Presulfiding OCR catalyst replacement batches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

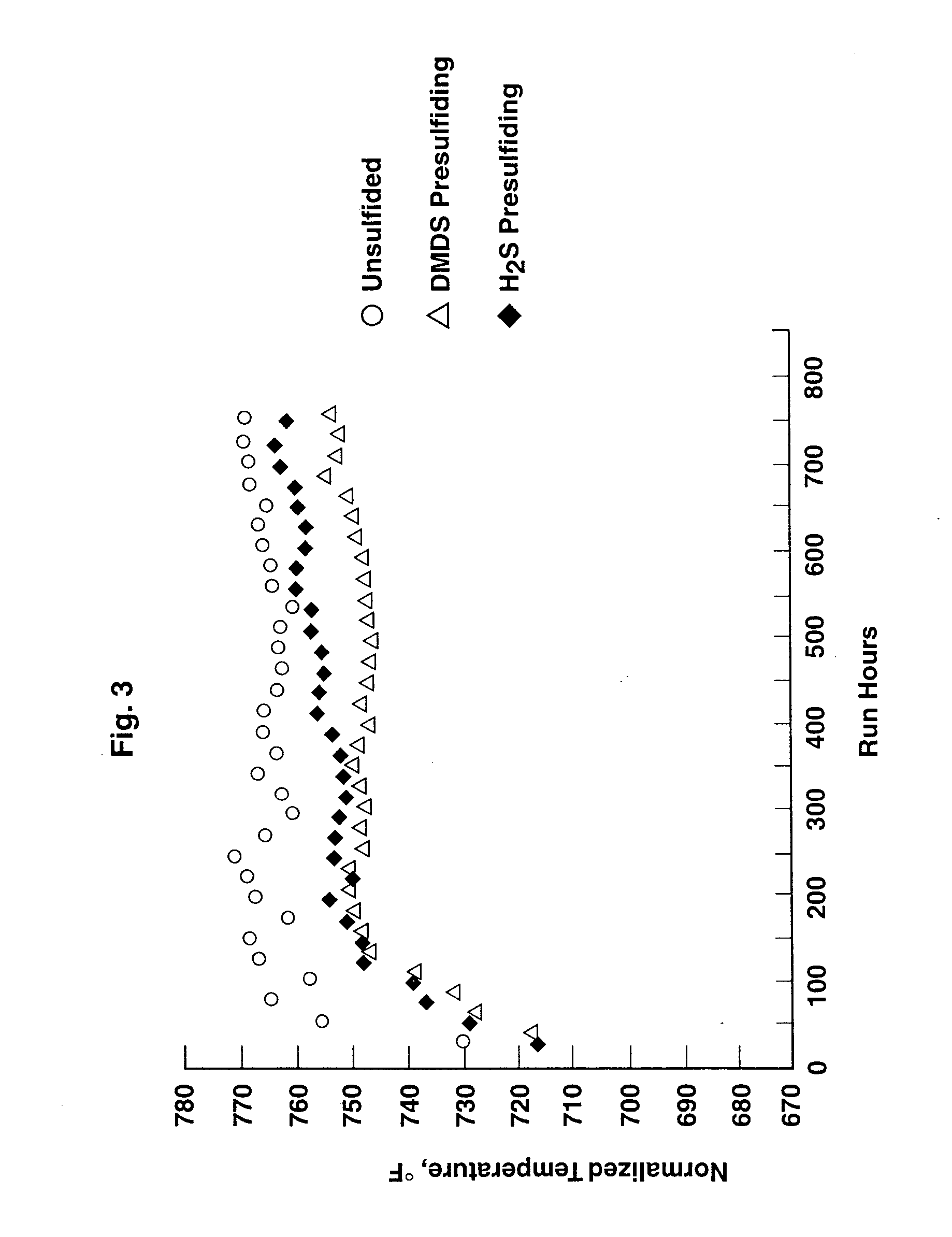

The catalytic particulates comprised an alumina porous carrier material or alumina inorganic support. Deposited on and / or in the alumina porous carrier material was an oxidic hydrotreating catalyst component consisting of NiO and / or MoO3. The Mo was present on and / or in the alumina porous carrier material in an amount of about 3% by wt., based on the combined weight of the alumina porous carrier material and the oxidic hydrotreating catalyst component(s). The Ni was present on and / or in the alumina porous carrier material in an amount of about 1% by wt., based on the combined weight of the alumina porous carrier material and the oxidic hydrotreating catalyst component(s). The surface area of the catalytic particulates was about 120 sq. meters per gram.

The plurality of catalytic particulates were generally spherical with a mean diameter having a value ranging from about 6 Tyler mesh to about 8 Tyler mesh and an aspect ratio of about 1. The mean crush strength of the catalytic part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com