Structures for edge treatment and for decoration of counters and panels, and for the assembly thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

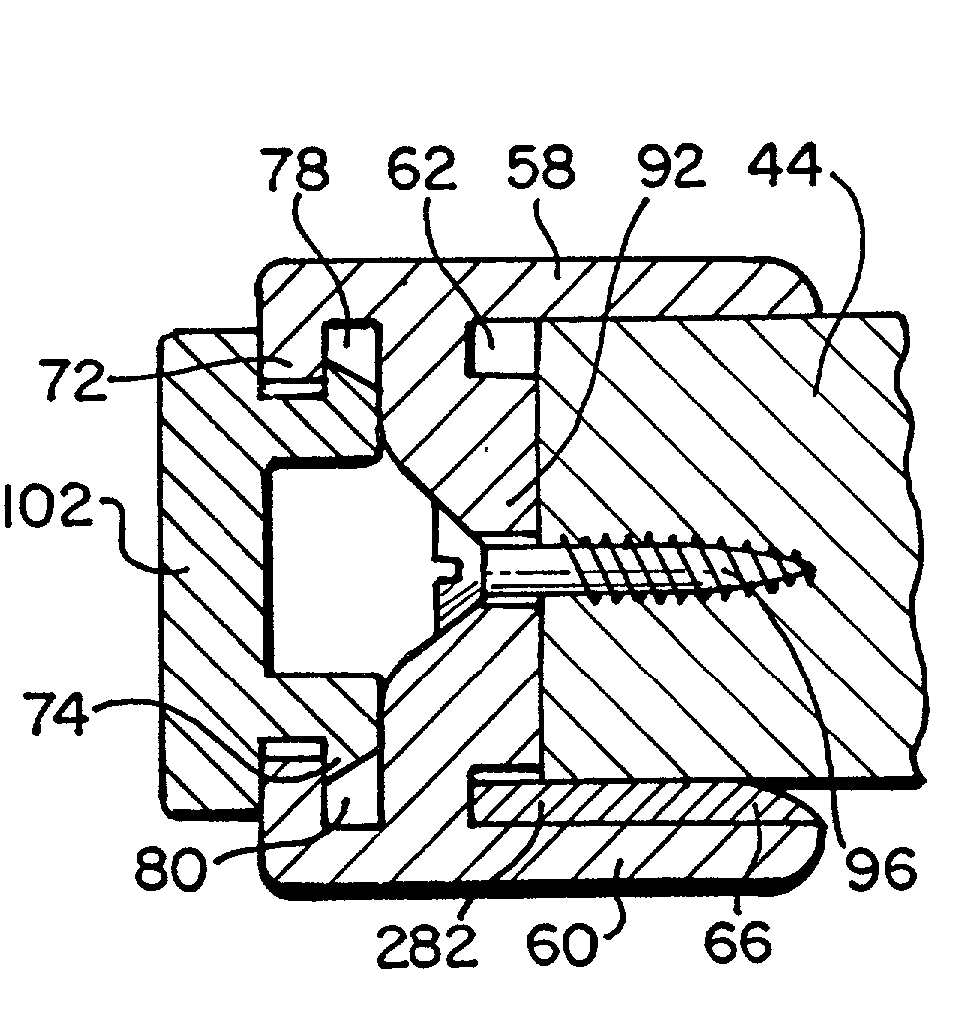

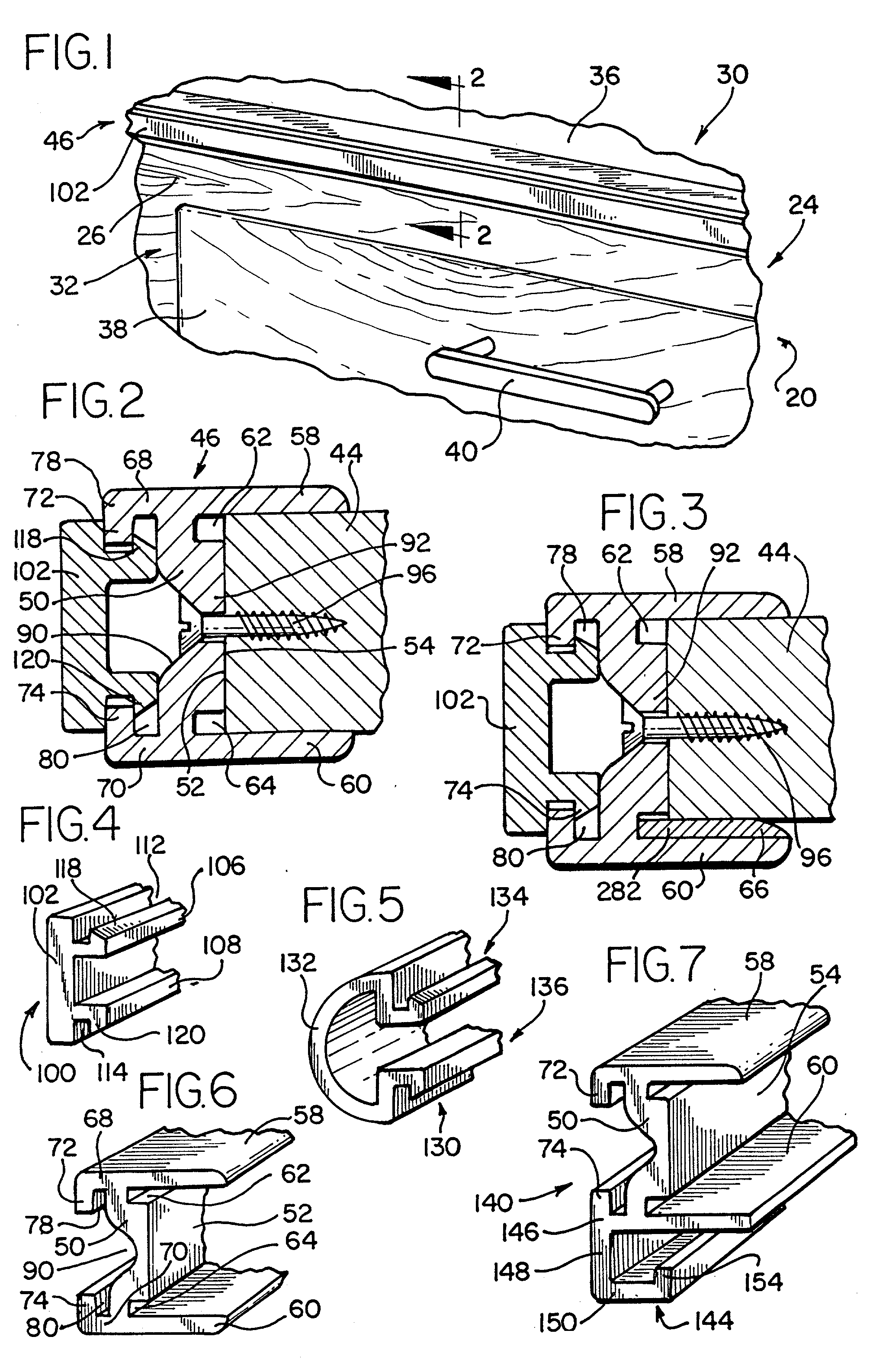

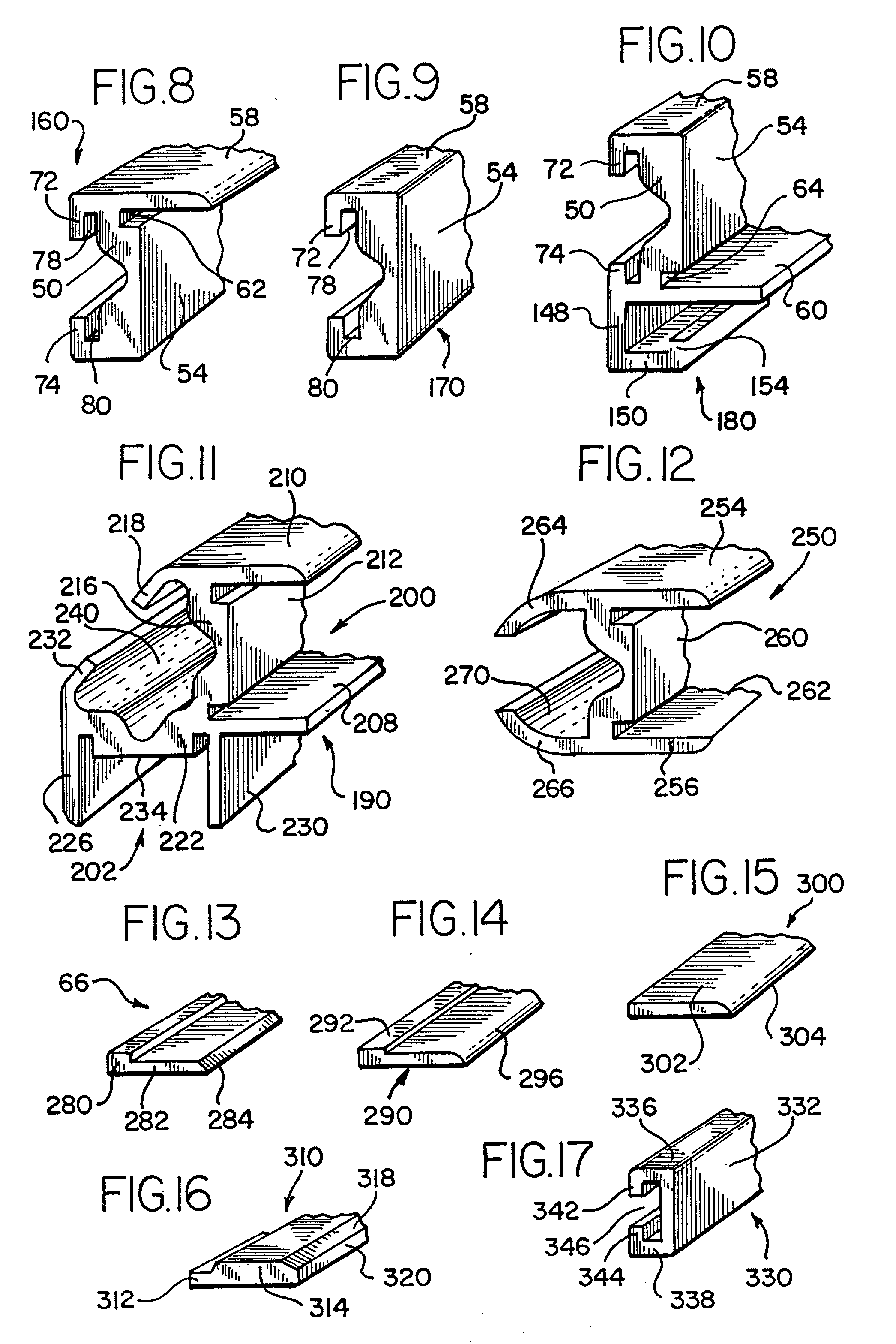

[0035] The aims, objects and advantages of the invention are achieved by providing a family of principal extrusions, preferably fabricated as extruded aluminum, aluminum alloys and other metals and their alloys. In one principal embodiment of the invention channel-defining selectable extrusions are secured in tensioned and firmly gripping engagement with outwardly extending edge or end structures of a counter top, table, cabinet or the like, to cover at least the end faces thereof. In some embodiments of the invention screws may be used for effecting even more positive securement of the elongate extrusion to the edge of the supporting countertop, table, cabinet, or other structure.

[0036] In other preferred embodiments of the invention secondary extruded components coextensive lineally with the primary extrusion, are employed to cover and to shield visually any auxiliary mechanical elements such as screws used to provide enhanced securement of the principal extrusion to its supportin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com