Sample warper with idle running preventing mechanism of yarn guide

a technology of preventing mechanism and yarn guide, which is applied in the direction of manufacturing tools, electric/magnetic/electromagnetic heating, beaming machines, etc., can solve the problems of increasing the ratio of total idle running time of the yarn guide during yarn exchanging to the warping operation time, and the time disadvantageously required for a warping operation, so as to reduce the time of warping operation and improve the speed of yarn exchanging remarkably. , the effect of preventing the speed o

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will be explained below with reference to the attached drawings. It is apparent that the present invention will be modified variously from the illustrated embodiments without departing from the technical idea of the present invention.

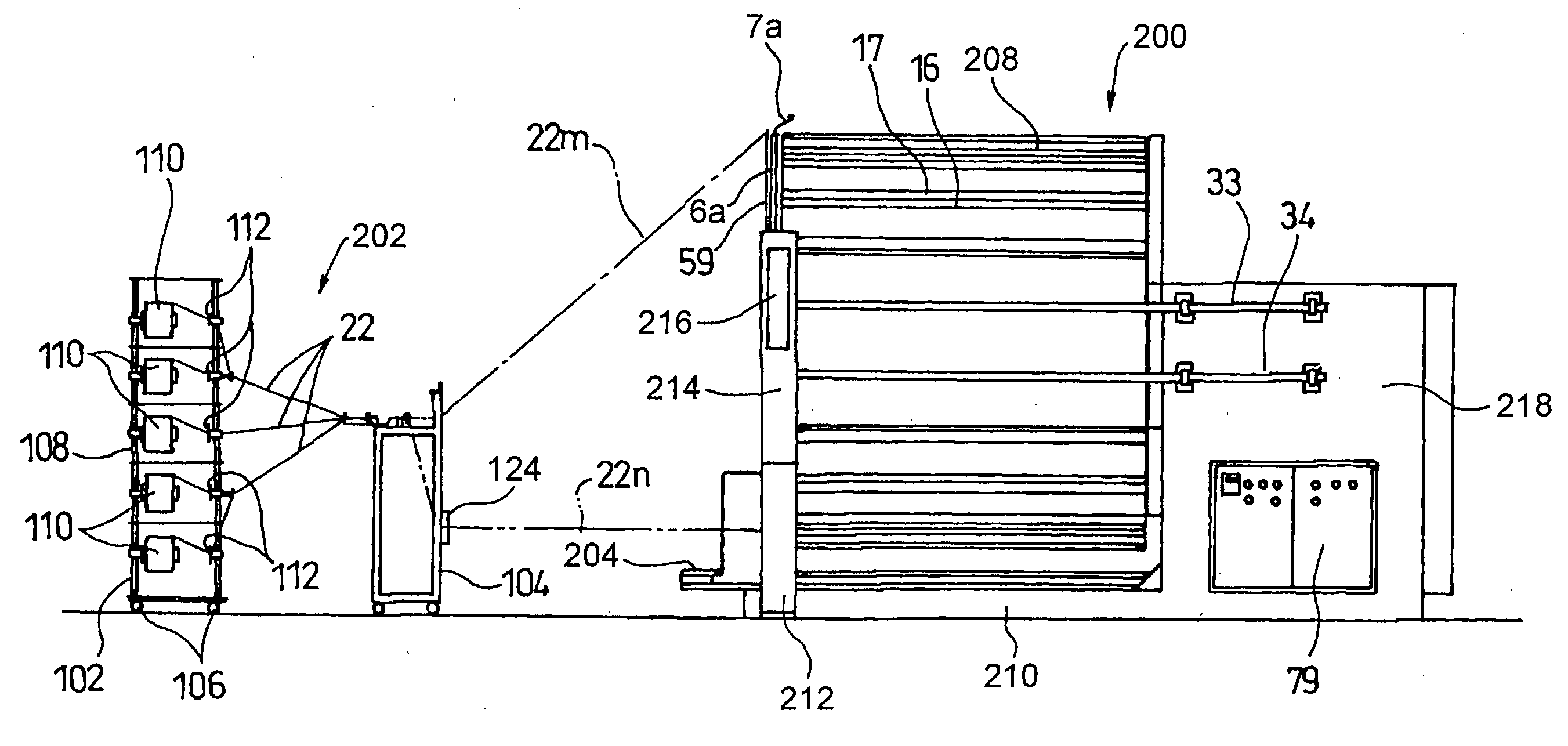

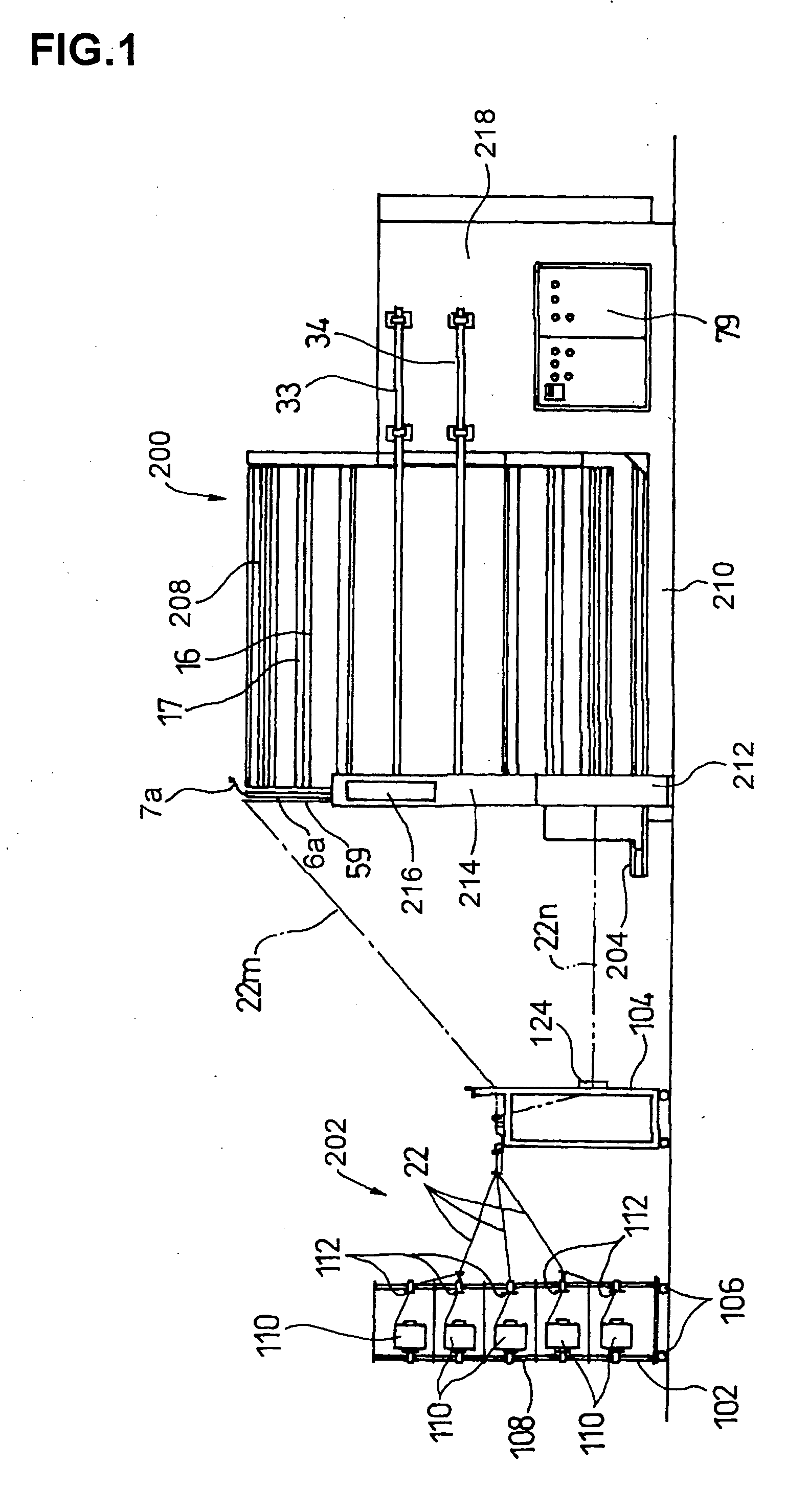

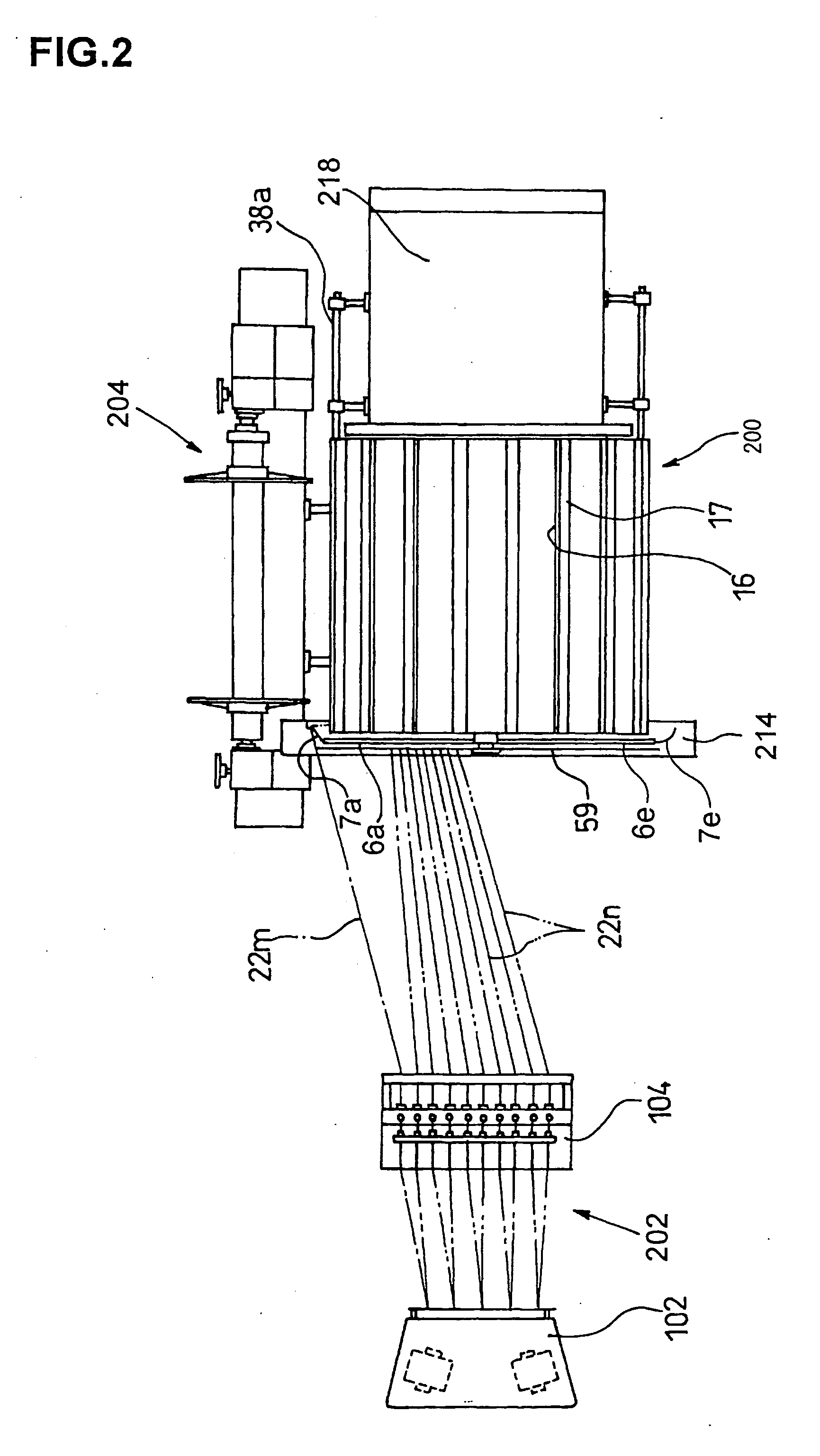

[0034] In FIGS. 1 to 3, reference numeral 200 denotes a sample warper according to the present invention that has a basic structure and function in common with the conventional sample warper except for a characteristic structure and function according to the present invention, which will be described later.

[0035] As illustrated, like the above-described conventional sample warper, the sample warper 200 of the present invention comprises a plurality of yarn guides 6a to 6h (the number of the yarn guides is not limited to a specific number, but eight of the yarn guides are shown in the illustrated embodiment), each of which is rotatably mounted on a side surface of a warper drum 208 for winding yarns 22 on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| idle running time | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com