Dual propeller drive for ski boat

a technology for ski boats and propellers, which is applied in the direction of propulsive transmission, marine propulsion, and can solve the problems of increasing the cost of ski boats, requiring greater power, and heavy boats such as 28-foot boats, and achieves the effects of not reducing the maximum speed reducing the weight of the ski boat, and increasing the pulling power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

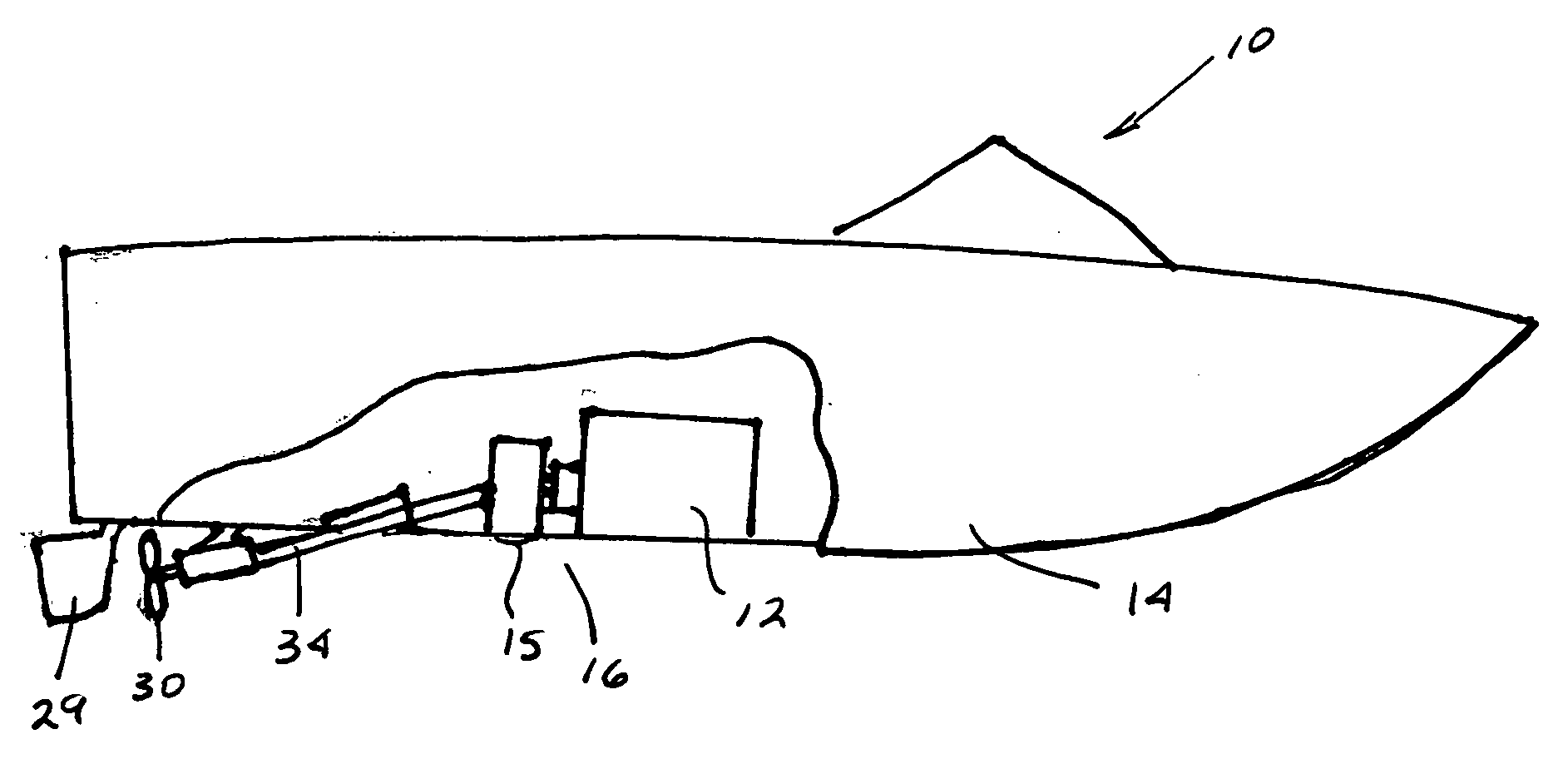

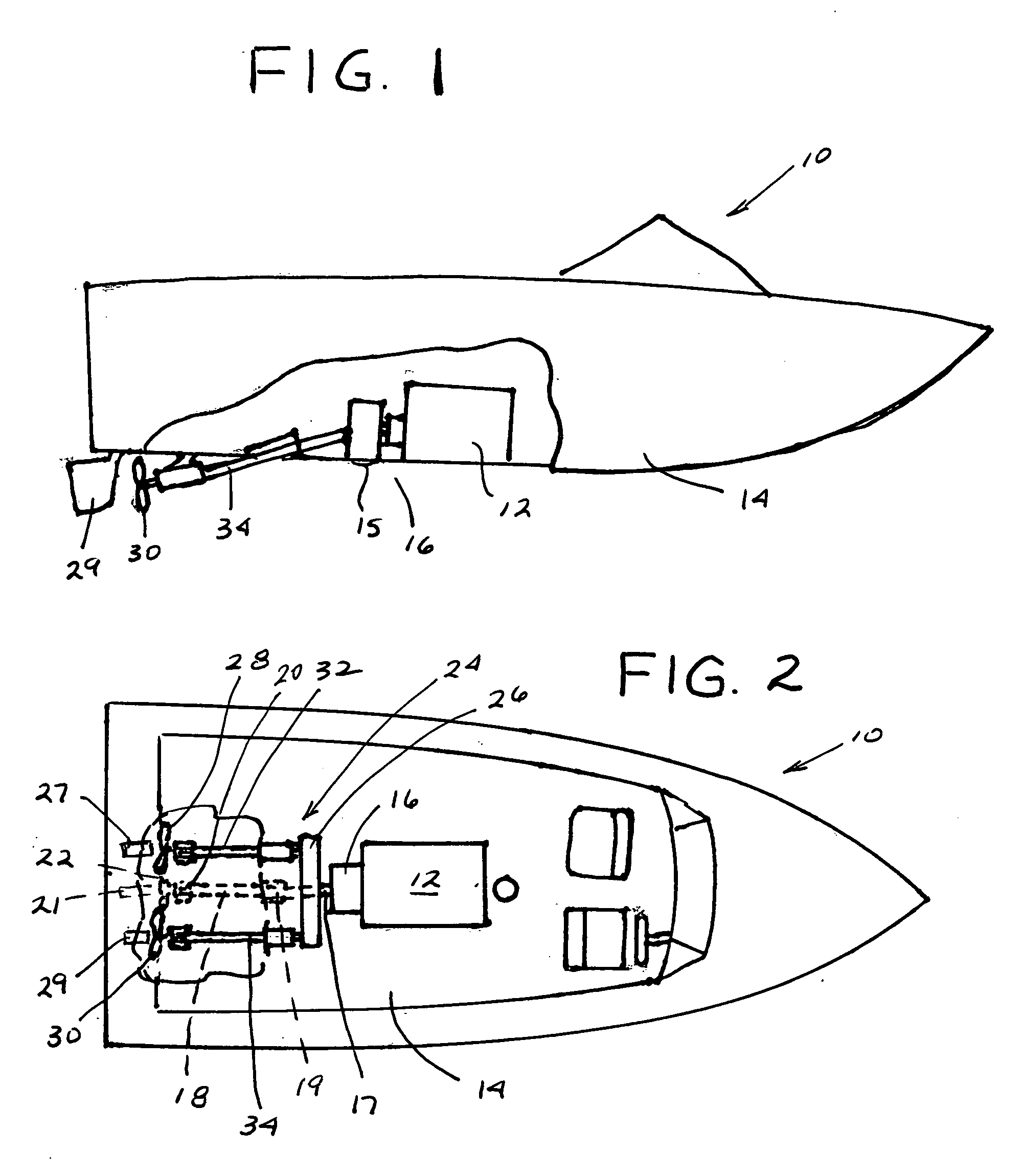

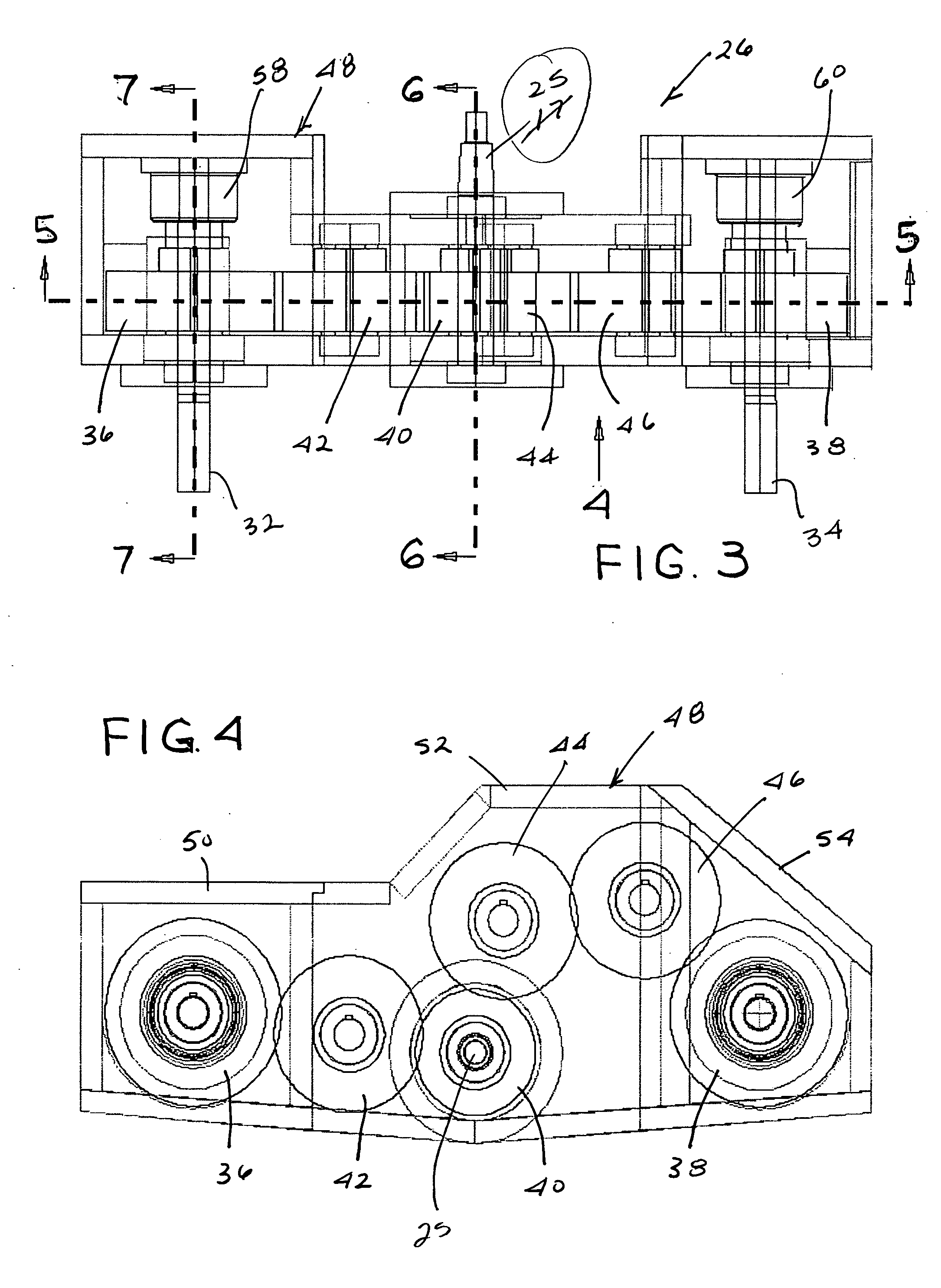

[0021] A motor boat or powerboat 10, shown schematically, includes an inboard engine 12, such as a 350 horsepower automobile engine or larger, mounted in a conventional manner inside the hull 14 of the boat. The engine has a conventional transmission 16, which typically permits the engine to be shifted between neutral, forward, and reverse gears. In the exemplary embodiment the engine transmission includes a gear reduction ratio of 1½ to 1, which means that when the engine is rotating at 3,000 rpm, the engine output shaft is rotating at 2,000 rpms.

[0022] A conventional inboard engine (which for convenience will be deemed to include the conventional engine transmission) drives the boat by means of a propeller shaft 18, which extends downwardly and rearwardly from driving engagement with an output shaft 17 of the engine through the bottom of the boat to an outer end, on which a propeller is mounted. The propeller shaft is journalled in seal 19 in the floor of the boat and in a suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com