Composite building block having moisture barrier and insulation element

a technology of moisture barrier and insulation element, which is applied in the direction of structural elements, building components, construction materials, etc., to achieve the effect of preventing unwanted movemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

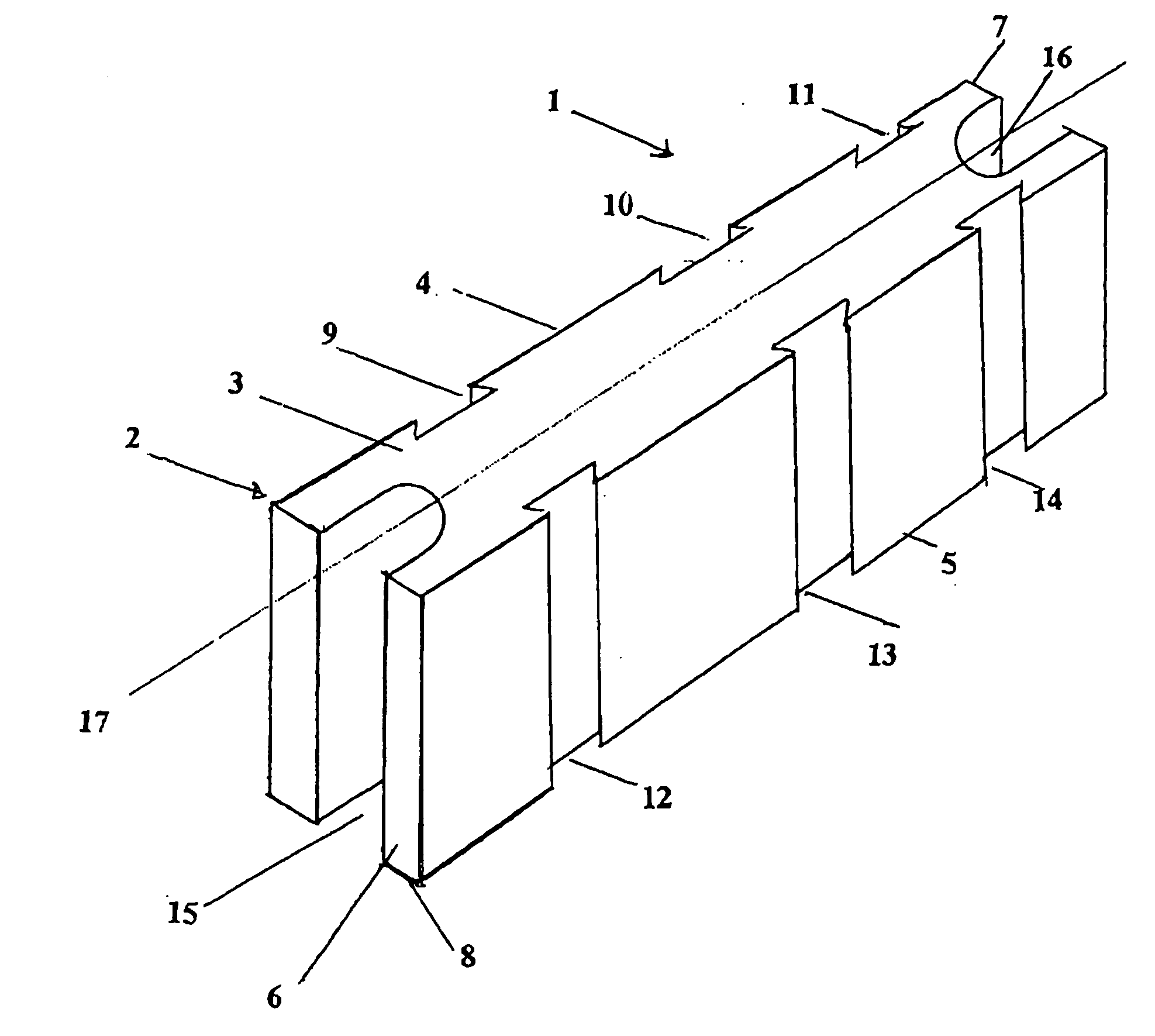

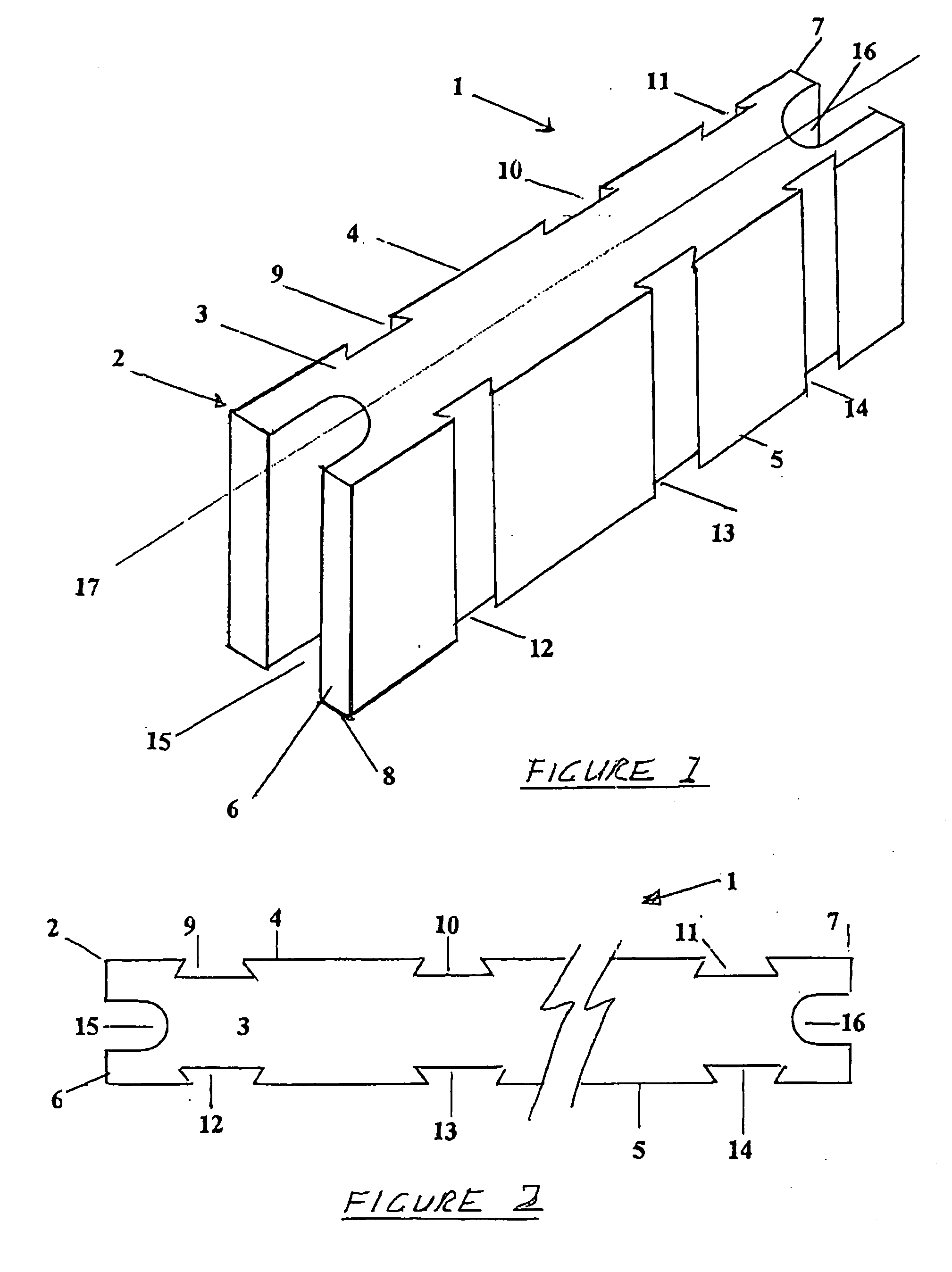

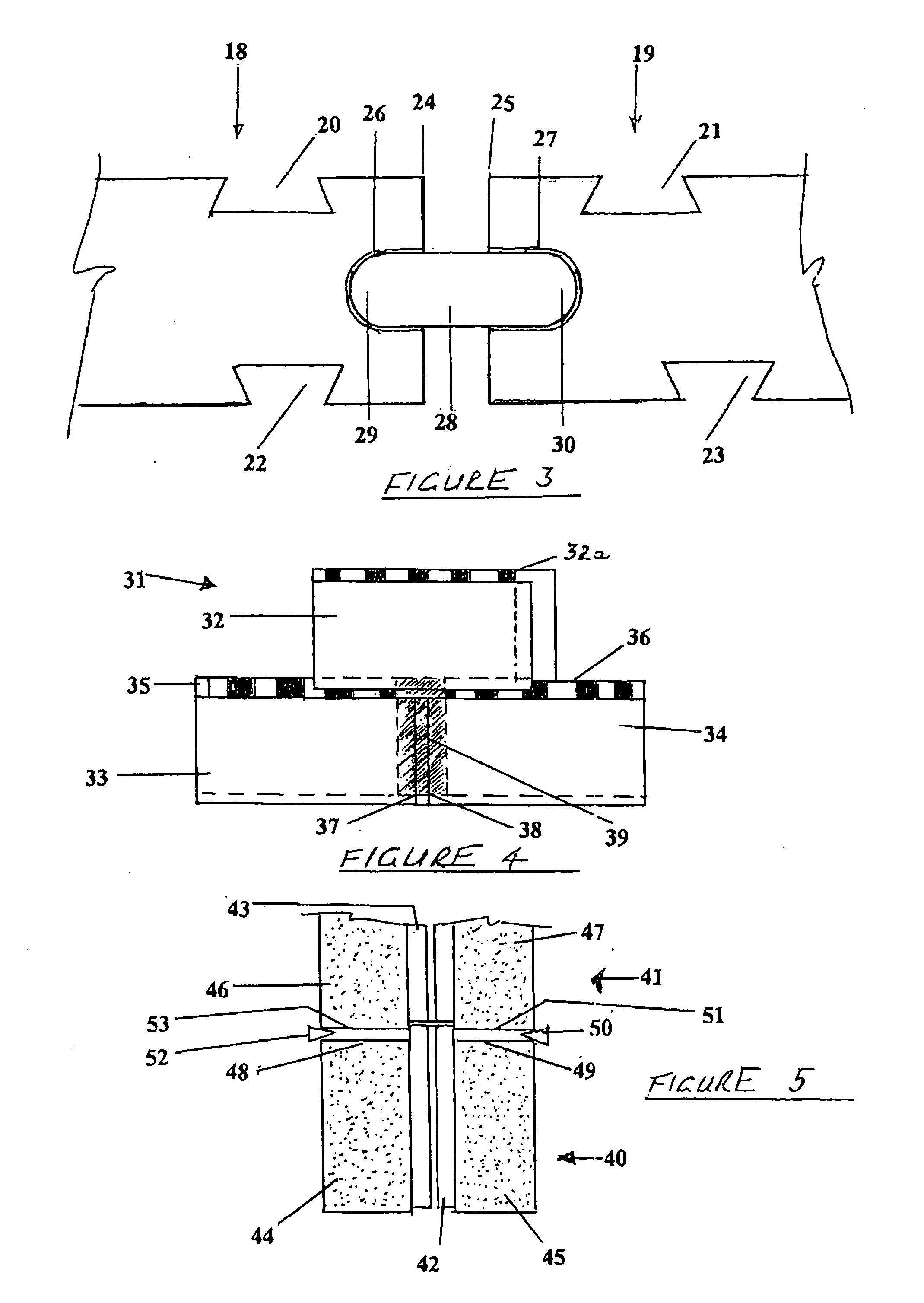

[0072]FIG. 1 shows a perspective view of a polystyrene insulating element profile 1 according to one embodiment. Element 1 is adapted for use in building blocks used in the construction of structures and preferably elemental structures such as but not limited to walls both structural and internal non load bearing. Element 1 is integrally fitted to a construction block during manufacture of the block such that an integral composite is formed it may be fitted after construction of the block and during construction of a structure inwhcih the blocks are to be used.

[0073] Preferably, element 1 comprises a prismic body made from a material having high insulating properties and is insertable adjacent or in at least one said building blocks to thereby provide a thermal and water barrier to at least one face of each said building blocks. In a preferred embodiment, Element 1 is a generally elongate and approximates the length of a brick which with it will be used. For the purpose of integral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com