Truss and joist brace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

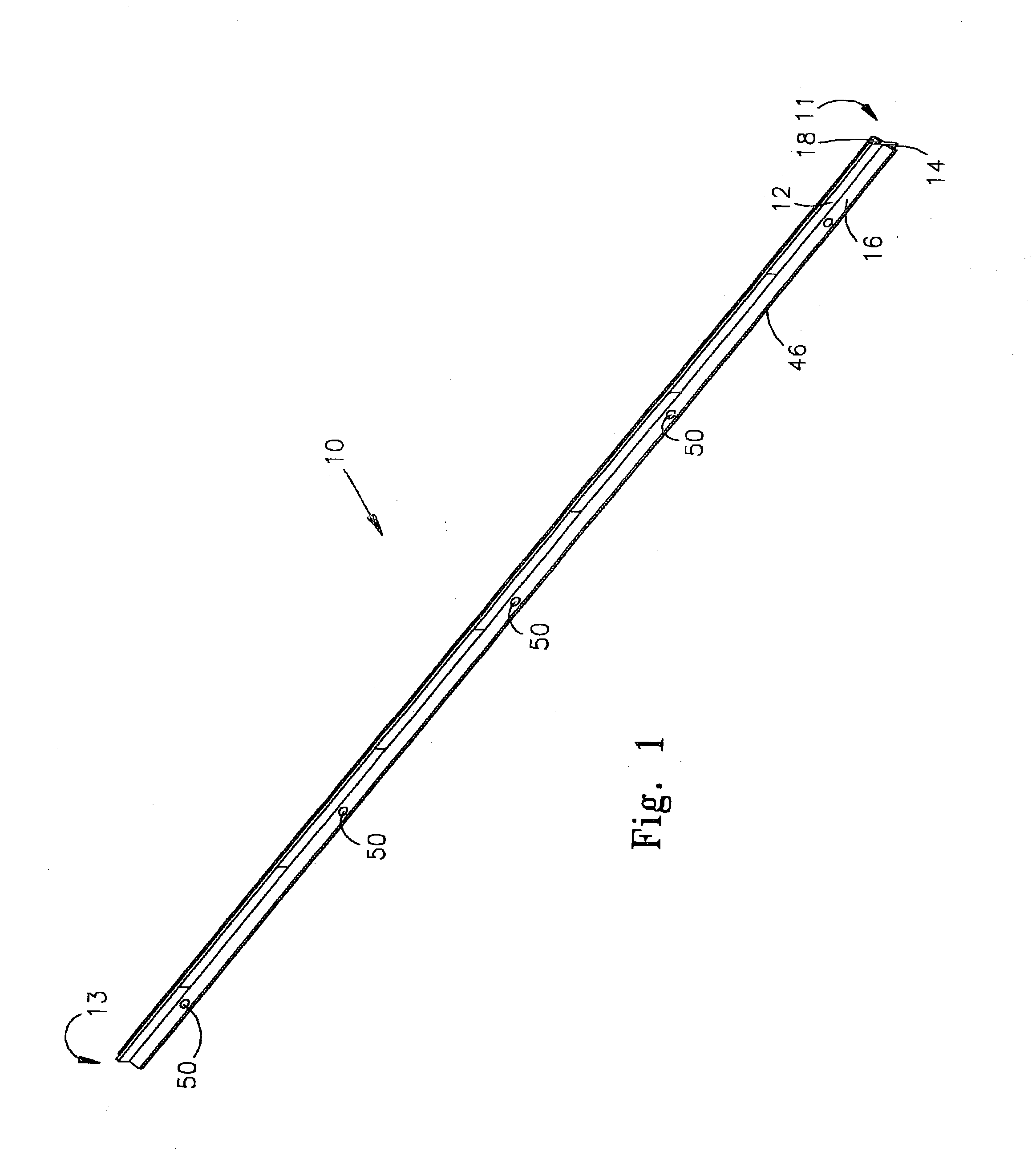

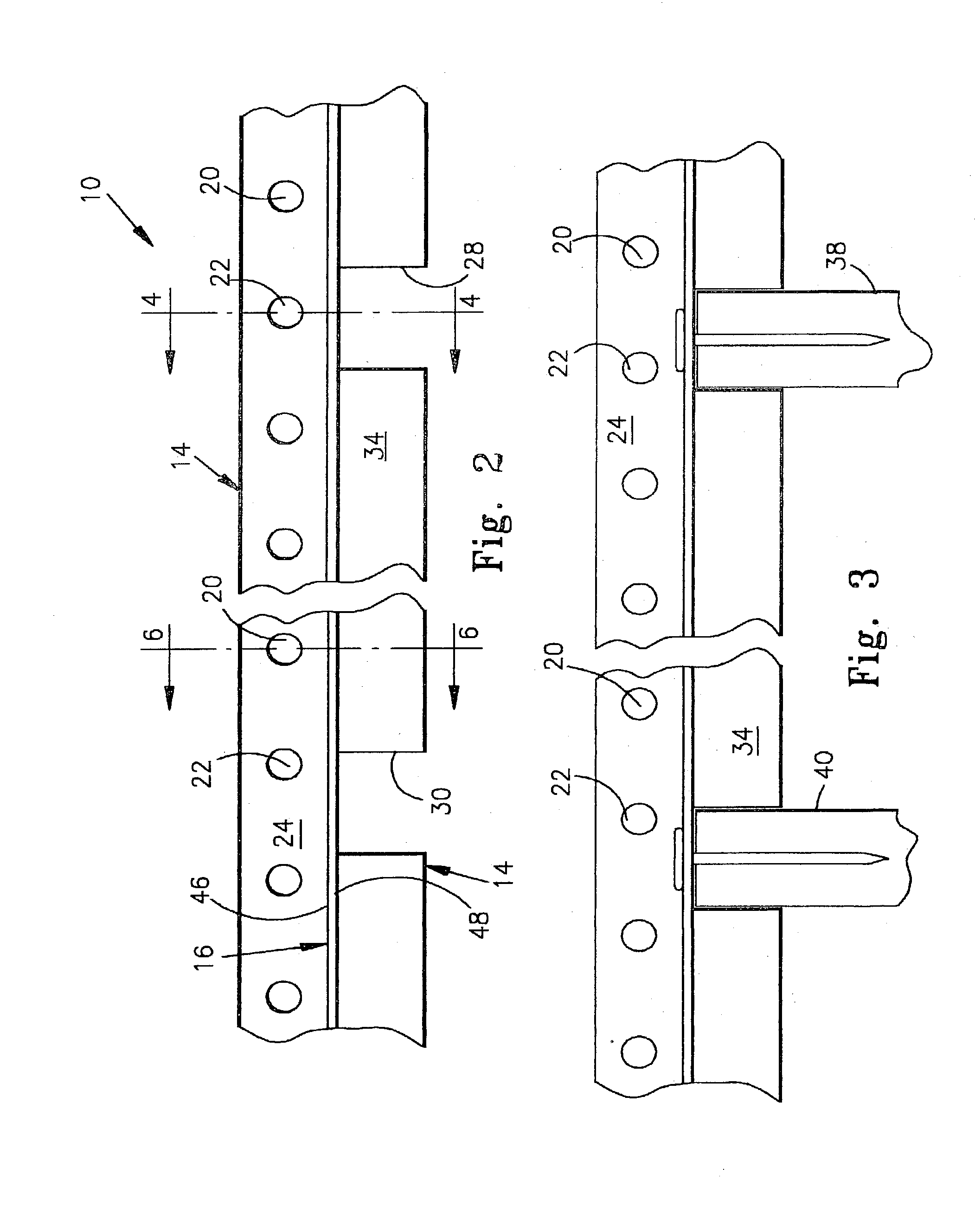

embodiment 100

[0075] T-shaped spacer 100 includes a first end 102 and a second end 104, along with a vertically extending, frame engaging leg 106, and a wing 108 comprised of first 110 and second 112 wing portions. First wing portion 110 is generally similar in its position and lateral extent to the first wing of spacer 10, and also to second wing portion 112. The first and second wing portions 110, 112 are co-planar, and are disposed in a plane generally perpendicular to the plane in which the vertical leg 106 is disposed. As best shown in FIG. 9, the T-Brace embodiment 100, in cross section is formed from a single elongated strip that is rolled and bent to a first laterally extending wing portion 110 that is generally one sheet thick except for the double sheet thickness rolled end flange 111.

[0076] A hemicylindrical stiffening rib 113 is formed to extend the length of the T-Brace 100. Second laterally extending wing portion 112 is generally a similar mirror image of first wing portion 110, and...

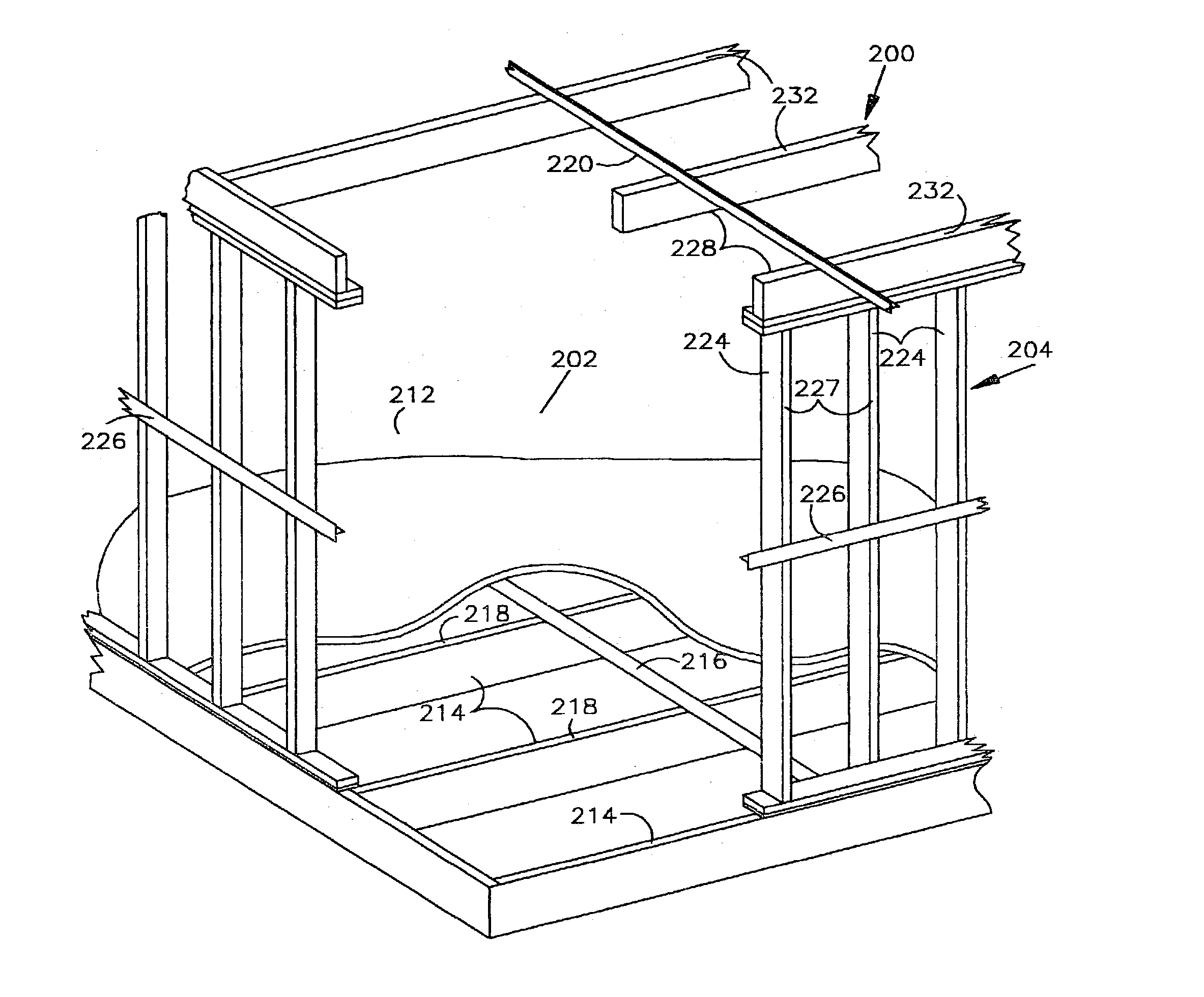

embodiment 400

[0088] Turning now to FIGS. 13 and 14, an alternate embodiment 400 is shown that is particularly well adapted at receiving I-Joist such as are commonly used in floor systems. I-Joist Brace 440 is generally similar in configuration to T-Braces 100 and 300, except that it includes a multi-part break away tab that is designed to accommodate I-Joists 440 having laterally extending legs 446 of varying widths. Similar to the T-Braces discussed above, the break away tabs forming the cut out portions 406 can be arrayed in more than one series to accommodate different spacing regimes. Additionally, the break away tabs can be configured similarly to the break away tab 350 of brace 300, insofar as they can be hingedly coupled to the vertically extending leg 404 of the T-Brace 400, rather than being complete "break away" tabs, as is discussed in connection with the embodiments shown in FIGS. 13 and 14.

[0089] T-Brace 400 includes a laterally extending wing 402 that is generally similar to the T-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com