Copy-forgery-inhibited pattern density parameter determination method, copy-forgery-inhibited pattern image generation method, and image processing apparatus

a pattern density and parameter determination technology, applied in the field of copyforgery-inhibited pattern density parameter determination, copyforgery-inhibited pattern image generation method, image processing apparatus, can solve the problems of inability to reproduce small dots perfectly on the copy, the copying machine suffers a limitation on image reproduction performance, etc., and achieve the effect of efficient determination of copyforgery-inhibited pattern density parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[First Embodiment]

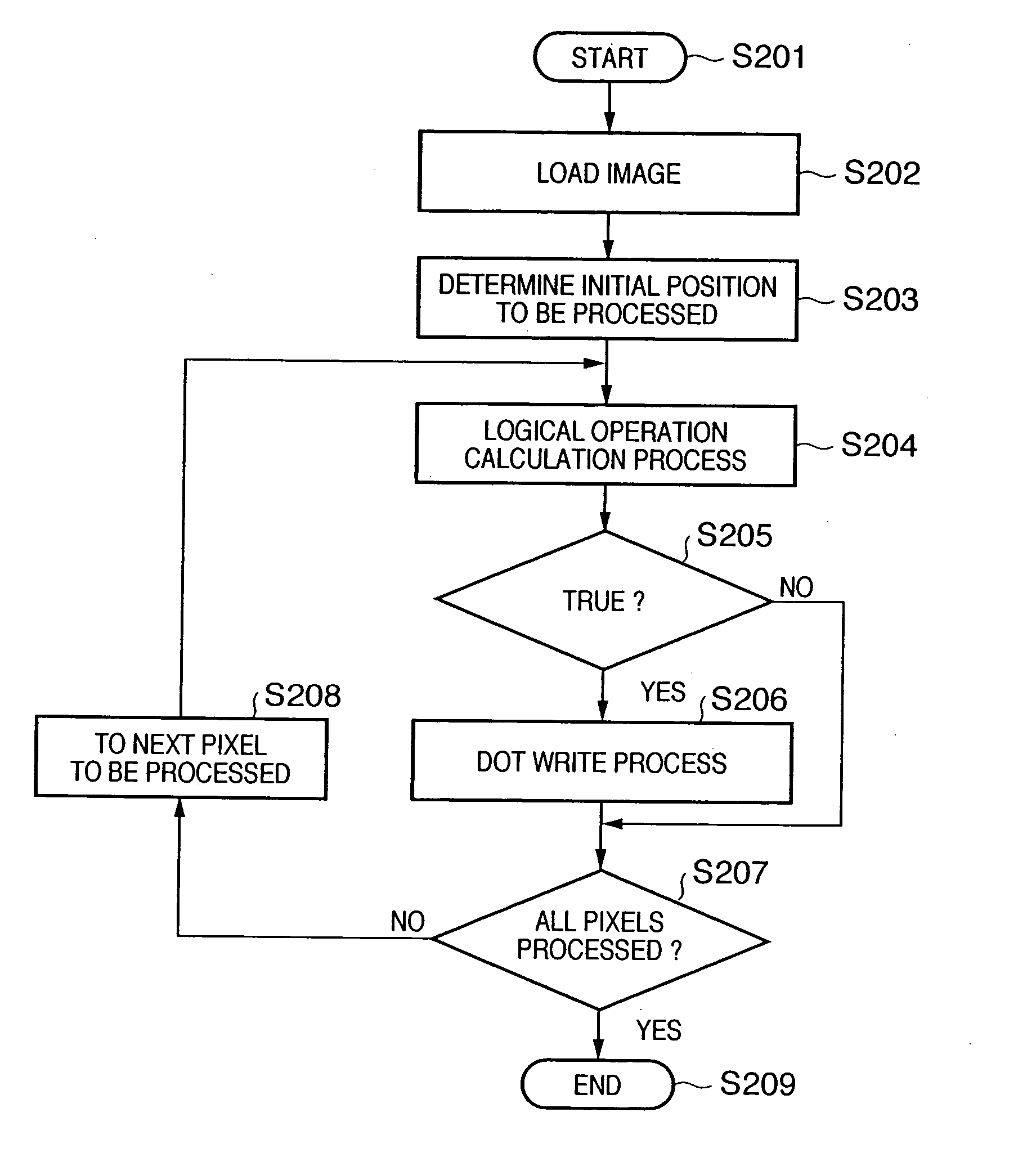

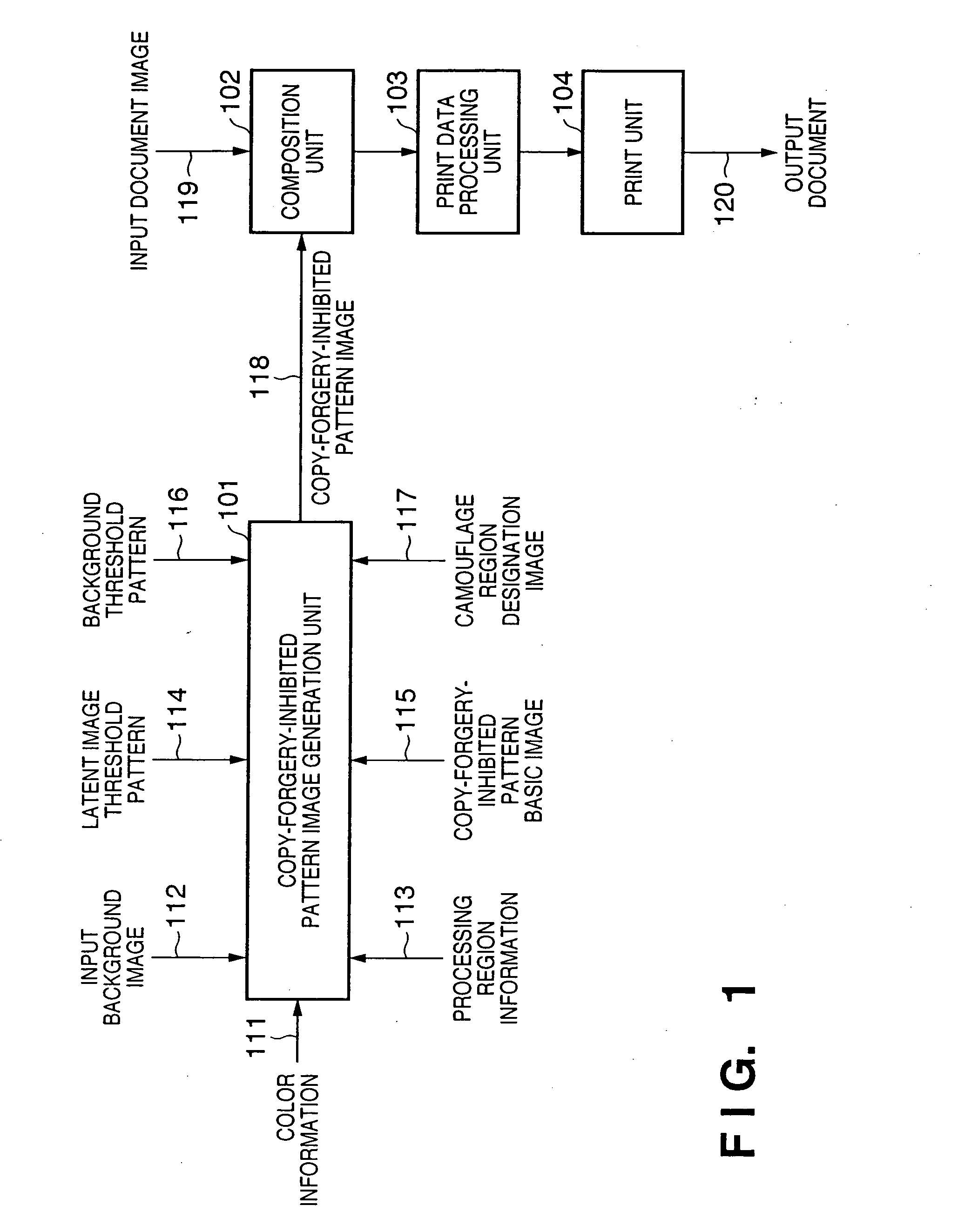

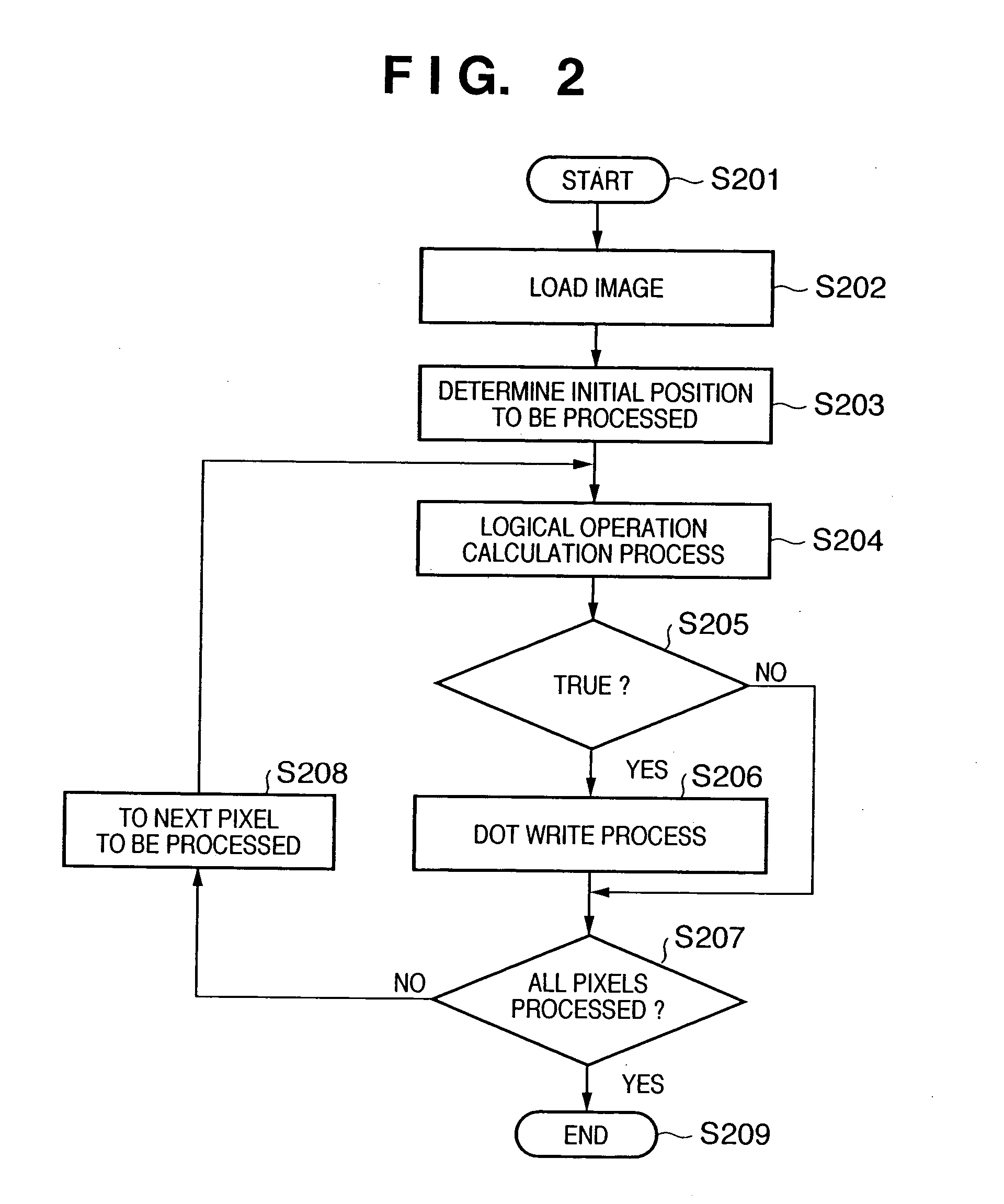

In this embodiment, a combination of a background threshold pattern and latent-image threshold pattern as patterns (binary images) which form the background-image part and latent-image part and can set equal densities for the background-image part and latent-image part upon printing is determined in advance, and logical operations are executed using the background threshold pattern, the latent-image threshold pattern, a copy-forgery-inhibited pattern basic image as a binary image that designates the latent-image part and background-image part, and a camouflage region designation image as a binary image that designates a camouflage region, thereby generating a copy-forgery-inhibited pattern image at high speed using a small memory size.

Note that the background threshold pattern and latent-image threshold pattern are parameters that determine the densities of the background-image part and latent-image part of a copy-forgery-inhibited pattern image upon printing, a...

second embodiment

[Second Embodiment]

The second embodiment according to the present invention will be described in detail hereinafter with reference to the accompanying drawings. In the second embodiment, respective processes described in the first embodiment are implemented by a computer.

FIG. 25 is a block diagram showing the basic arrangement of a computer in the second embodiment. For example, when this computer executes all the functions except for the print unit (or the printer engine of the print unit) in FIGS. 1, 15, 22, and 23 in the first embodiment, the respective functions are expressed by a program, which is loaded by this computer, thus implementing all the functions except for the print unit (or the printer engine of the print unit) in FIGS. 1, 15, 22, and 23 in the first embodiment.

Referring to FIG. 25, reference numeral 2511 denotes a CPU which controls the overall computer, and executes respective processes described in the first embodiment using programs and data stored in a RAM...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com