Machine and method for processing textile fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

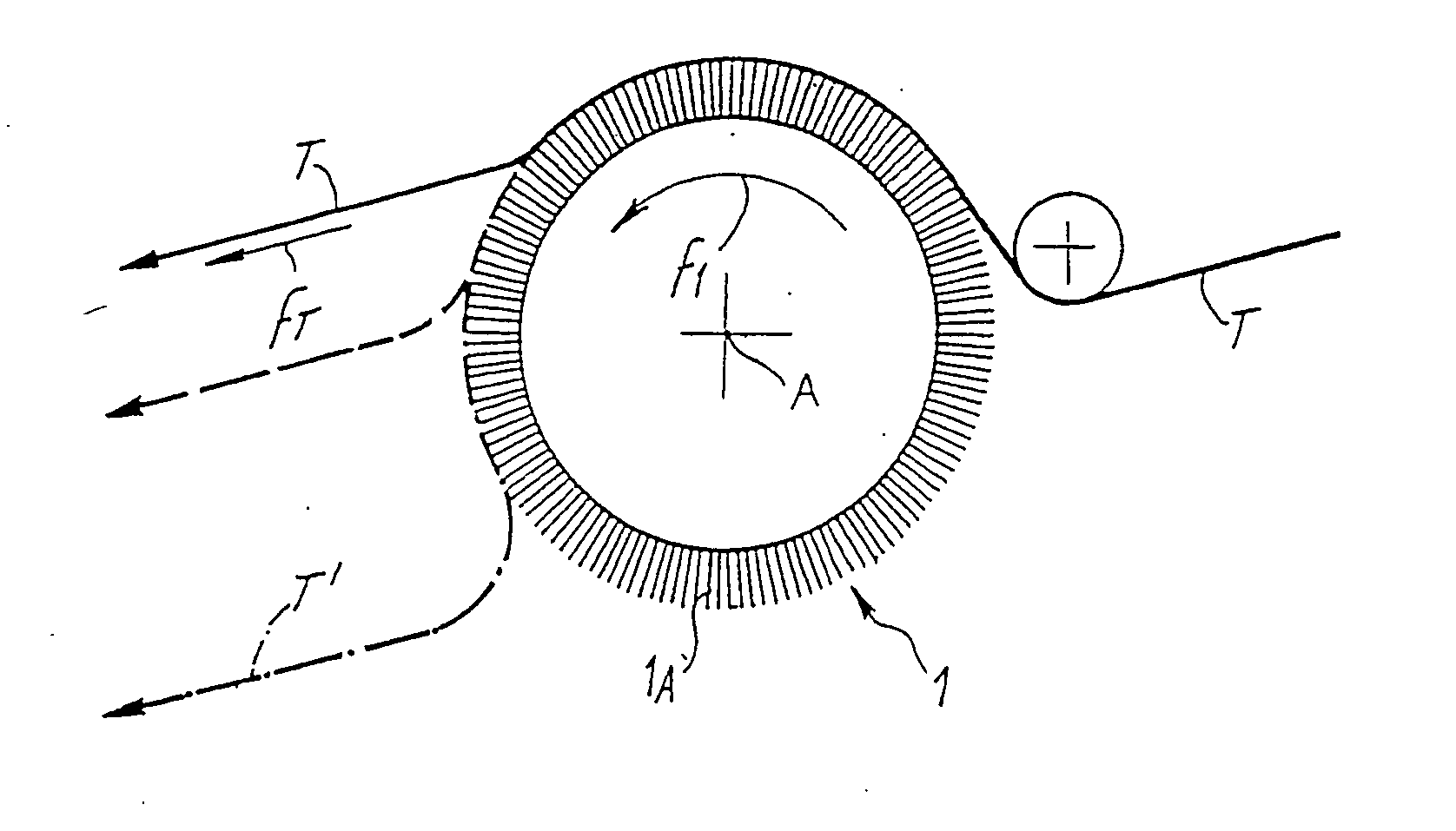

Reference numeral 1 in FIG. 1 very schematically indicates an abrasive rotating cylindrical member, specifically an abrasive cylindrical brush in this example. The cylindrical member turns on an axis A in the direction indicated by the arrow f1. Reference 1A indicates a clothing, for example, made of filaments of synthetic material charged with abrasive particles, e.g. TYNEX® filaments.

A textile fabric T advancing the arrow fT is guided around the rotating cylindrical member 1. As shown in FIG. 1, the trajectory of the fabric T can vary according to the contact arch on the cylindrical member 1. By reducing the tension on the textile fabric T, the latter is dragged downwards by the cylindrical member 1, whose peripheral speed is higher than the speed of advancement of the fabric itself. Excessively low stress on the textile fabric T makes the fabric tend to wind around the rotating cylindrical member 1, as shown by the fabric in the attitude indicated by reference T′.

This proble...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap