Water soluble sheet material

a sheet material and water-soluble technology, applied in the field of water-soluble sheet material, can solve the problems of people often inadvertently discard cigarettes, and more particularly the filters of cigarettes, and reducing the amount of paper in the environmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

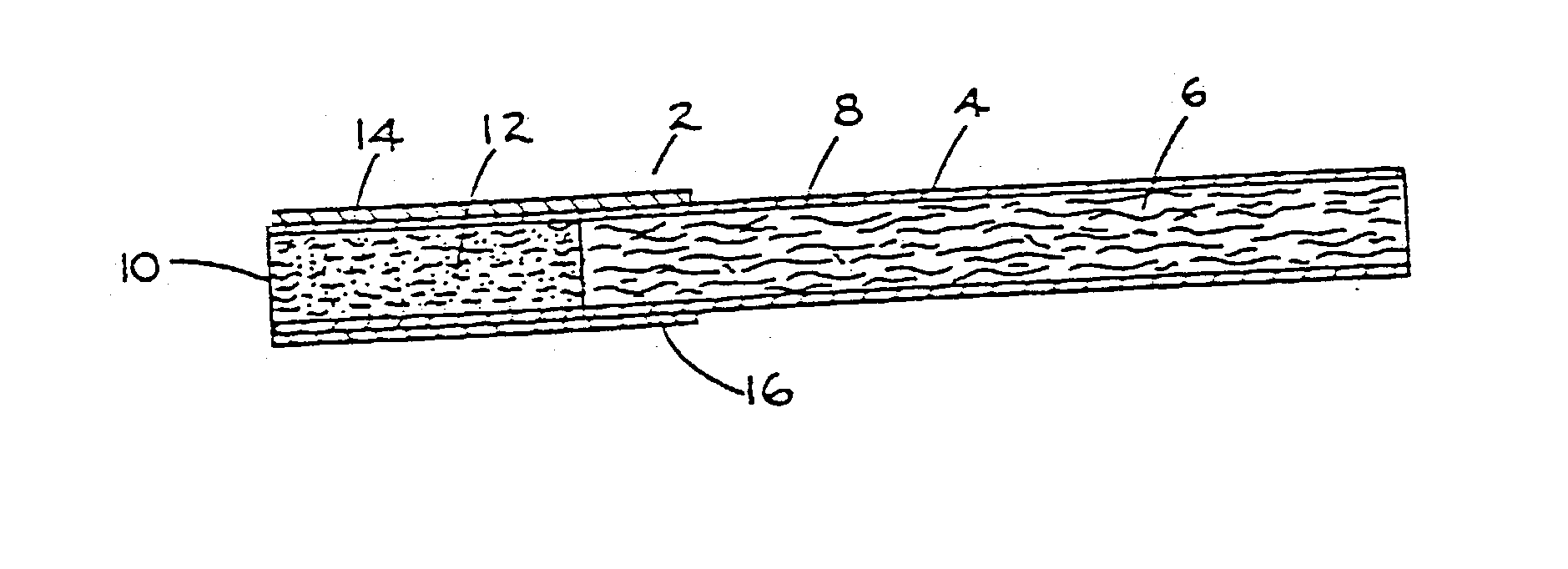

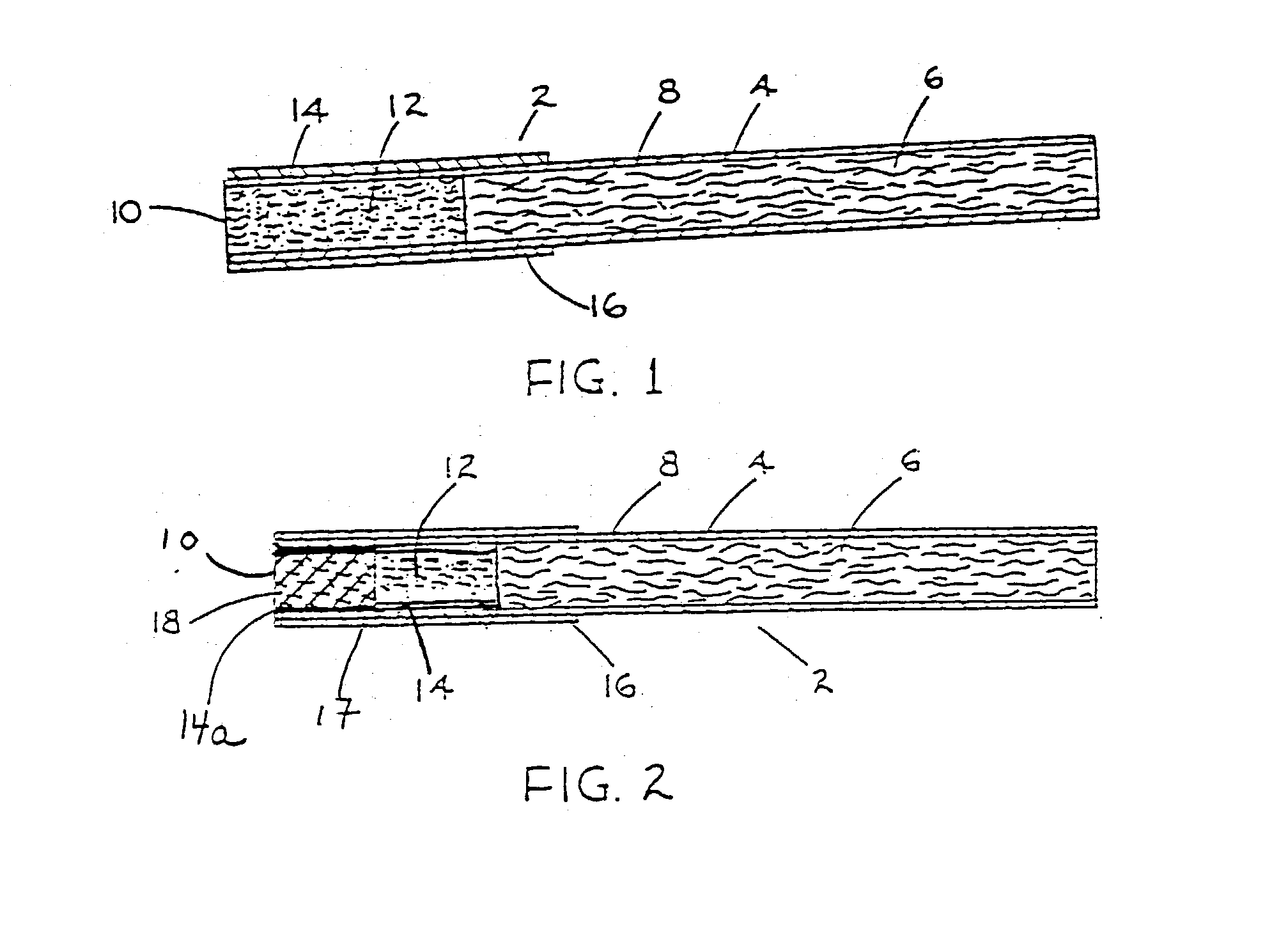

Image

Examples

example 1

[0022] The slurry had the following composition:

1 Component % Solids Basis NaCMC.sup.1 33.52 guar gum 22.35 glycerin 5.03 wood pulp 39.11

[0023] The slurry was cast at a slit width of 26.5 mm and a casting speed of 50 ft / min. The plug wrap material had a yellow color, a smooth texture and good strength. The plug wrap material dispersed in water in about 10 minutes.

example 2

[0024] Example 2 was similar to Example 1 except additional wood pulp on a percent solids on a basis was used.

2 Component % Solids Basis NaCMC 21.51 guar gum 14.34 glycerin 5.02 wood pulp 59.14

[0025] The slurry was cast at a slit width of 26.5 mm and a casting speed of 50 ft / min. The plug wrap material had a yellow color, a smooth texture and good strength. The plug wrap material dispersed in water in about 25 minutes.

example 3

[0026] Example 3 is similar to Examples 1 and 2 except that additional wood pulp on a percent solid basis was added.

3 Component % Solids Basis NaCMC 9.19 guar gum 6.13 glycerin 5.05 wood pulp 79.63

[0027] The slurry was cast at a slit width of 26.5 mm and a casting speed of 50 ft / min. The plug wrap material had a yellow color, a smooth texture and good strength. The plug wrap material dispersed in water in about 75 minutes with no stirring and about 8 minutes with slight stirring.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com