Method for making enhanced light transmission conductive coated transparent substrate

a technology of transparent substrate and conductive coating, which is applied in the direction of optical elements, instruments, transportation and packaging, etc., can solve the problems of greater manufacturing time and expense, and achieve the effects of reducing glare, high efficiency, and maximizing light transmission through the coated substra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

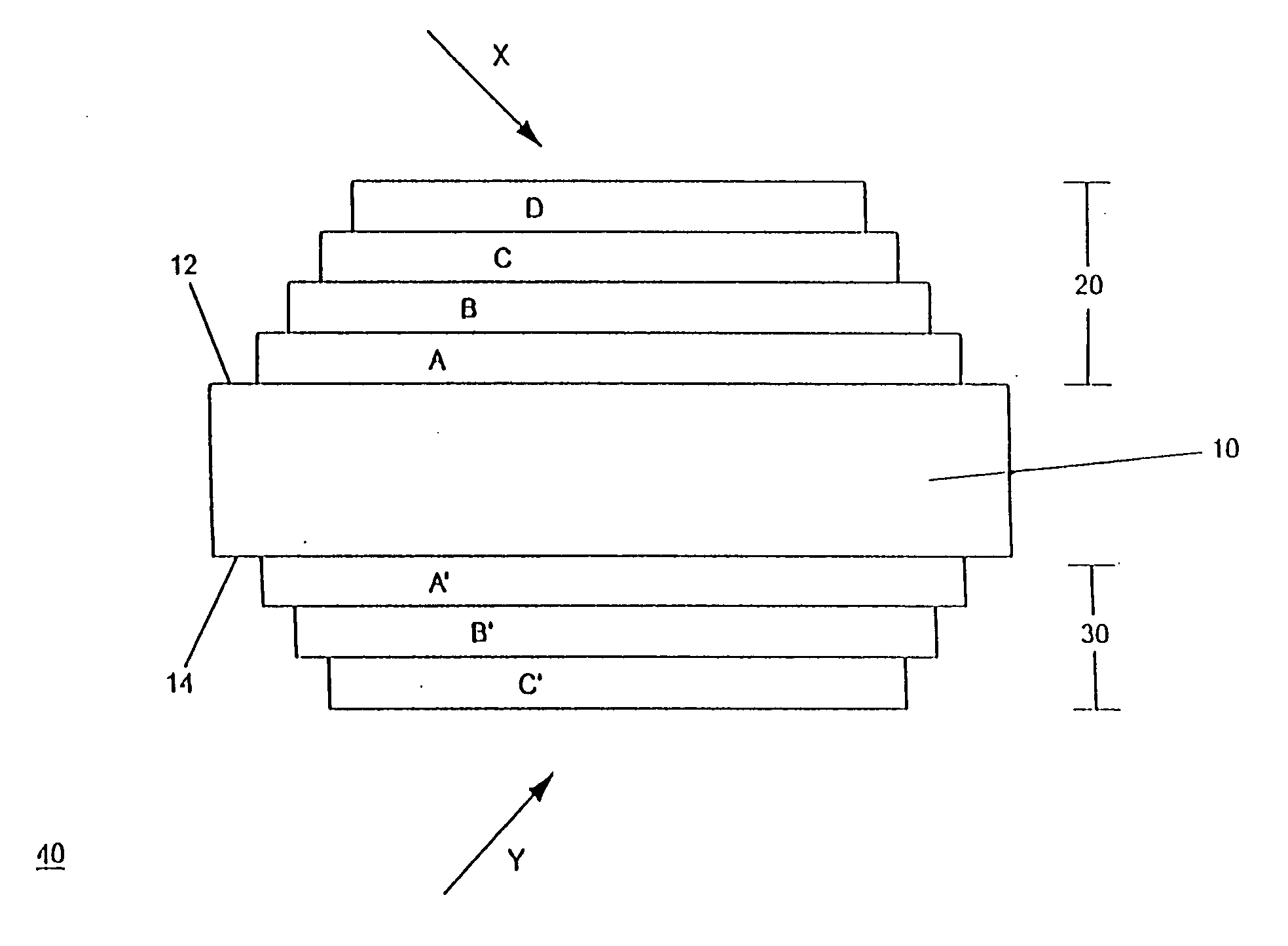

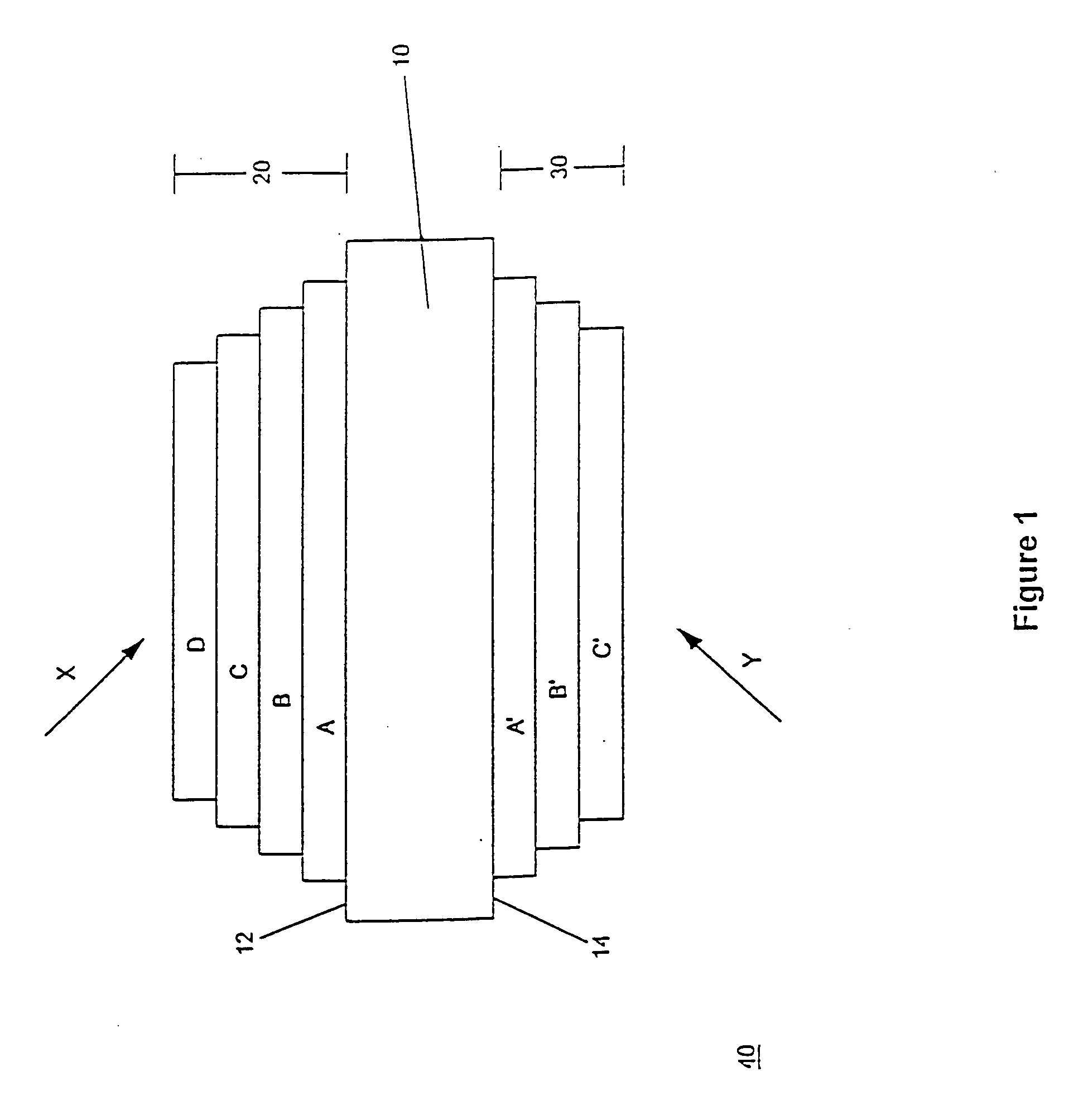

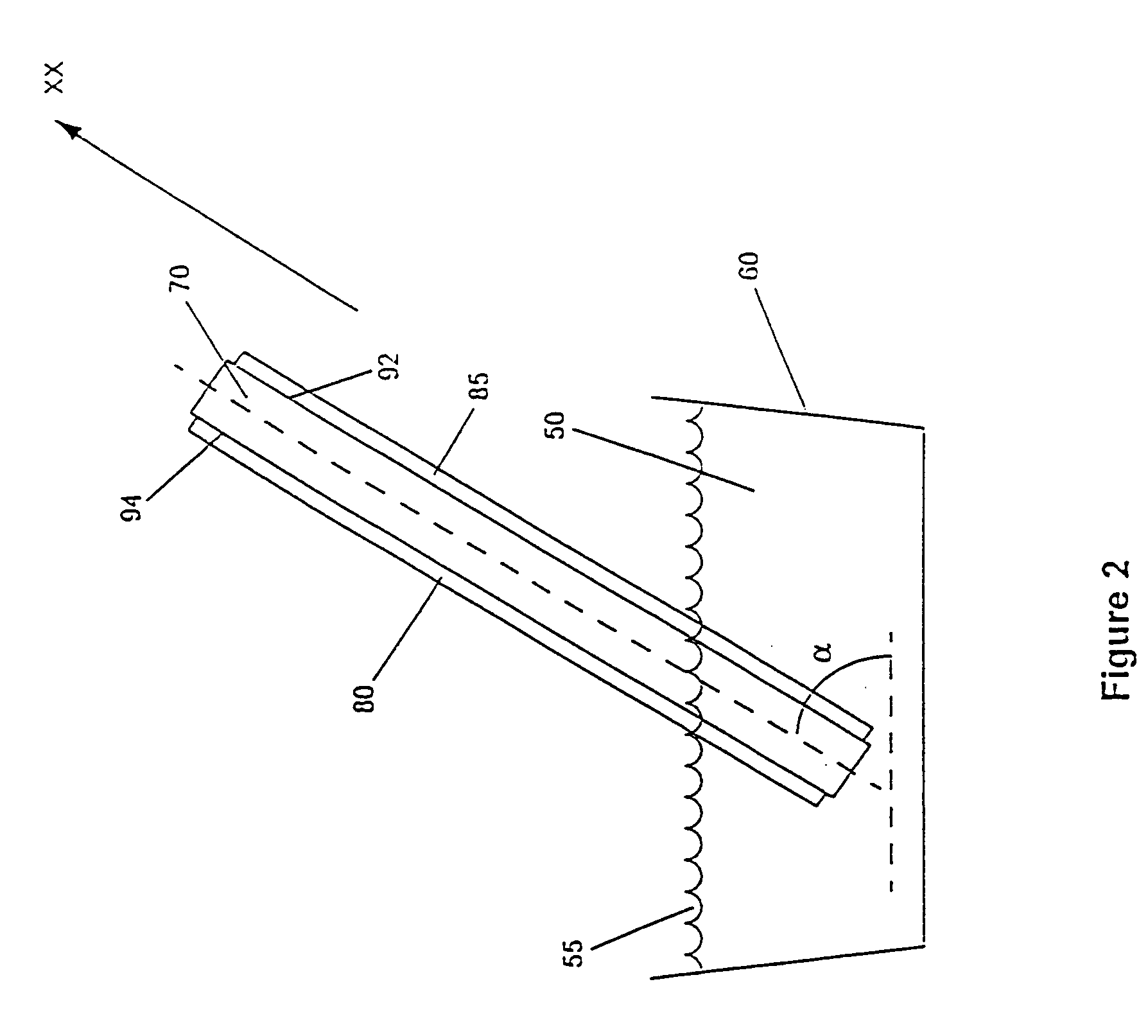

[0022] More specifically, and as shown in FIG. 1, the invention relates to an improved reduced-glare conductive coated panel 40 comprising a substrate 10 such as glass having a first surface 12 and a second surface 14. Optionally, the transparent substrate of the present invention may be an optical plastic comprising a conductively coated cyclic olefin copolymer plastic substrate as disclosed in U.S. provisional patent application Ser. No. 60 / 231,096, filed Sep. 8, 2000, entitled PLASTIC SUBSTRATE FOR INFORMATION DEVICES, the disclosure of which is hereby incorporated by reference herein in its entirety. Such rigid plastic substrate may be formed from a cyclic olefin copolymer (COC) such as is available from Ticona of Summit, N.J., under the trade name “Topas.” Cyclic olefin-containing resins provide an improved material for a rigid, transparent conductively coated substrate suitable for use in an information display. The improved information display incorporating the improved plast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com