Geometric toy construction system

a construction system and geometric model technology, applied in the field of educational toy geometric models, can solve the problems of limited learning opportunities, system flexibility, and limited learning opportunities, and achieve the effects of limiting the variety of models that can be created

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

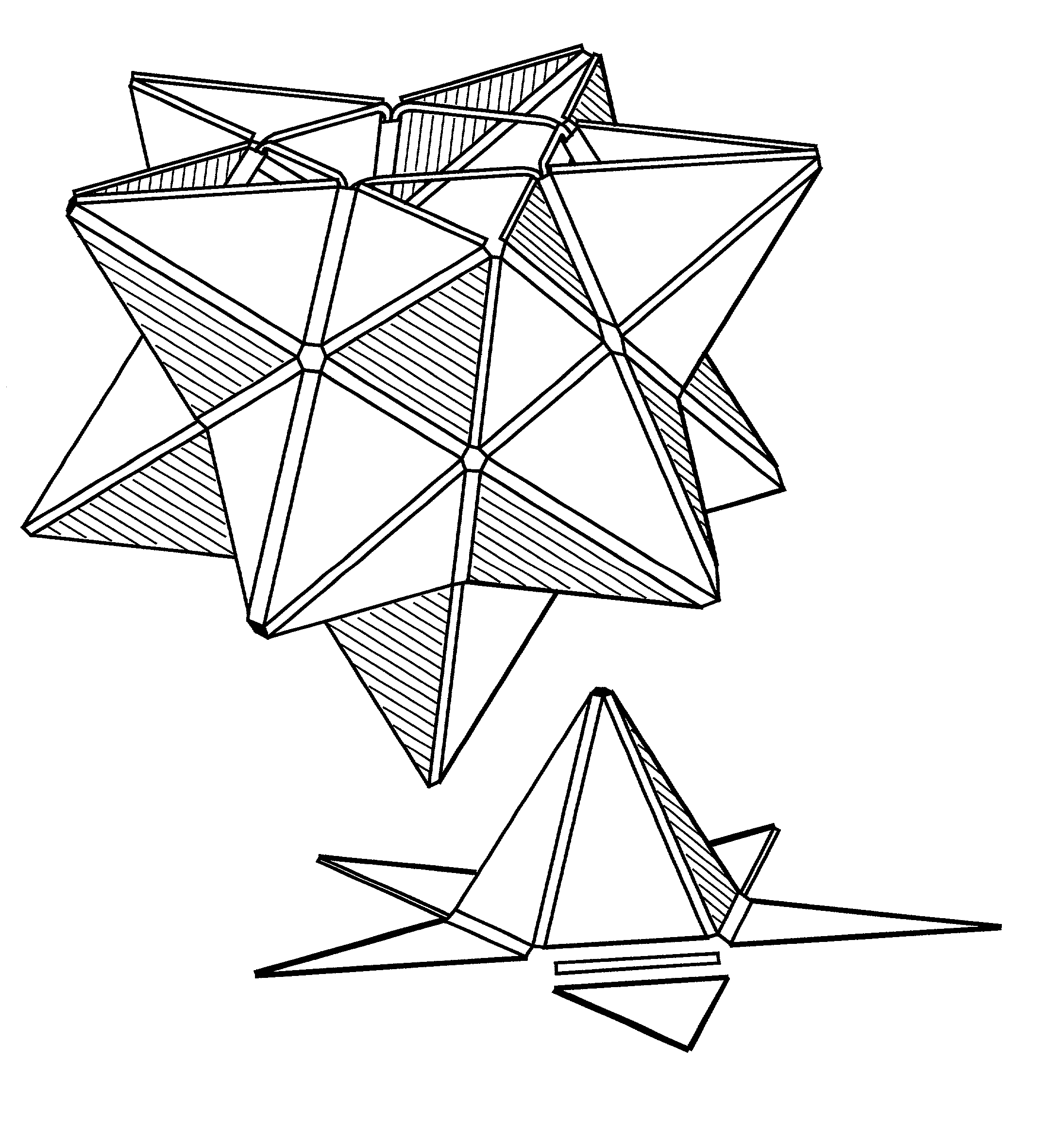

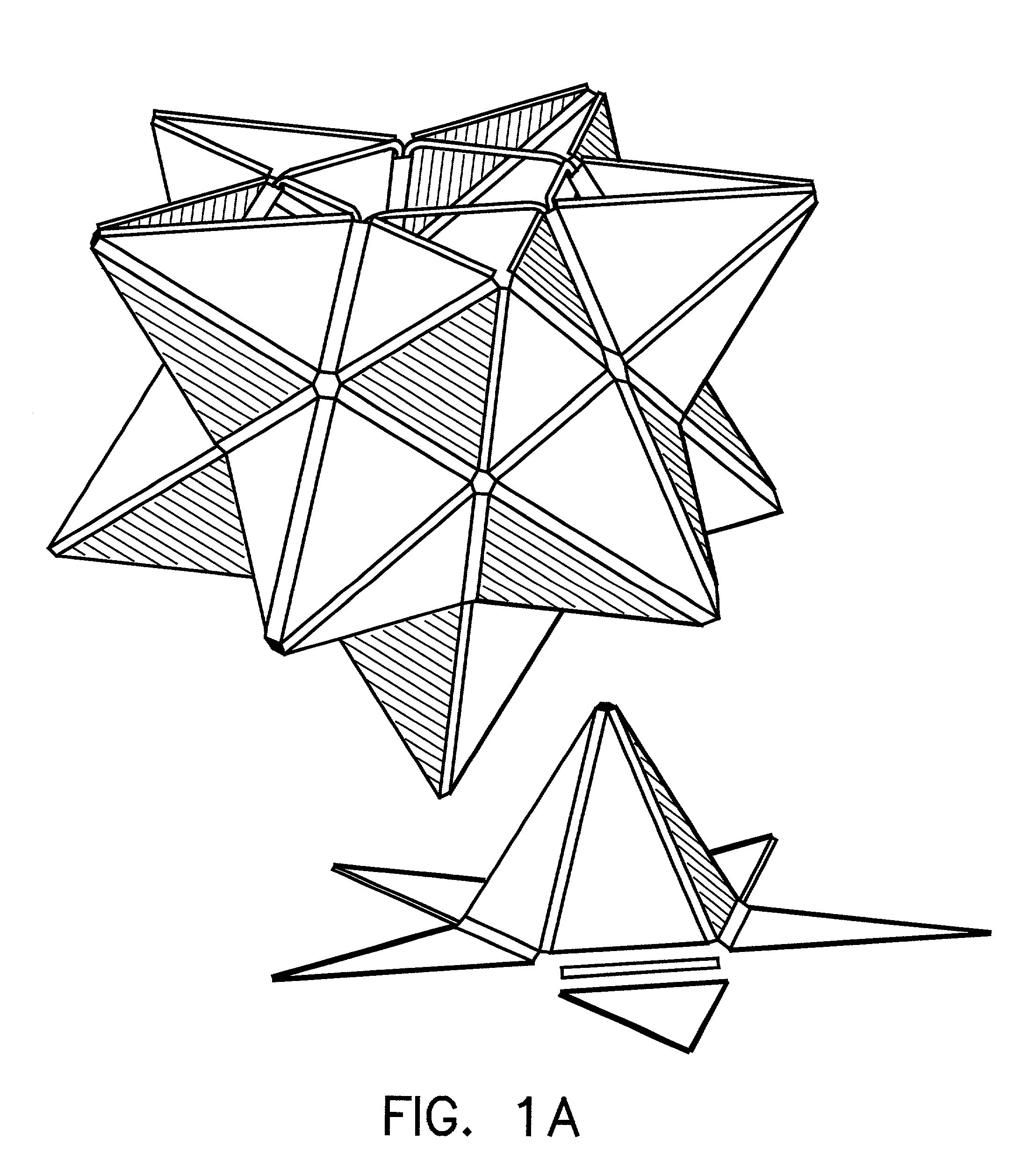

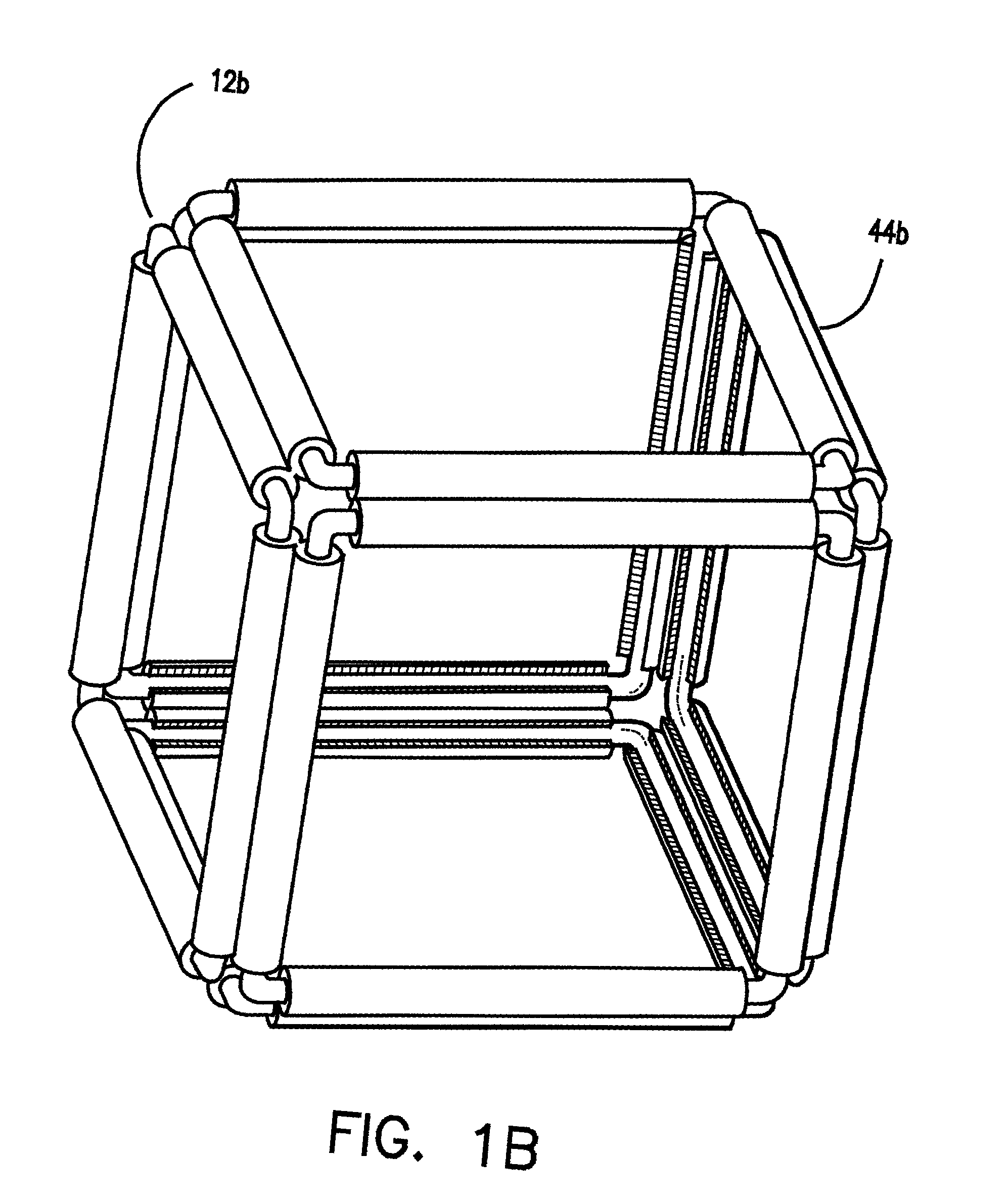

[0050] A preferred embodiment of the geometric model construction system is comprised of of a variety of shape elements and connector strips. Examples of shape elements are illustrated in FIGS. 2A to 2D. Connector strips of two styles are shown in FIGS. 3A and 3E. These two types of parts (the shape elements, and the connector strips) comprise the basis of the geometric toy construction system. From these parts two and three-dimensional geometric toy models are built up as shown in FIGS. 1A and 1B. FIG. 1A shows a partly completed model of the small stellated dodecahedron. FIG. 1B shows a fully completed model of a cube. Each shape element in the cube is comprised of an identical open wire frame square, one of these is wire frame element 12b. The edges of adjacent shape elements are held together by twelve identical connector strips. One of these is female double connector strip 44b. They have c-shaped hinge-pivots designed to admit and grip the wire frames. Alternatively shape elem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com