Lubricating oil composition for internal combustion engine

Inactive Publication Date: 2004-12-02

NIPPON OIL CORP

View PDF13 Cites 56 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

0036] Component (B) of the lubricating oil composition of the present invention is a succinimide and/or derivative thereof.

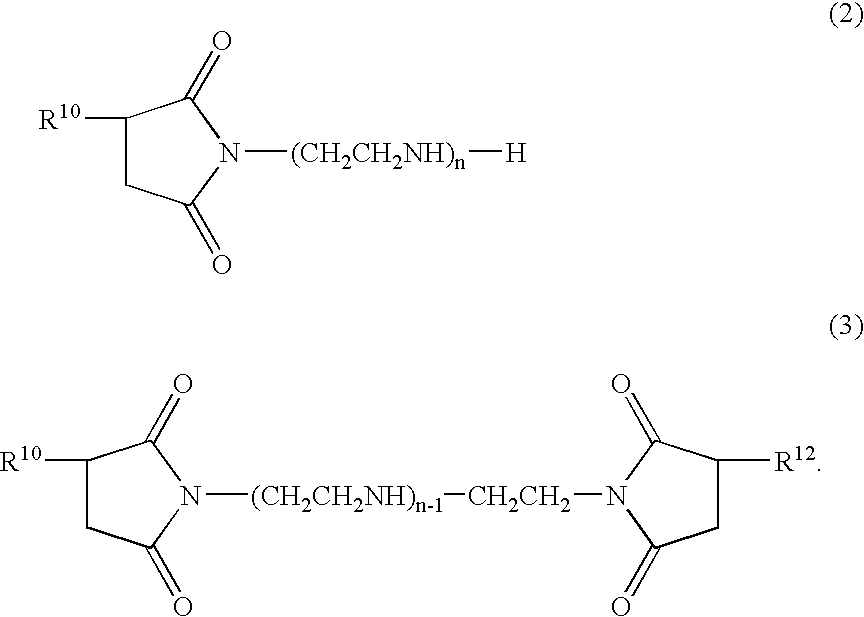

0037] Examples of succinimide are monosuccinimides represented by formula (2) below and bissuccinimides represented by formula (3) below: 1

0038] In formulas (2) and (3), R.sup.10, R.sup.11, and R.sup.12 are each independently a polybutenyl group and n is an integer of from 2 to 7. In the present invention, preferred are bis-type succinimides represented by formula (3) because they can further enhance the advantageous effects achieved by the present invention.

0039] The polybutenyl group of R.sup.10, R.sup.11, and R.sup.12 has a number-average molecular weight of preferably 700 or greater, more preferably 900 or greater and preferably 3,500 or less, more preferably 2,500 or less, and particularly preferably 1,500 or less. A polybutenyl group having a number-average molecular weight of 700 or greater makes it possible to produce a lubricating oil composition with excellent detergent and dispersion properties. Whereas, a polybutenyl group having a number-average molecular weight of 3,500 or less makes it possible to produce a lubricating oil composition with more excellent low-temperature flowability. With the objective of excellent advantageous effects of suppressing sludge formation, the lower limit of n is 2 and preferably 3, while the upper limit of n is 7 and preferably 6. The polybutenyl group can be obtained from polybutene (polyisobutene) produced by polymerizing a mixture of 1-buten and isobutene or a highly purified isobutene using a catalyst such as aluminum chloride or boron fluoride. The polybutene mixt

Problems solved by technology

Such lubricating oils are poor in oxidation stability and tend to be acceleratingly decreased in base number.

After an extensive research and study, focusing on the ability to retain the base number of lubricating oils for internal combustion engine containing a large amount of sulfur, it was found that a compound containing sulfur such as ZDTP itself generates sulfuric acid in the lubricating oil when oxidized or thermally decomposed, and thus the lubricating oil containing such a compound is exhausted in base number, leading to a shortened working life, significantly deteriorated in detergency particularly at high temperature, and poor in low friction characteristics.

It was also fou

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

A lubricating oil composition for internal combustion engine, comprising a lubricating base oil; (A) a triphosphate represented by formula (1) below in an amount of 0.01 to 0.2 percent by mass in terms of phosphorus; (B) succinimide and/or derivative thereof in an amount of 0.01 to 0.3 percent by mass in terms of nitrogen; (C) an alkali metal or alkaline earth metal detergent in an amount of 0.05 to 1 percent by mass in terms of metal; and (D) a phenol-based and/or amine-based anti-oxidants in an amount of 0.01 to 3 percent by mass: O=P(OR<1>)3 (1) wherein the groups of R<1 >are each independently a hydrocarbon group having 1 to 30 carbon atoms and are the same or different from each other. The lubricating oil composition is excellent in anti-wear properties, base number retaining properties, high temperature detergency, and low friction characteristics.

Description

[0001] The present invention relates to lubricating oil compositions for internal combustion engines and particularly to those having excellent anti-wear properties, base number retaining properties, high-temperature detergency, and low friction characteristics.[0002] Zinc dialkyldithiophosphates (ZDTP) have excellent anti-wear properties and anti-oxidation properties as a peroxide decomposer and thus have been used as an essential additive in lubricating oils for internal combustion engines or in every sort of lubricating oils.[0003] On the other hand, lubricating oil compositions blended with zinc dialkyldithiocarbamates and sulfur-based additives so as to retain the anti-wear properties are known as ZDTP-free lubricating oils as disclosed in Japanese Patent Laid-Open Publication Nos. 52-704, 62-253691, 63-304095, and 6-41568 and Published Japanese Translation Nos. 62-501572, 62-501917, and 1-500912. The lubricating oils disclosed in these publications contain a large quantity of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10M163/00

CPCC10M163/00C10M2207/023C10M2207/026C10M2207/262C10M2207/289C10M2215/06C10M2215/064C10M2215/086C10M2215/28C10M2219/00C10M2219/044C10M2219/046C10M2223/04C10M2223/041C10M2223/045C10M2227/09C10N2210/01C10N2210/02C10N2230/04C10N2230/06C10N2230/08C10N2230/10C10N2230/43C10N2230/52C10N2240/10C10N2240/12C10N2010/02C10N2010/04C10N2030/04C10N2030/08C10N2030/06C10N2030/10C10N2030/43C10N2030/52C10N2040/25C10N2040/12

Inventor YAGISHITA, KAZUHIROIGARASHI, JINICHIKOIZUMI, TAKEO

Owner NIPPON OIL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com