Fireproof repository

a fireproof container and repository technology, applied in the field of fireproof containers, can solve the problem of not being able to obtain a sufficiently acceptable fireproof container, and achieve the effect of preventing the quality deterioration of storing articles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Fireproof Container and its Fireproof Ability

example 1-1

Fireproof Container

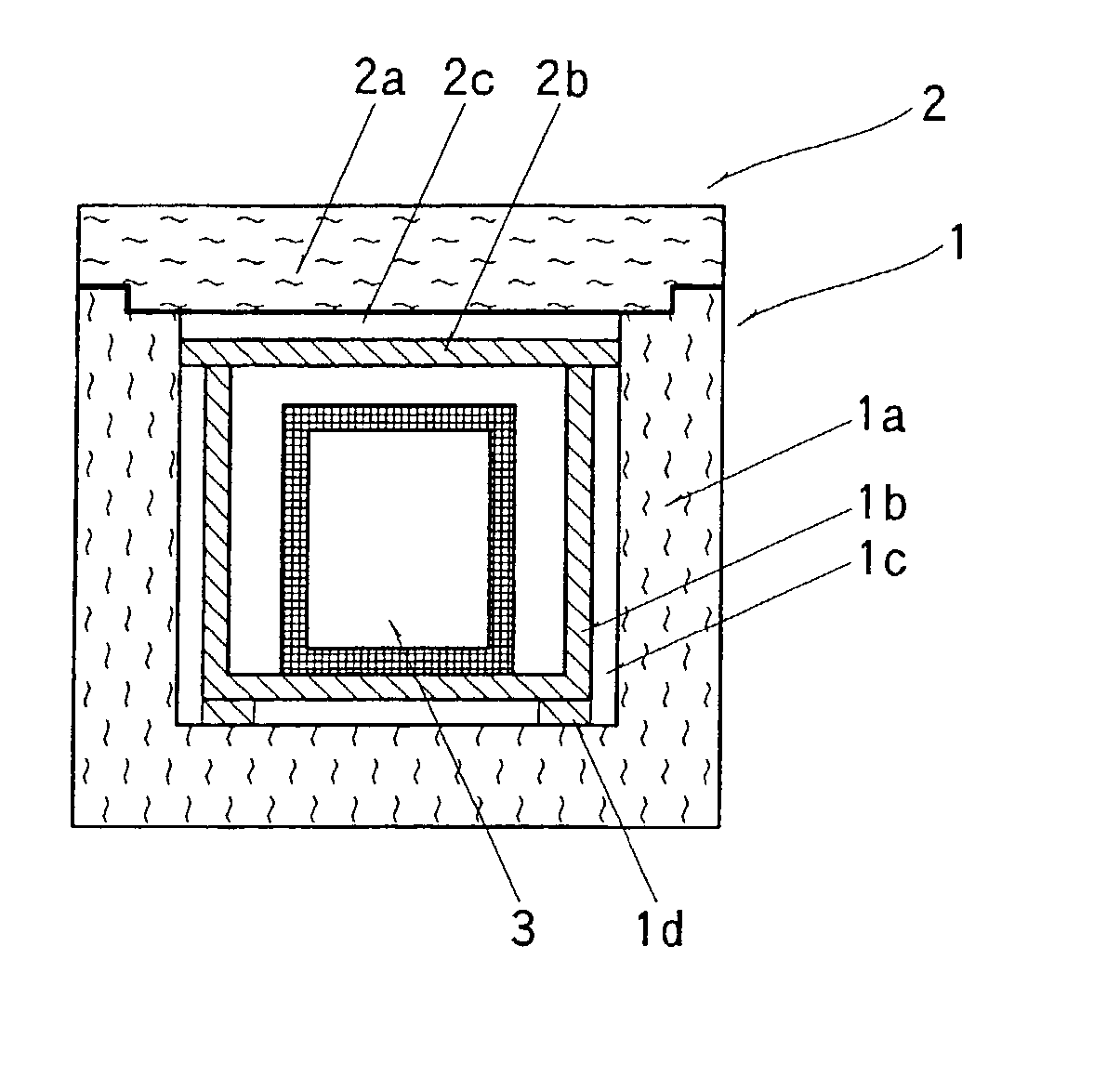

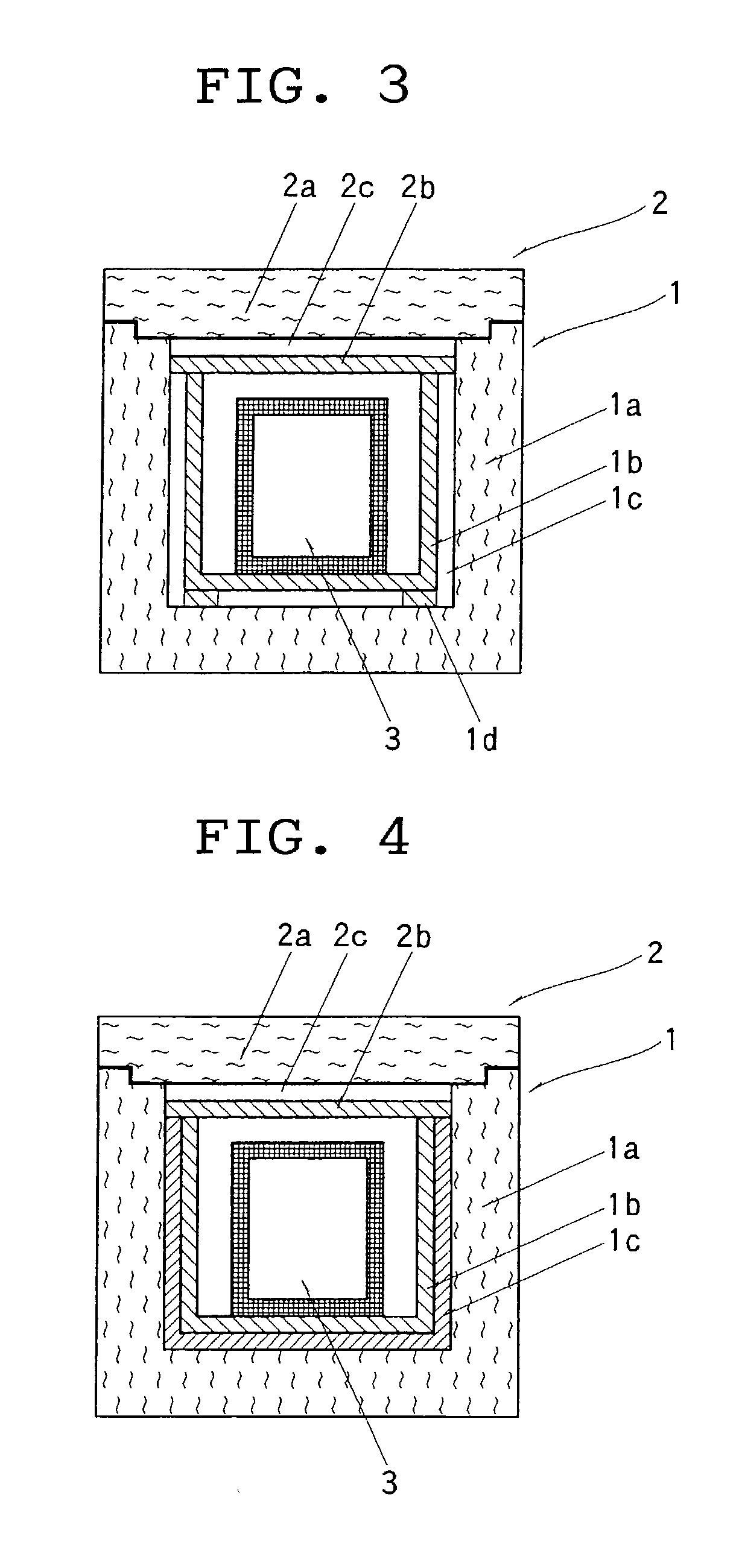

[0040] As an embodiment of the fireproof container of the present invention, a fireproof container A, having the structure shown in typically with its longitudinal sectional view of FIG. 3, was prepared. As shown in FIG. 3, in a container portion 1 in the fireproof container A, an outer layer 1a is a layer, having 100 mm in thickness, made of "ISOWOOL.RTM. 1260 BOARD", a ceramic fire board as a fireproof insulation material commercialized by Isolite Insulating Products Co., Ltd., Tokyo, Japan; an inner layer 1b is a layer having 10 mm in thickness made of "ISOLITE C-1", an insulating firebrick as an incombustible material commercialized by Isolite Insulating Products Co., Ltd., Tokyo, Japan; and a middle layer 1c is an air layer, having 10 mm in thickness, provided via a spacer 1d made of the above insulating firebrick. A lid means 2 is composed of an inner lid, comprising a layer 2b having 10 mm in thickness, which is made of the above insulating firebrick corres...

example 1-2

Standard Heat Test

[0044] The fireproof containers A, B and C in the above example and the containers X.sub.1 and X.sub.2 as controls were subjected to the 1-hour standard heat test specified in "JIS Fire-resistive container(s)" to examine the inner temperature change of their container portions. The results are in FIG. 6. In FIG. 6, the curves A, B and C are respectively the inner temperature changes for the fireproof containers A, B and C; and the curves X.sub.1 and X.sub.2 are respectively those for the container portions X.sub.1 and X.sub.2. In this test, a box of Paulownia wood as a model of storing article was placed in each container portion and, after completion of the test, the condition of the boxes were macroscopically observed.

[0045] As shown in FIG. 6, the peak of inner temperature of the fireproof container A was about 160.degree. C., and those of the fireproof containers B and C were respectively about 130.degree. C. and about 120.degree. C. With regard to the conditio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com