Adhesive roller

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

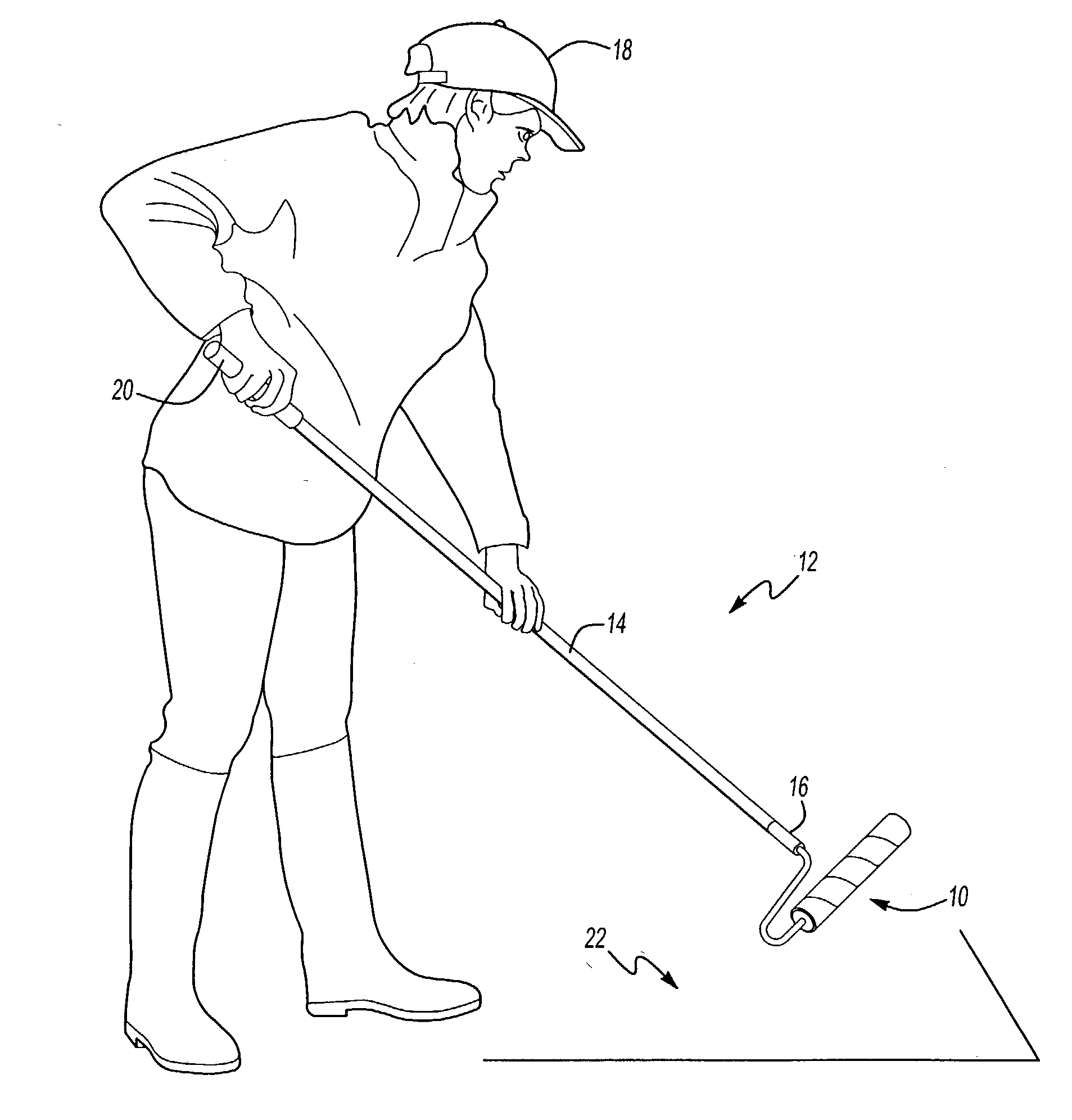

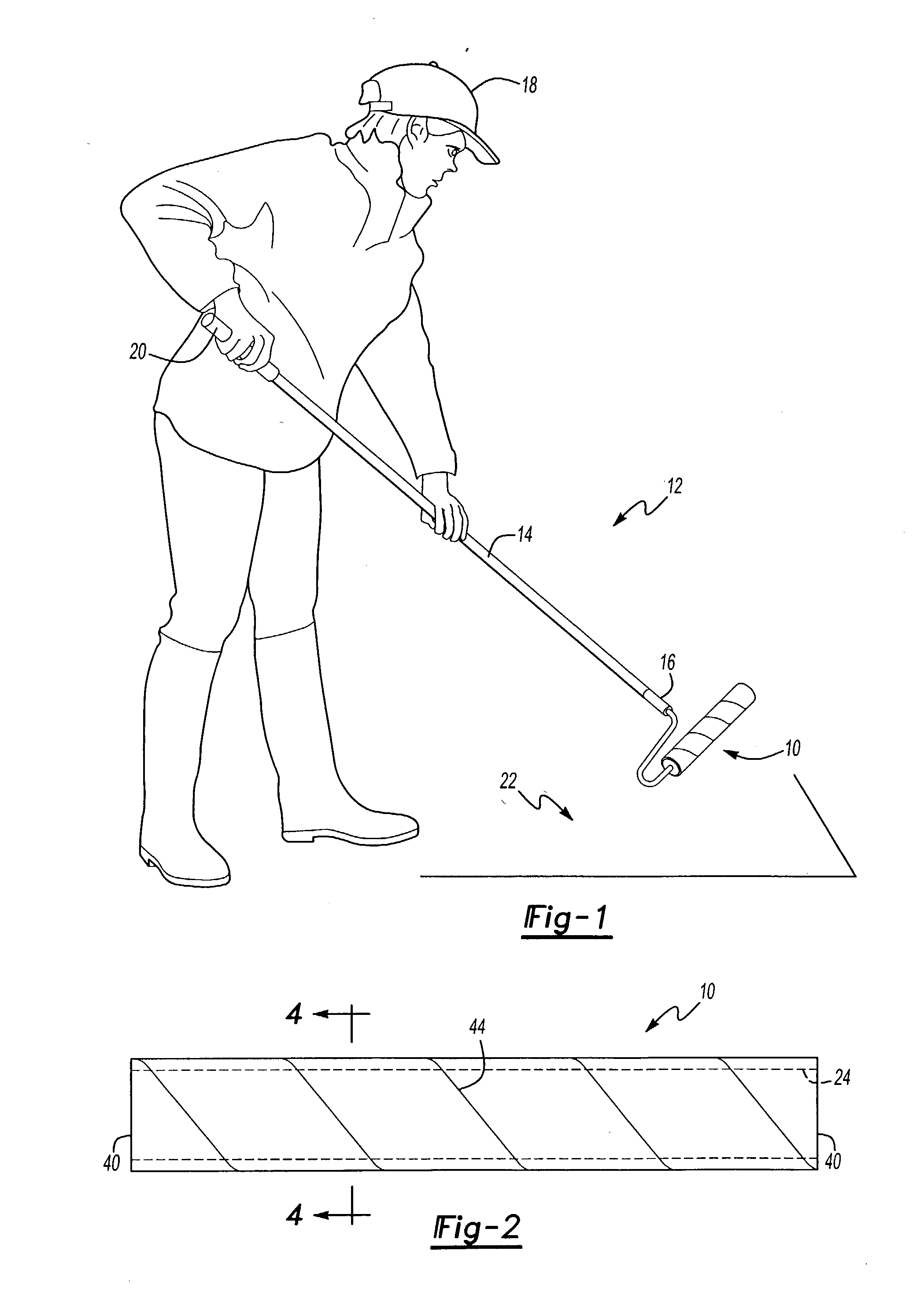

[0021] With reference first to FIG. 1, a preferred embodiment of the adhesive roller 10 of the present invention is shown when used with a cleaner 12. In the conventional fashion, the cleaner 12 includes an elongated handle 14 and in which the adhesive roller 10 is transversely rotatably mounted to one end 16 of the handle 14. In use, a user 18 grasps the opposite end 20 of the handle 14 and rolls the roller 10 along the ground to remove dirt, pet hair, detritus and other debris from the surface 22 to be cleaned.

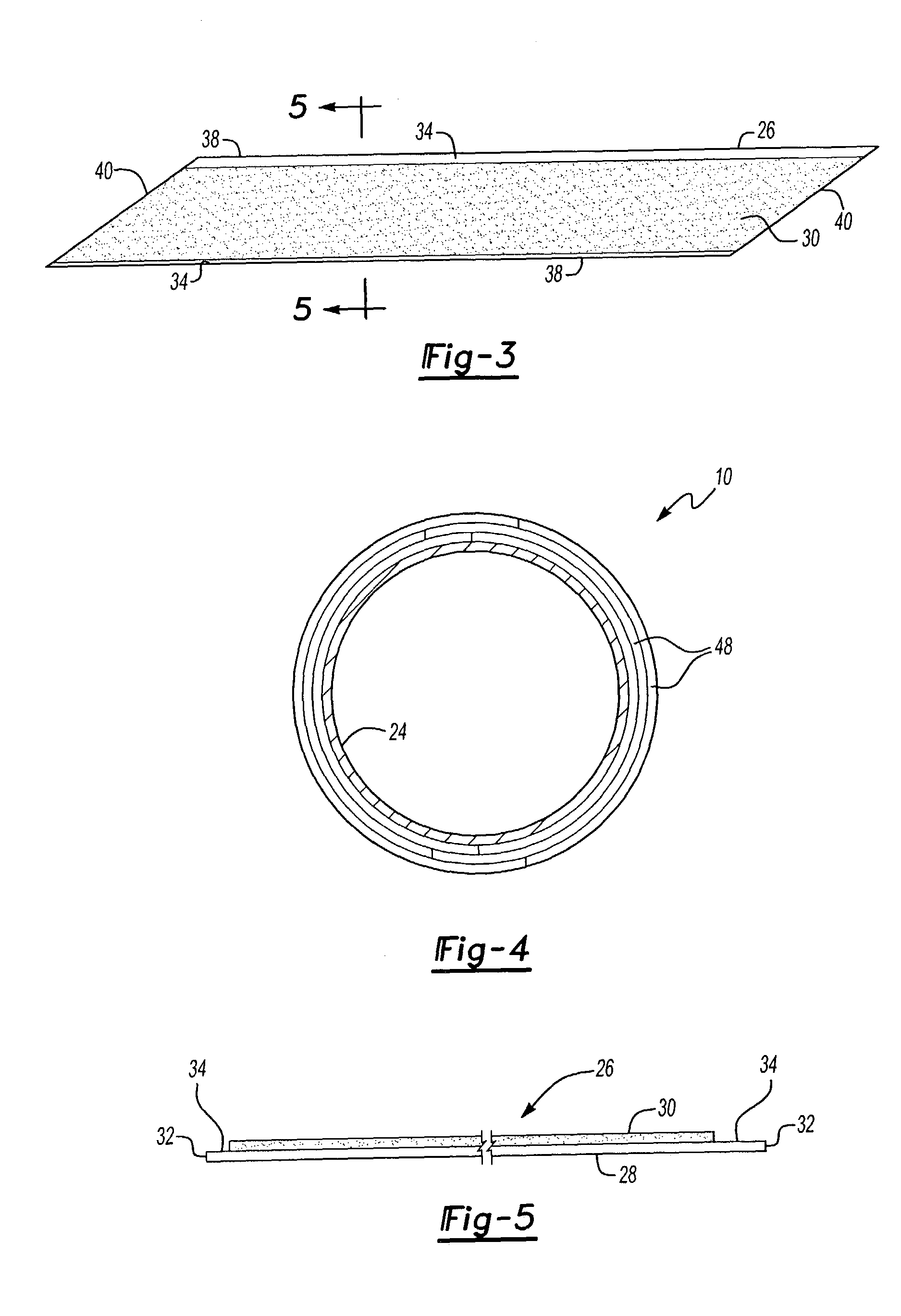

[0022] With reference now to FIGS. 2 and 4, the adhesive roller 10 is there shown in greater detail and comprises a tubular and cylindrical core 24 having a pre-determined outer peripheral surface area. The core 24 is preferably constructed of cardboard although other materials may alternatively be used. Additionally, the roller 10 is at least six inches in axial length, and preferably eight inches or more.

[0023] With reference now to FIGS. 3 and 5, the adhesive roller furth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com