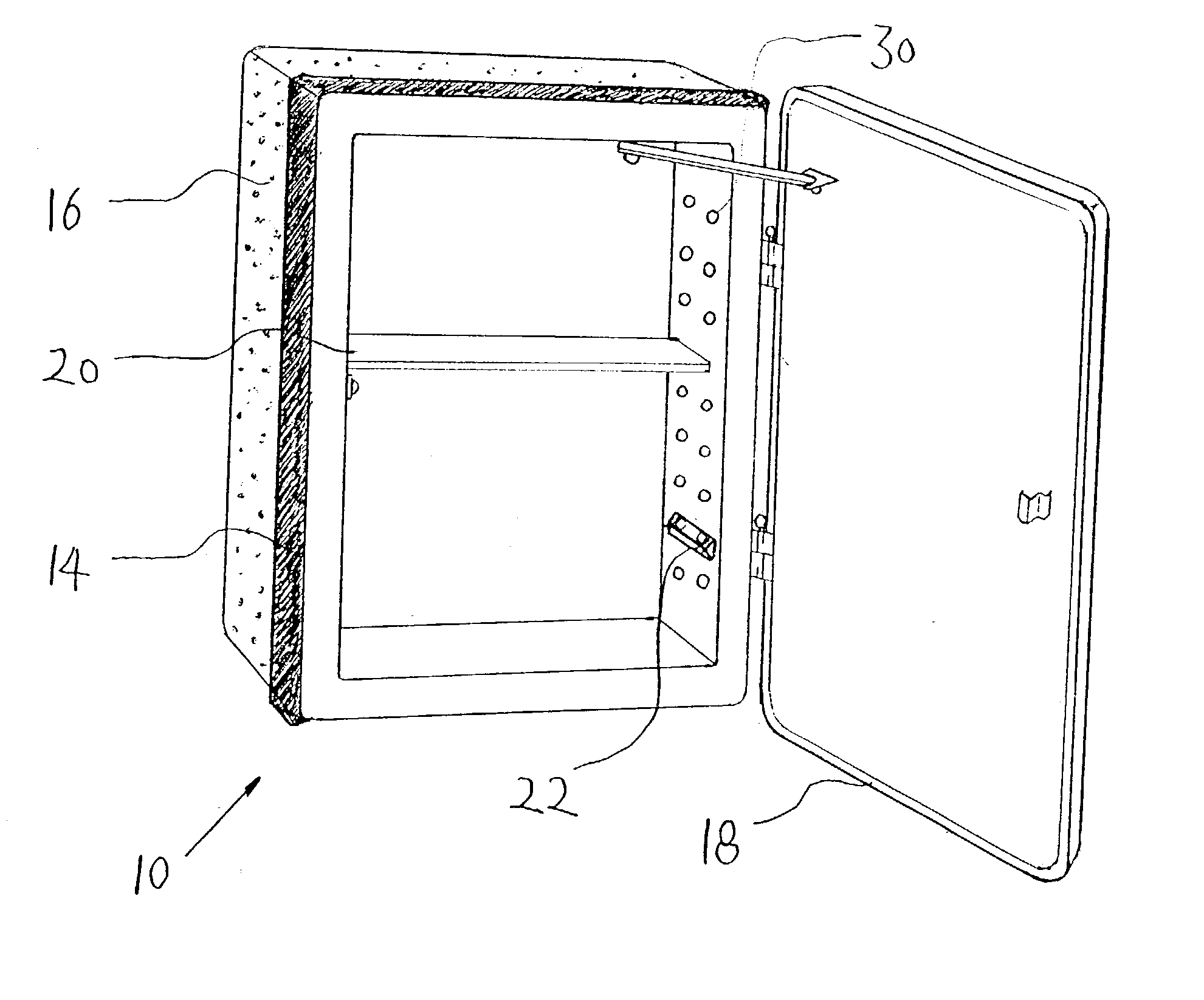

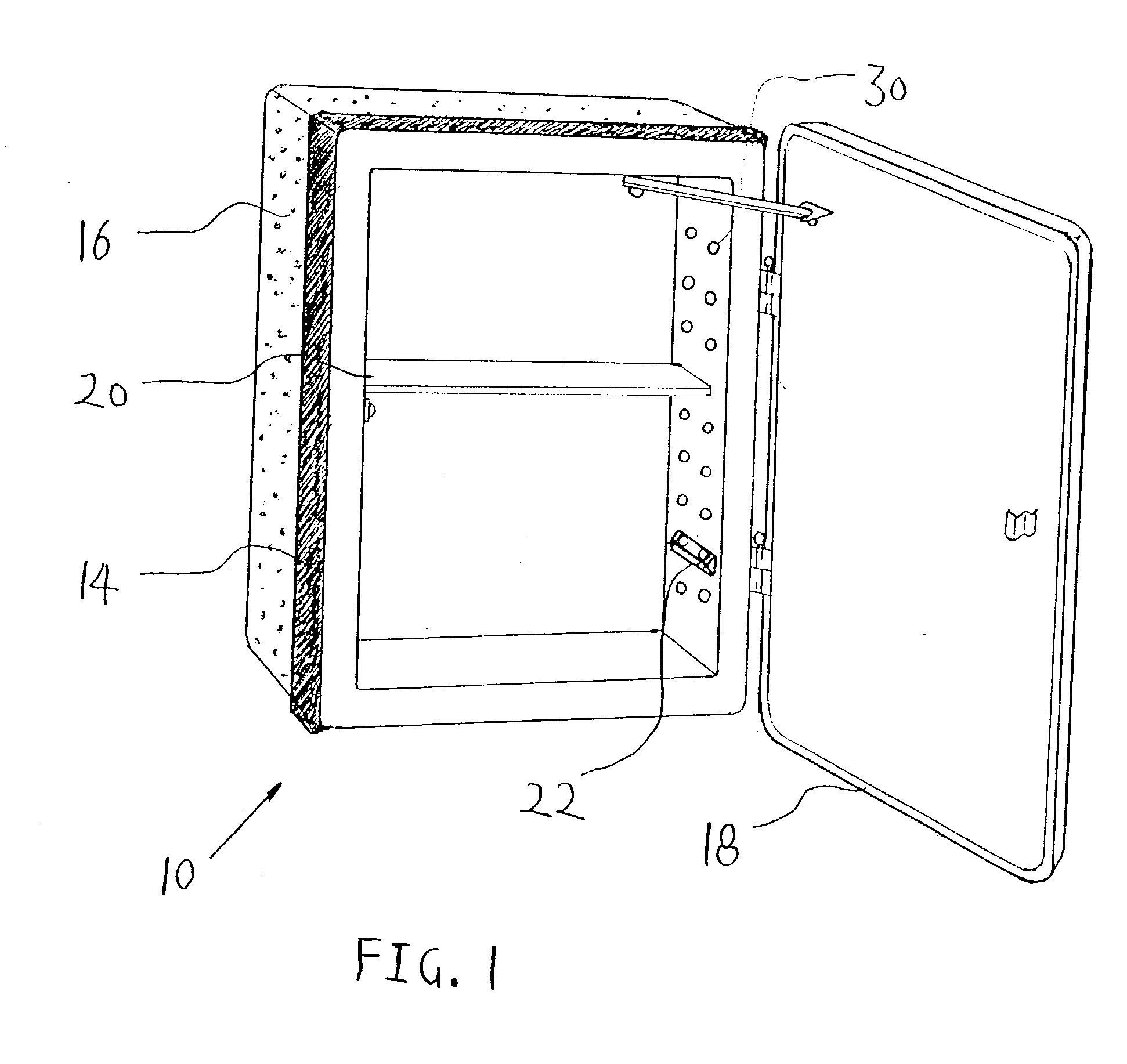

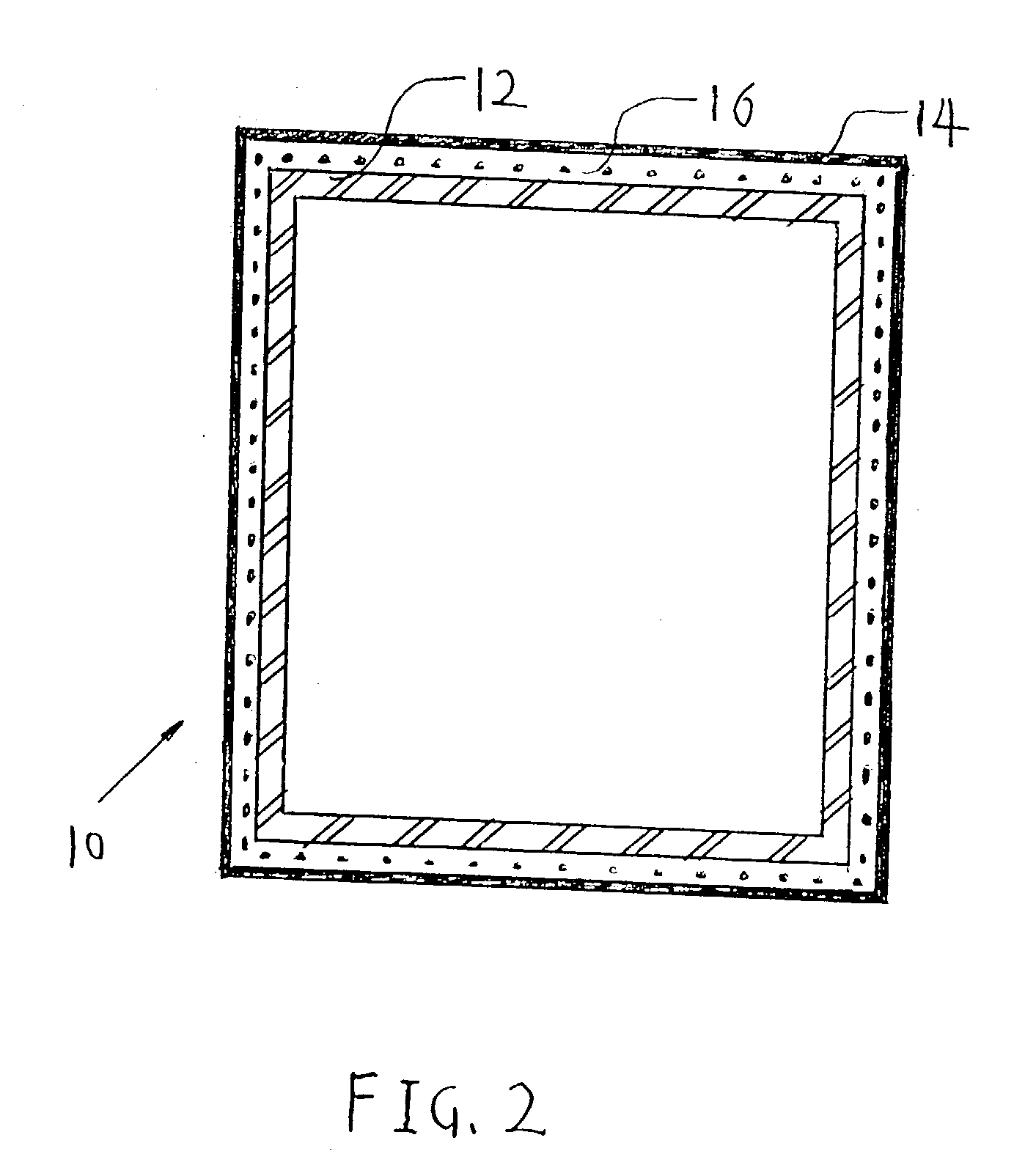

Insulated cabinet and method of installation

a technology for insulating cabinets and recesses, applied in cabinets, dressing tables, furniture parts, etc., can solve the problems of no teaching or suggestion, contractors often omit insulating the recesses as being unduly costly and time-consuming,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] As used herein, the flame retardant backing can be made of any suitable materials with fire retardant qualities. For example, the flame retardant backing may be unitary sheets of a material which is of light weight but good flame retardancy, such as Styrofoam that can be fixed to the outer surface of the cabinet as by adhesions, screws, or other securing elements. The cabinet insulation may be of similar types of materials that may be sprayed on or perhaps extruded into a mold with the rear portion of the cabinet be disposed in the mold cavity. Indeed the flame retardant material can be sheet rock which is cut to a required size in a factory and then fixed to the back wall and the peripheral side wall of the cabinet by adhesives, screws, etc to enable the cabinet maker to sell the insulated cabinet as a unit product which enables the building contractor to avoid time and expense of insulating the cabinet in situ.

[0029] As used herein, the fireproof seal can be any suitable co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com