Shouldered ramp for streetwork cover and method of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Turning now to the drawings, the invention will be described in a preferred embodiment by reference to the numerals of the drawing figures wherein like numbers indicate like parts.

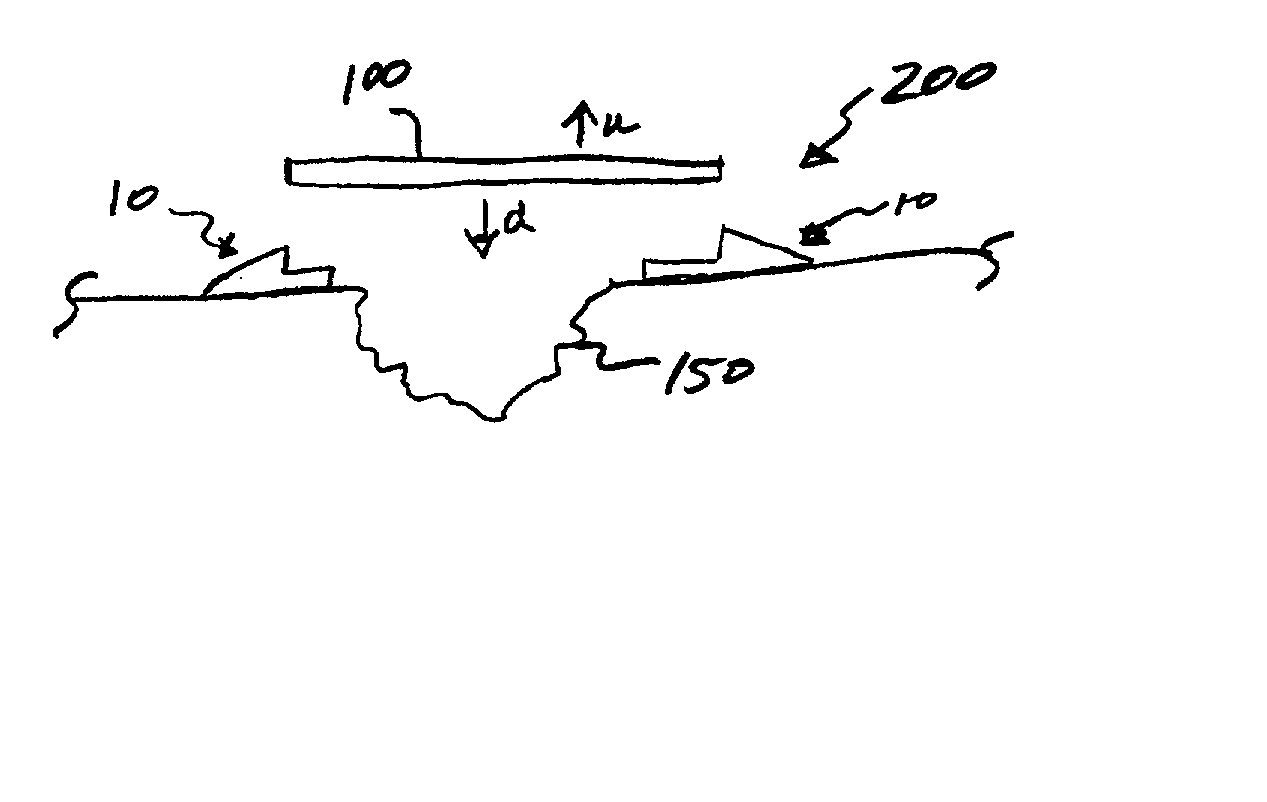

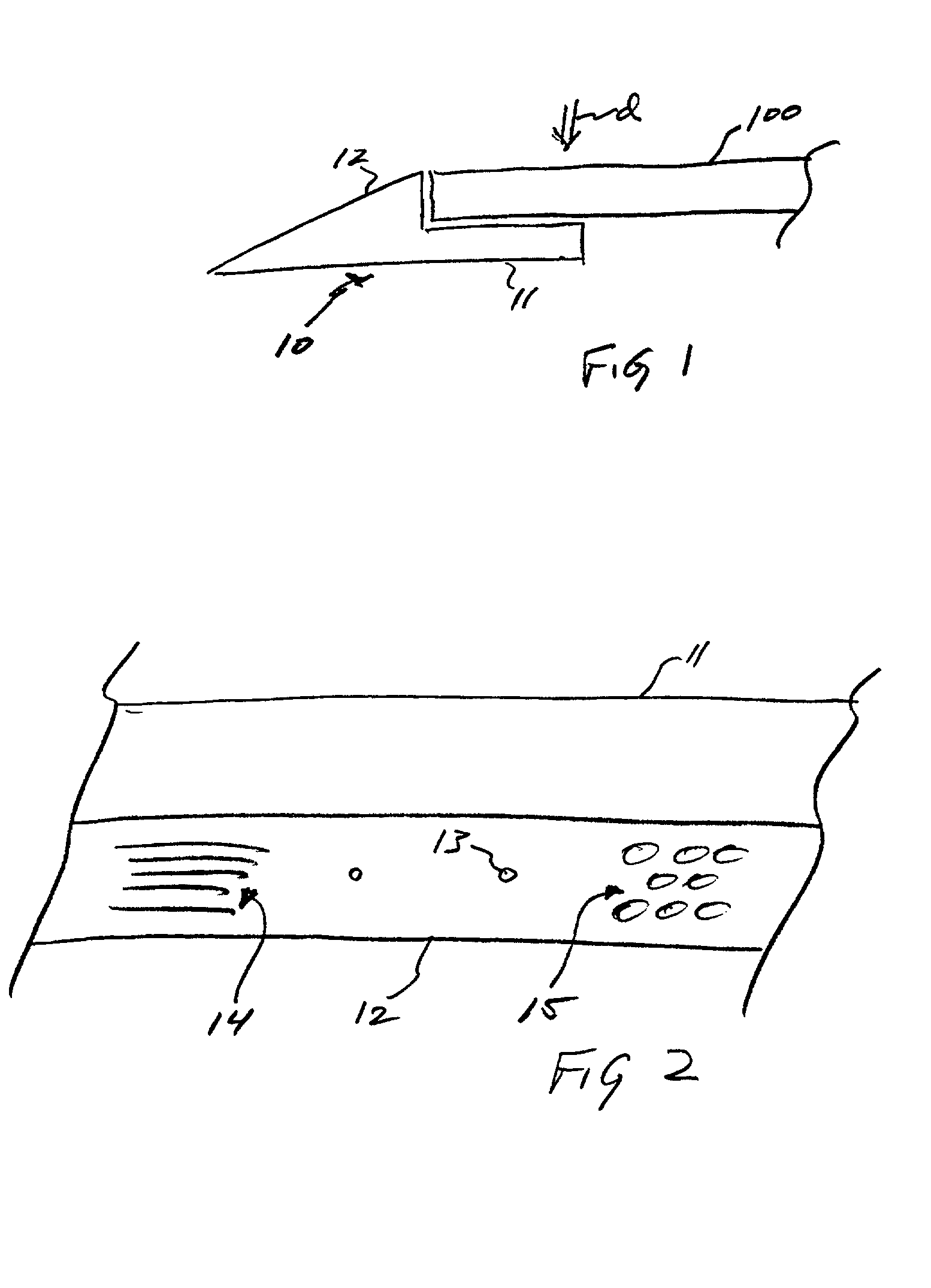

[0040] FIG. 1 is a side elevation of ramp strip 10 with plate 100 lowered in direction of arrow d down onto shoulder (or bed) 11 of strip 10.

[0041] FIG. 2 is a partial plan view of ramp strip 10 (without plate 100), illustrating preferred layout of shoulder 11 and ramp 12. Optional anchor apertures 13 and optional traction features such as grooves 14 and holes or dimples 15 are shown.

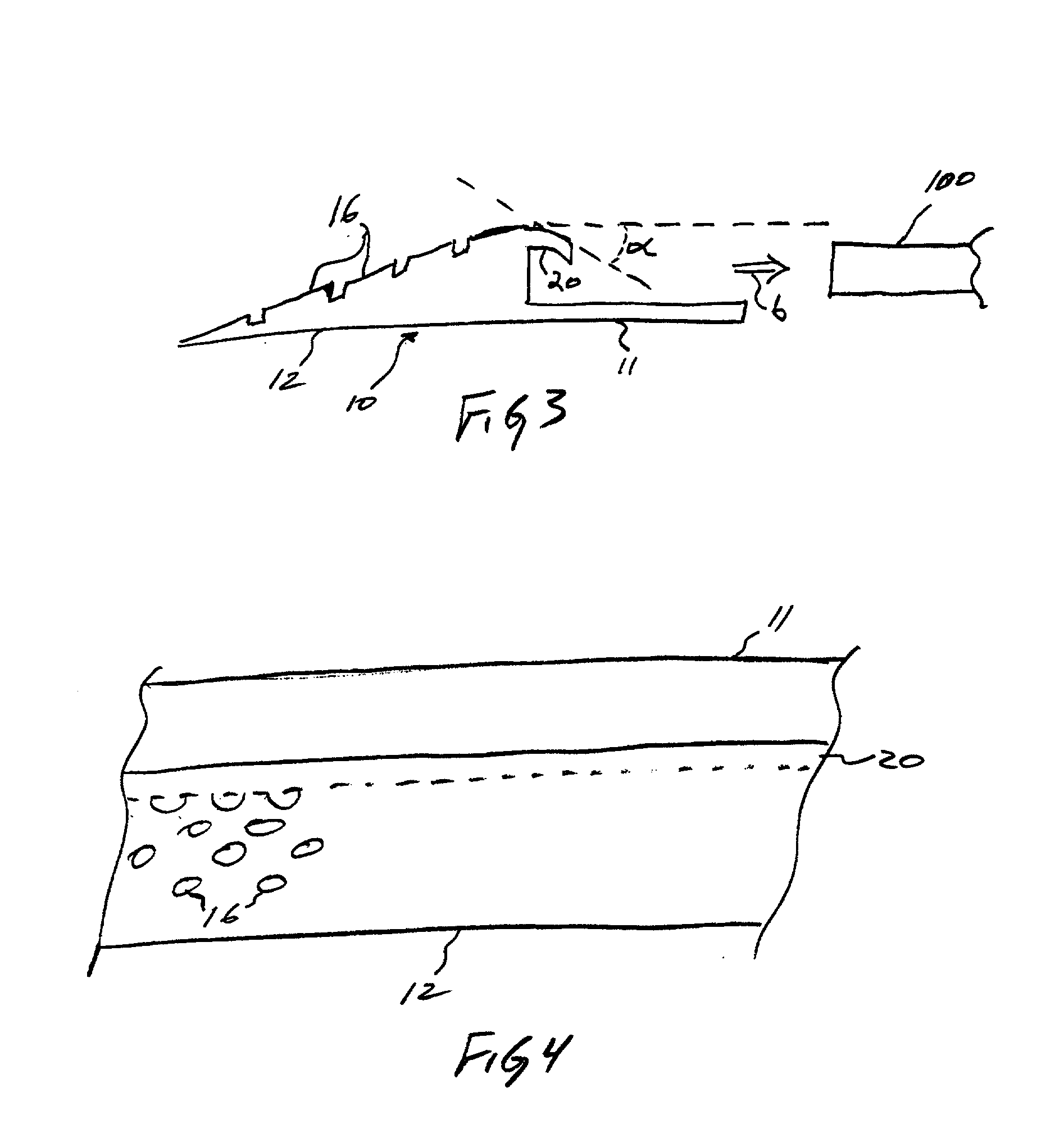

[0042] FIGS. 3 and 4 illustrate an preferred embodiment of ramp strip 10 where ramp 12 has preferred traction features in the form of raised buttons 16 and a depending spring lip 20 depending toward shoulder 11 at angle .alpha.. Ramp strip 10 is moved into engagement with plate 100 in the direction of arrow b. In effecting the engagement, lip 20 is generally displaced and forced upwardly from its resting or unsprung pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com