Sheet feeding apparatus and image forming apparatus

a technology of feeding apparatus and image forming apparatus, which is applied in the direction of thin material processing, instruments, and article separation, etc., can solve the problems of generating noise, deteriorating the noise level of the printer, and the technique does not address the problem of trailing edge jumping, etc., and achieves the effect of reducing noise and silent operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0036] First Embodiment

[0037] A first embodiment of a sheet feeding apparatus of the present invention will be explained below with a laser beam printer, which is an image forming apparatus adopting an electrophotographic system, as an example.

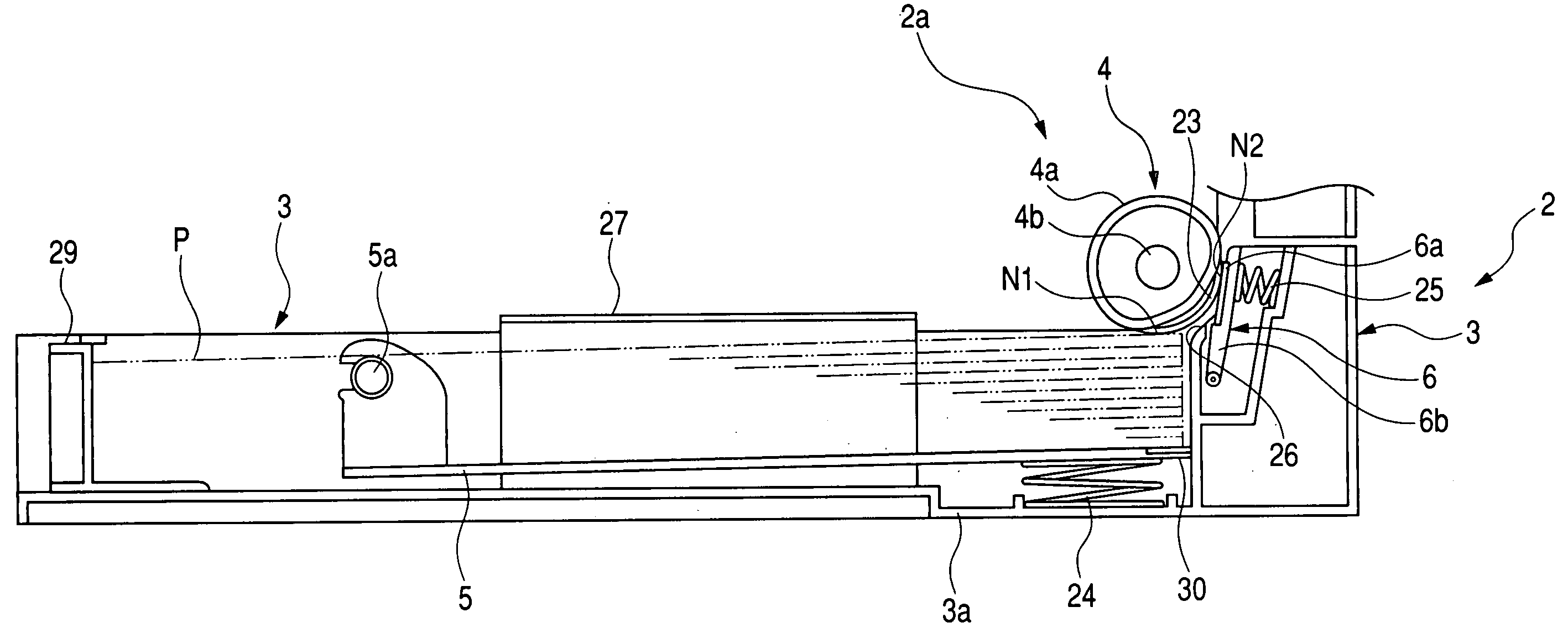

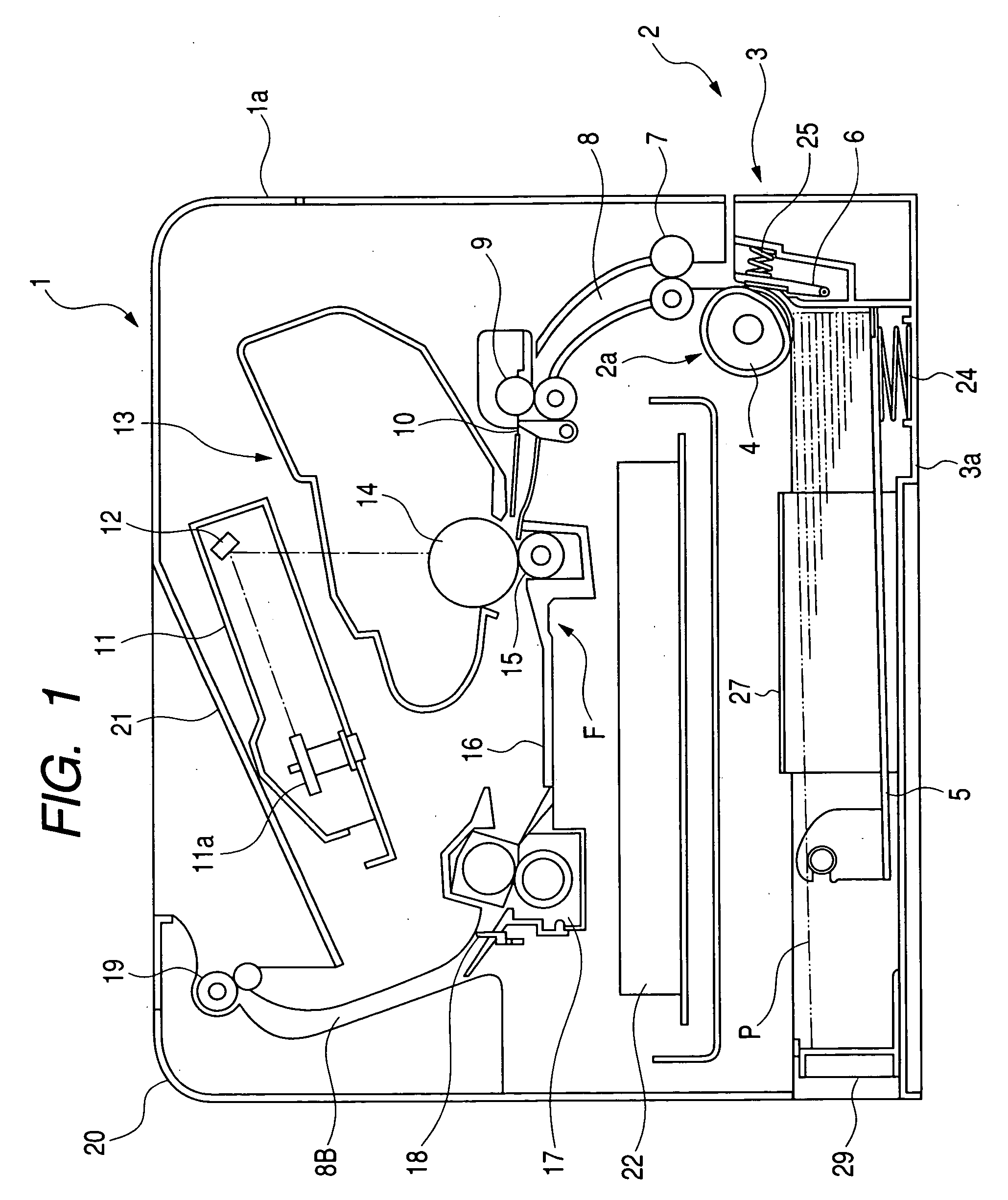

[0038]FIG. 1 is a sectional view of a laser beam printer (hereinafter referred to as printer) 1. FIG. 2 is a sectional view of a sheet feeding apparatus mounted on this printer 1. FIG. 3 is a perspective view of a sheet feeding cassette that is mounted on the sheet feeding apparatus shown in FIG. 1. A structure of the printer 1 will be explained with reference to these figures.

[0039] (Image Forming Portion)

[0040] In FIG. 1, an image forming portion F includes: a process cartridge 13 that is constituted by a photosensitive member 14, and a developing device, a cleaner, a charging roller, and the like, which are not shown in the figure; a transferring roller 15 that transfers a visualized image on the photosensitive member 14 onto a sheet P; ...

second embodiment

[0071] Second Embodiment

[0072] Next, a second embodiment of the sheet feeding apparatus in accordance with the present invention will be explained with reference to FIGS. 8 and 9. Note that only structures and operations different from those in the first embodiment will be explained. The other structures and operations are the same as those in the first embodiment.

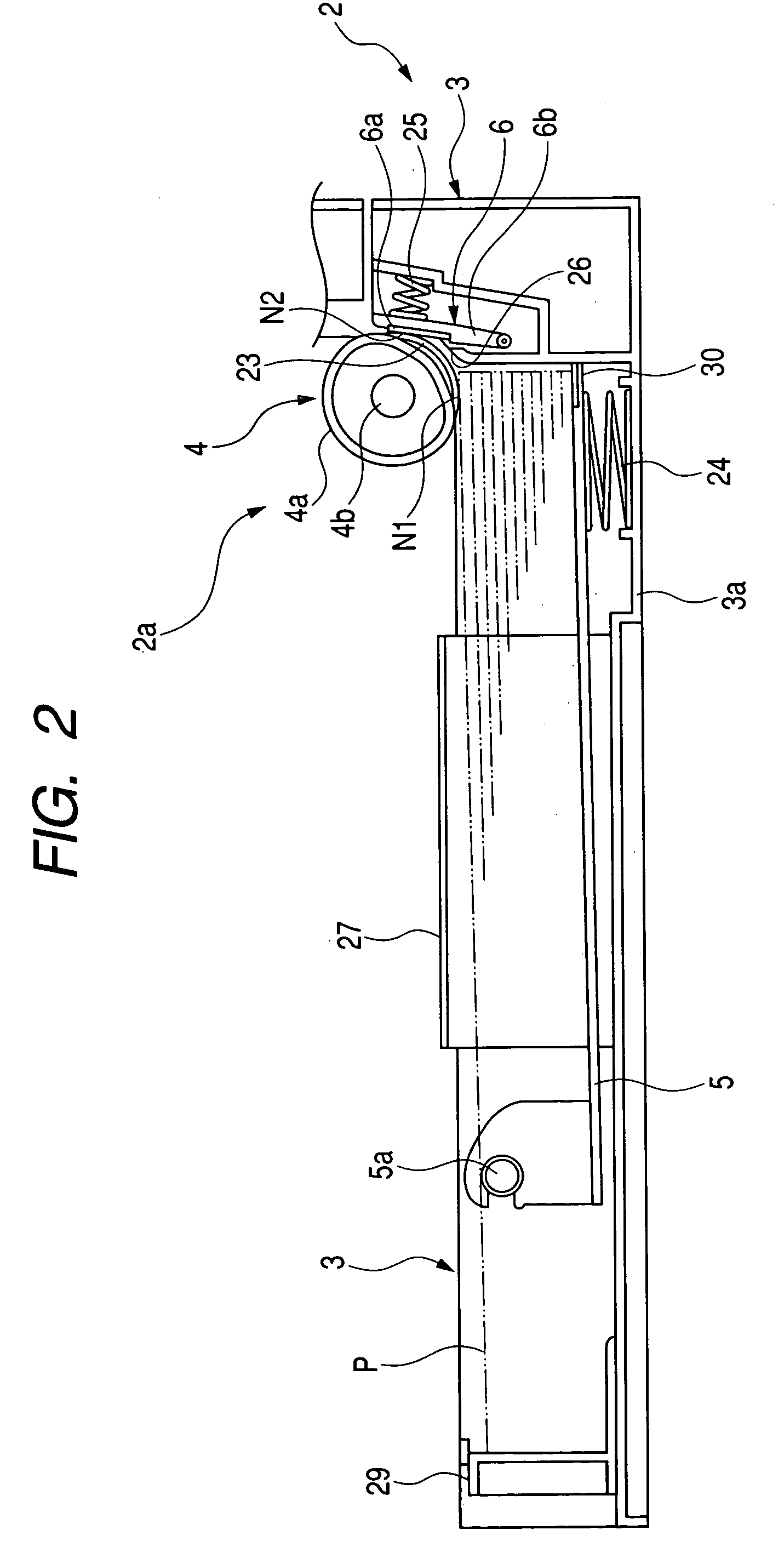

[0073]FIG. 8 is a sectional view of a sheet feeding apparatus 2 in accordance with the second embodiment. FIG. 9 is a perspective view of a sheet feeding cassette 3 that is mounted on this sheet feeding apparatus.

[0074] In the sheet feeding apparatus 2, the inclined guide surface 26, which is provided between the pushing portion N1 where the sheets P are pushed against the sheet feeding roller 4 by the pressure plate 5 and the abutting portion N2 where the sheet feeding roller 4 and the separation pad 6 come into abutment against each other, and which guides the sheets P delivered by the sheet feeding roller 4 toward the...

third embodiment

[0077] Third Embodiment

[0078] Next, a third embodiment of the sheet feeding apparatus in accordance with the present invention will be explained. FIG. 10 is a main part sectional view of the sheet feeding apparatus in accordance with the third embodiment. Only structures and operations different from those of the first and the second embodiments will be described. The other structures and operations are the same as those in the first and the second embodiments.

[0079] In the sheet feeding apparatus 2, the sheet guide surface 26 is formed in an arc shape with an inner diameter surface thereof serving as a sheet guide. The sheet guide surface 26 is provided between the pushing portion N1, where the sheets P are pushed against the sheet feeding roller 4 by the pressure plate 5, and the abutting portion N2, where the sheet feeding roller 4 and the separation pad 6 come into abutment against each other, and guides the sheets P delivered by the sheet feeding roller 4 toward the abutting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com