Drain garbage collector

a garbage collector and drain technology, applied in the direction of sewage draining, sewer cleaning, chemistry apparatus and processes, etc., can solve the problem of not being able to effectively filter flowing garbage in the drain itself, and achieve the effect of preventing inundation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Wherever possible in the following description, like reference numerals will refer to like elements and parts unless otherwise illustrated.

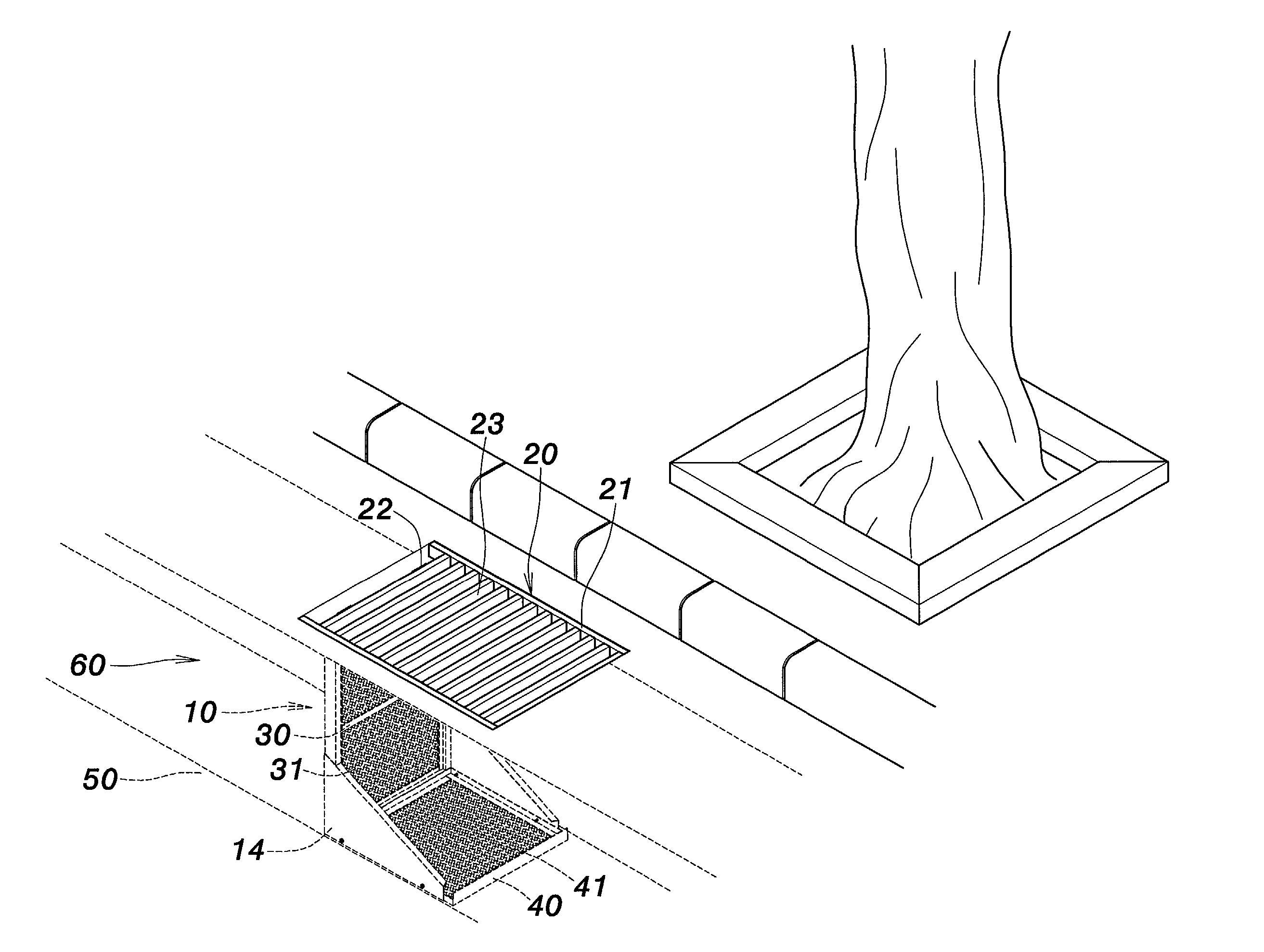

[0018] Referring to FIG. 3 through FIG. 8, various schematic views illustrate a drain garbage collector according to an embodiment of the present invention. The garbage collector comprises a frame 10, a top grate 20, a separator grate 30, and a collector grate 40. The frame 10 is L-shaped and made of metallic materials. First pivot connecting structures 11 are placed on the rear side edge of the frame 10 to connect the top grate 20 coaxially via pivot axles 12. The top grate 20 is made of metallic materials also, and is constituted of a plurality of bars 21 that are spaced apart from one another so as to define a plurality of passages 23 there between. The bars 21 may form the top grate 20 via various methods such as soldering, hard soldering, ultra-sonic welding, or resistive welding, etc.

[0019] Second pivot connecting structures 22, corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com