above-mentioned silane coupling agent (D), the above-mentioned In addition to the solvent, the adhesive composition may further contain other components. Examples of other components include ultraviolet absorbers, antistatic agents, light stabilizers, antioxidants, resin stabilizers, fillers, pigments, extenders, softeners, thickeners, and the like.

[0144] [Base layer]

[0145] By having the underlayer in the gas barrier film of the present invention, the release sheet can be effect...

Embodiment 1

[0337] [Production of gas barrier film]

[0338] (1) Formation process of base layer

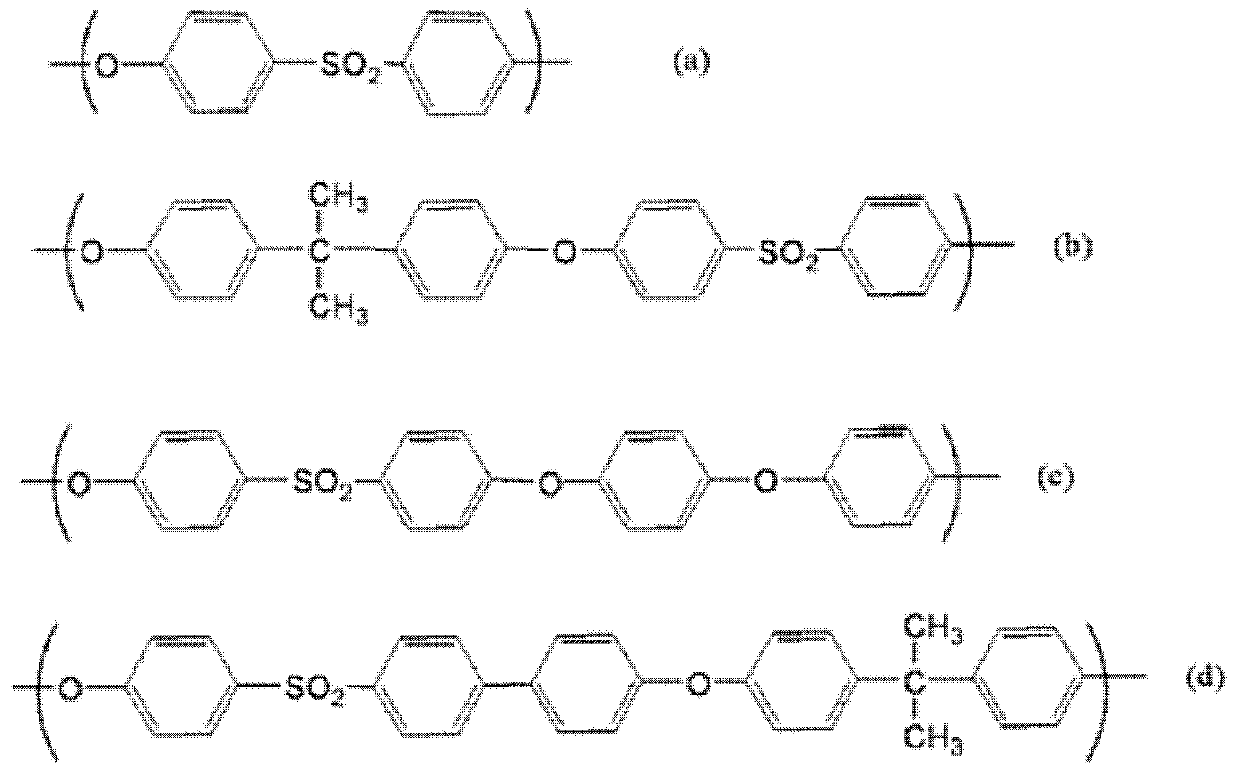

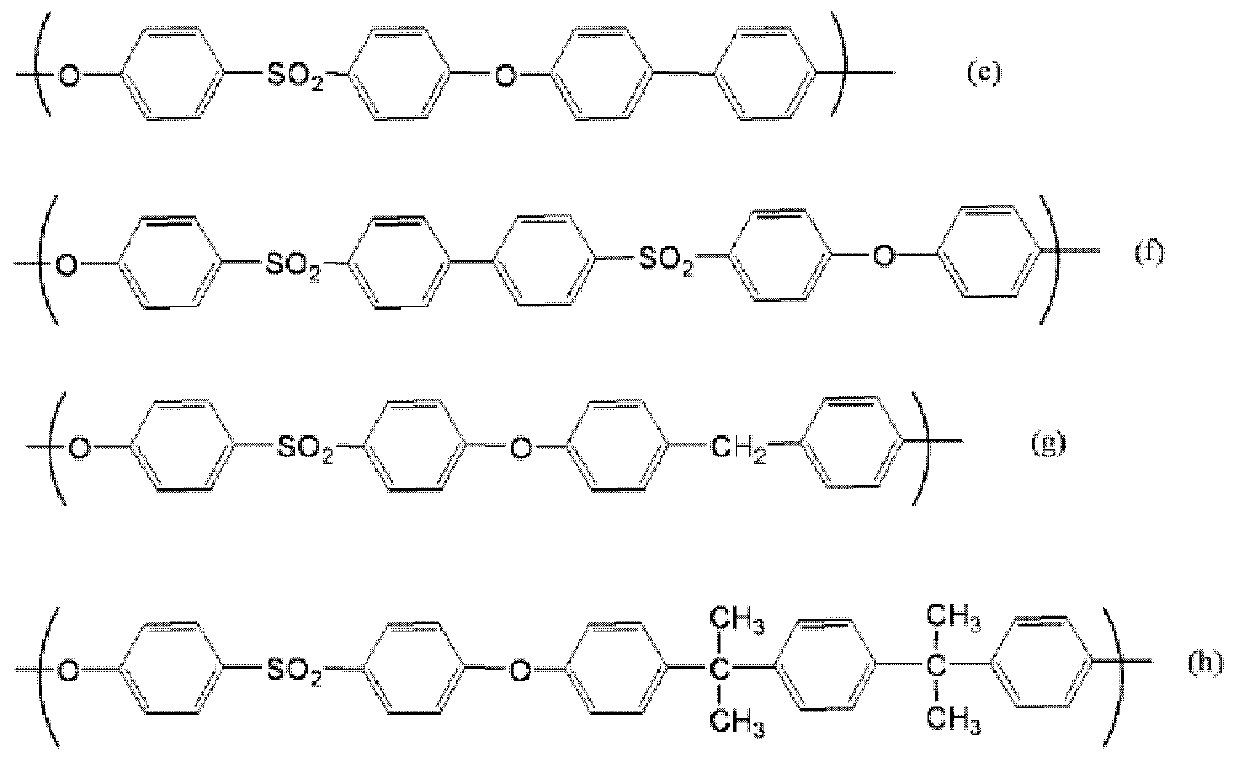

[0339] As a thermoplastic resin, 60 parts of polysulfone-based resin (PSF) pellets (manufactured by BASF Corporation, "ULTRASON S3010", Tg=180° C.) were dissolved in methylene chloride to prepare a 15% solution of PSF.

[0340] To this solution were added 40 parts of tricyclosilane dimethanol diacrylate (manufactured by Shin-Nakamura Chemical Industry Co., Ltd., ADCP) as an energy ray curable component, and bis(2,4,6-trimethylmethacrylate) as a polymerization initiator. 1 part of benzoyl)phenylphosphine oxide (manufactured by BASF, "Irgacure 819") was mixed to prepare a composition for a base layer.

[0341]As the first release sheet, apply by die coating on the non-treated surface of the easy-adhesive-treated polyethylene terephthalate (PET) film (manufactured by Toyobo Co., Ltd., "PET50A-4100", thickness 50 μm) The composition for the base layer prepared above was spread to form a coatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com