Golf club head and method of fabricating the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

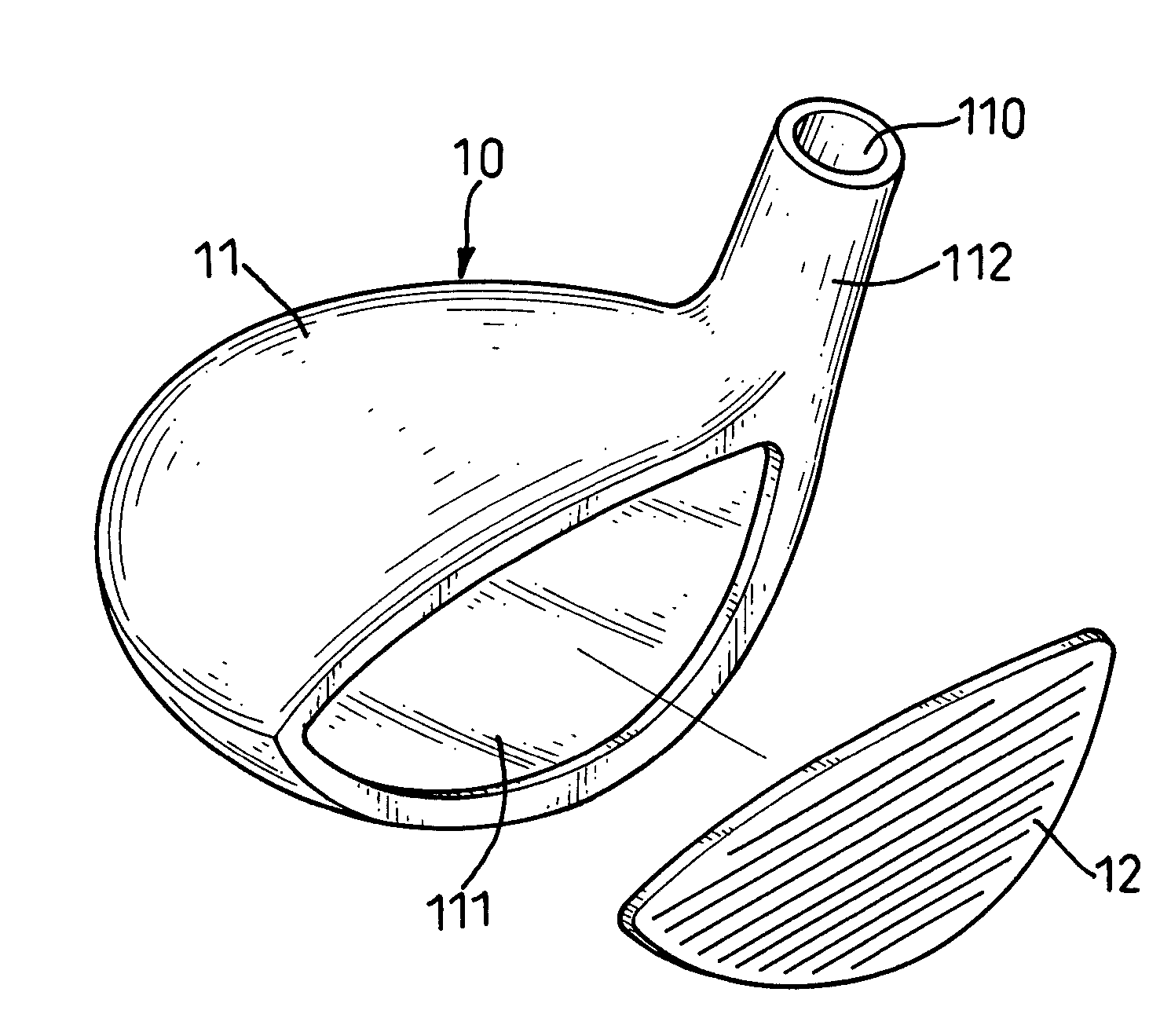

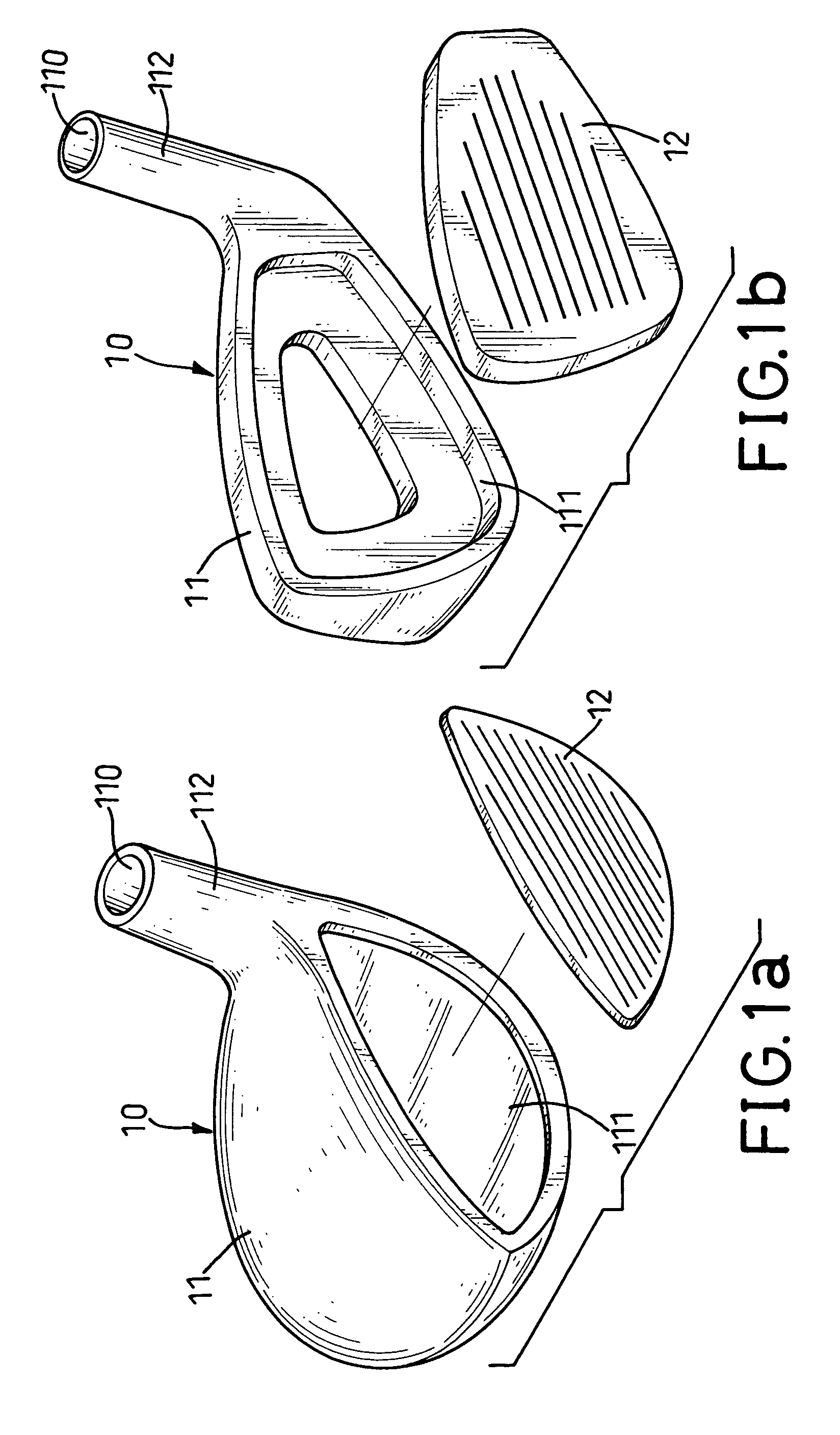

[0033] With reference to FIGS. 1a, 1b and 3, a golf club head (10) for an iron or a wood in accordance with the present invention includes a body (11) and a faceplate (12). The body (11) has a hosel (110), a face (111) and a shank (112). The hosel (110) is defined at the shank (112) and is adapted to connect to a shaft (not shown) of the golf club. The face (111) is formed on the body (11) and is adapted to hit a golf ball (not shown). The face (111) may be a recess in which the faceplate (12) is mounted.

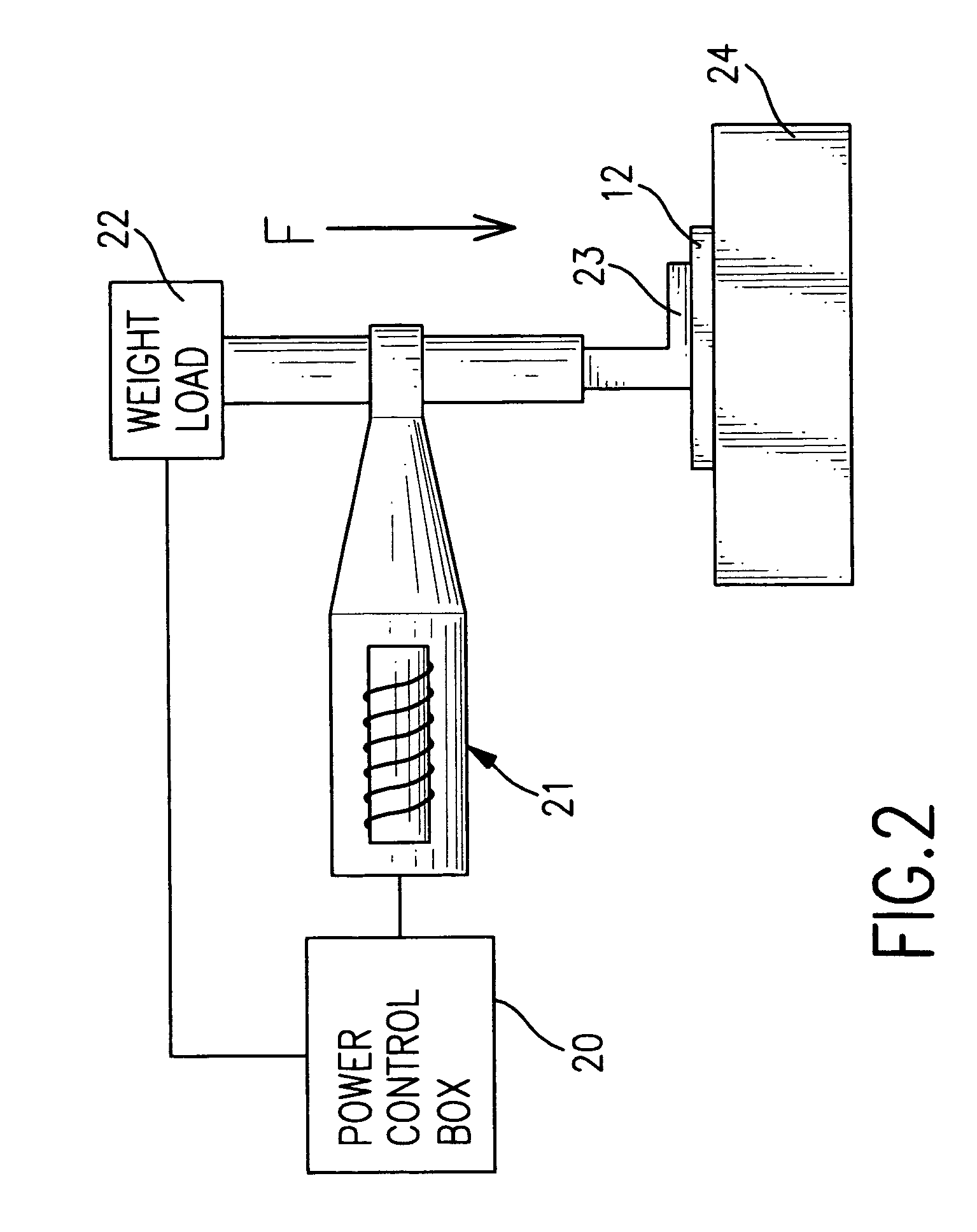

[0034] The faceplate (12) is attached firmly to or formed integrally on the face (111) of the body (11) by welding, forging or other means and has a center of percussion, called a “sweet spot,” and a softened region (121). The sweet spot represents the spot of desired contact with the ball, and the softened region (121) is formed around the sweet spot by a heat treatment technique. The faceplate (12) is made out of high strength precipitation hardening stainless steel (typical of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com