System and process for treating waste gas employing bio-treatment technology

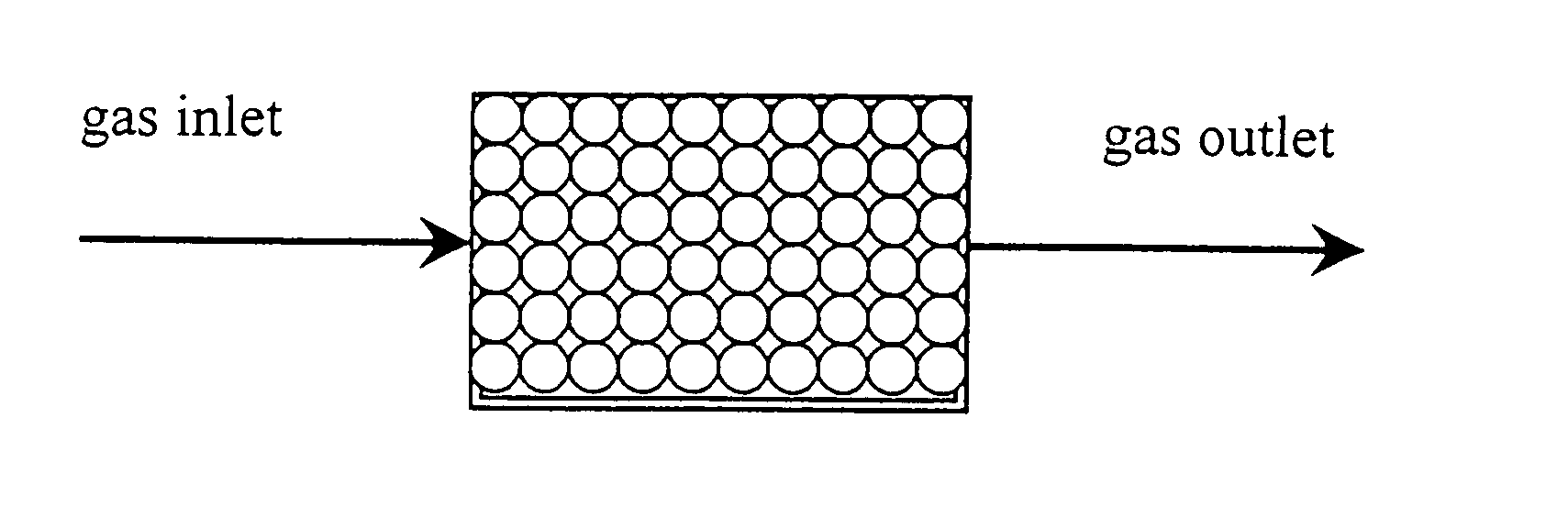

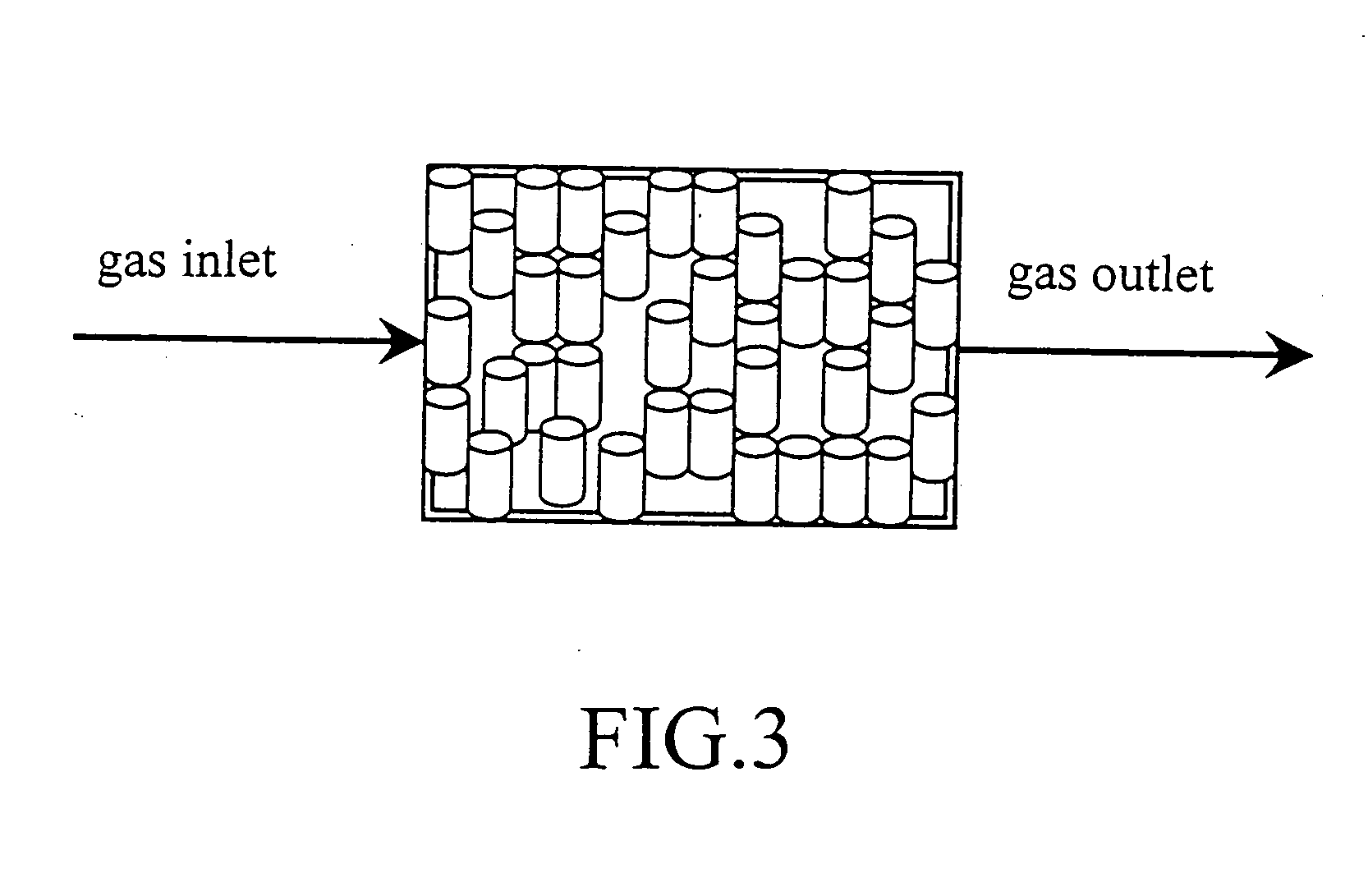

a bio-treatment technology and waste gas technology, applied in the direction of moving filter element filters, separation processes, filtration separation, etc., can solve the problems of increasing the pressure loss, affecting the flow of the reactor, and limiting the use of bio-treatment technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

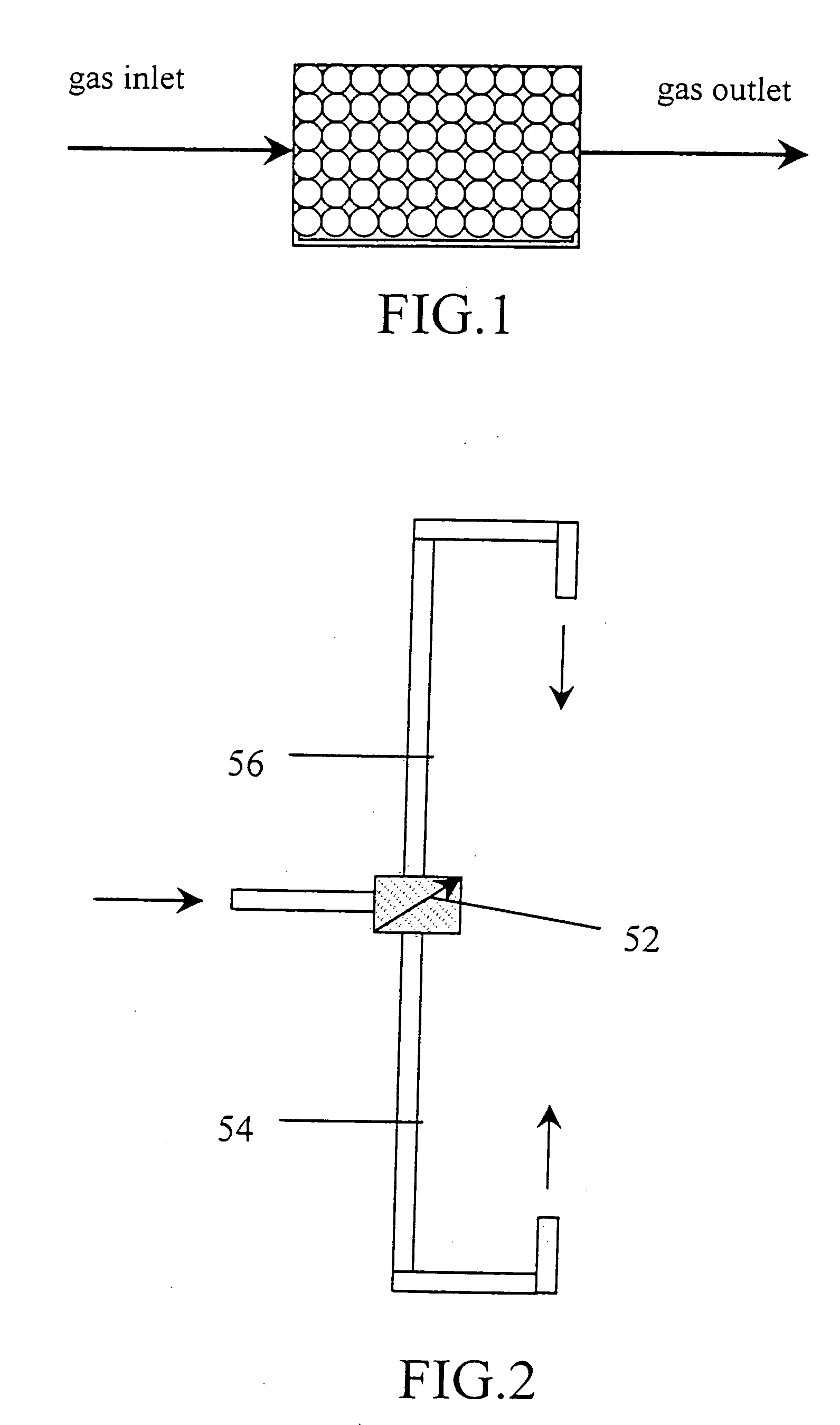

[0012] The preferred embodiment of the claimed invention is illustrated in FIG. 4, and comprises a conventional biotrickling filter system, in association with a dust / grease filtering device 1, a two-way directionally gas inlet system 5, a bioaerosol removal device 9 and a cell immobilization unit 11.

[0013] The conventional biotrickling filter system primarily includes a liquid spraying reservoir 12, a plurality biological reactors 13, a nutritional salt preserving reservoir 14 for furnishing nutrition that is required at the growth of microorganism. The periphery of the system includes a ventilating far 2, a flow meter 3, pressure drop meters 6, a liquid filtering device 7, a liquid circulating flow water pump 8, sampling holes 10.

[0014] According to the preferred embodiment, the waste gas to be treated enters the dust / grease filtering device 1. By means of conveyance due to the ventilating fan 2, the waste gas is conveyed from the flow meter 3 and the two-way directional gas inlet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh size | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com