Container refilling system

a refilling system and container technology, applied in the direction of transportation and packaging, liquid handling, packaging goods types, etc., can solve the problems of inconvenient refilling, messy refilling process, frustration of many consumers, etc., to reduce messiness and dripping, reduce the overall refilling experience, and reduce the effect of messiness and dripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

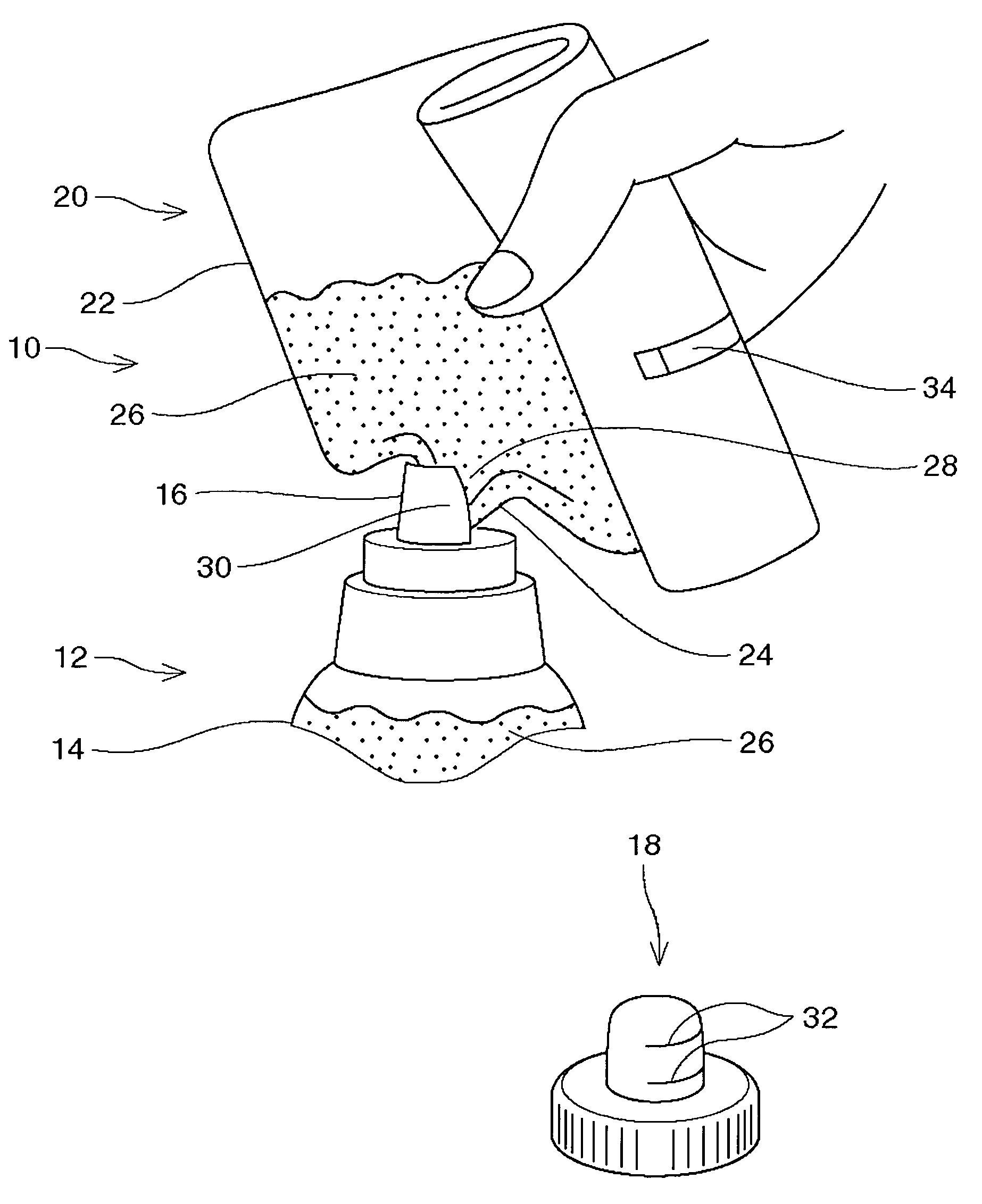

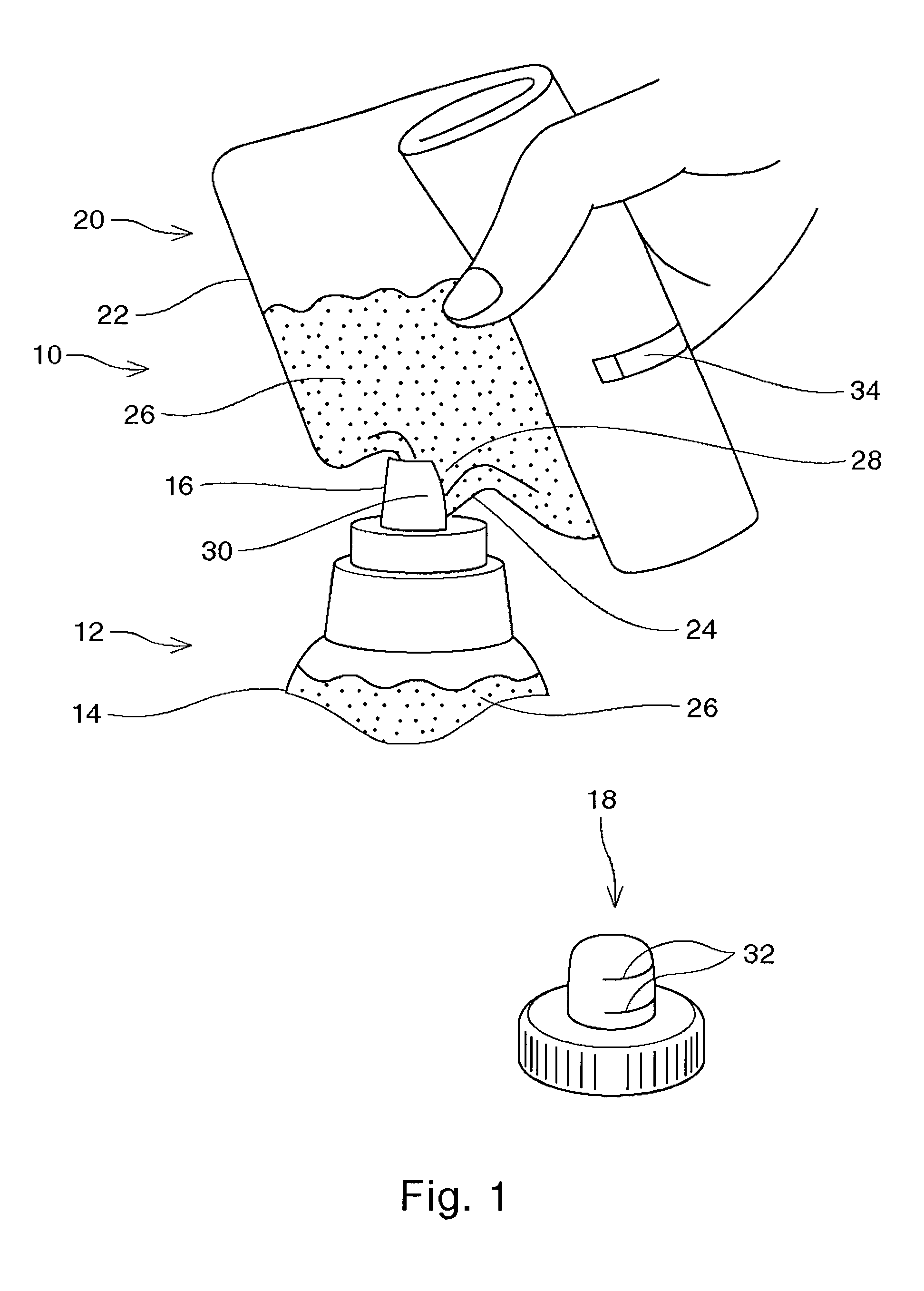

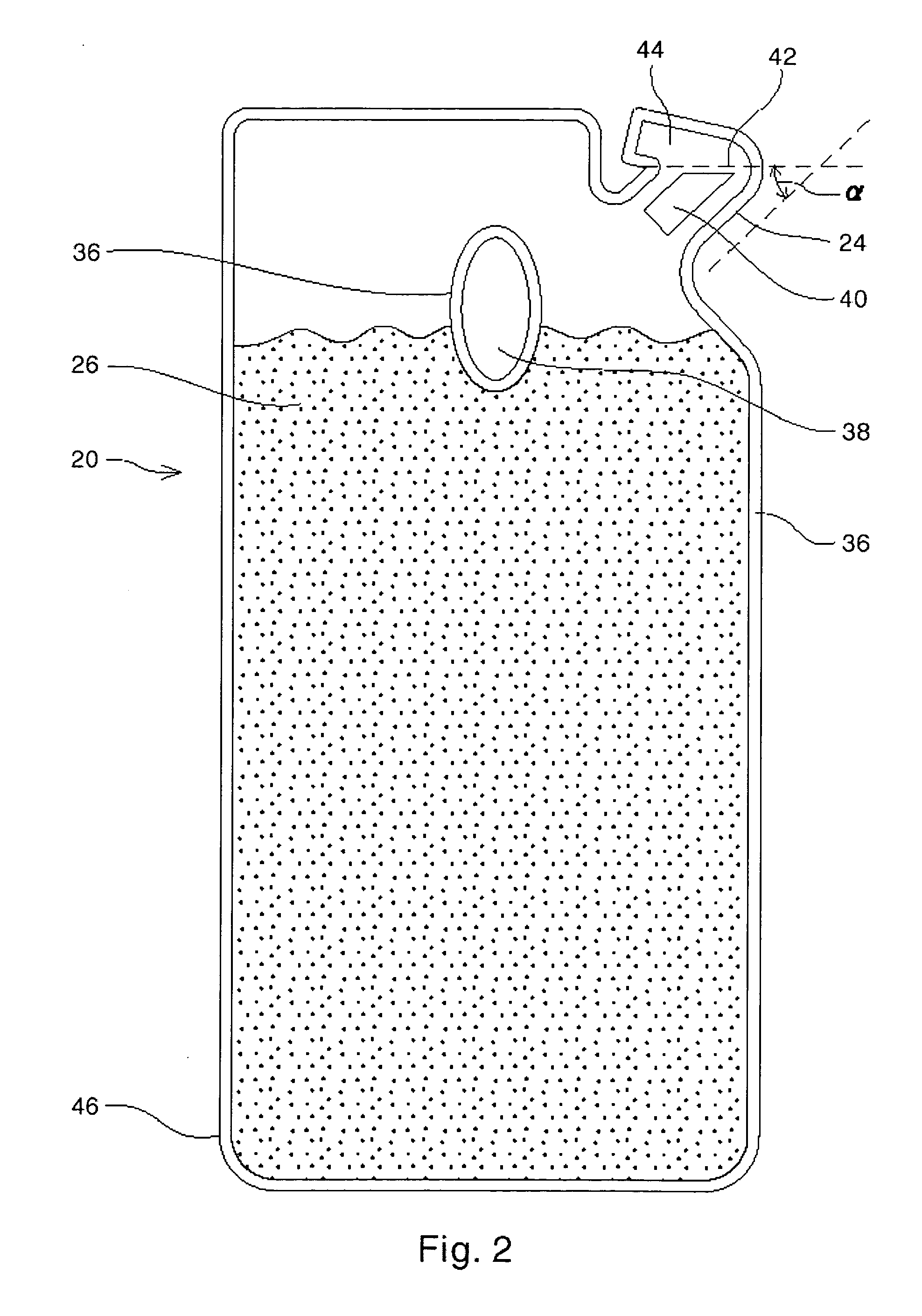

[0028] A refilling system as in FIG. 1 is provided, employing the refilling container of FIG. 2. The container is formed from blow molded polypropylene, and the refilling container is formed of a 155μ thick laminated film containing nylon (25μ) / linear low density polyethylene (130μ). A semi-rigid polyethylene tube is present in the refilling spout. The refilling container contains a clear fabric softening composition.

[0029] The refilling spout has an exterior surface which is generally an oval having a minimum diameter of about 9 mm and a maximum diameter of about 12 mm. The interior surface of the pouring spout is also generally an oval having a minimum diameter of about 12 mm, and a maximum diameter of about 18 mm. Thus, the refilling spout and even the seal edges of the refilling spout fit easily into the pouring spout during use of the refilling system to pour the composition into the container, and the hollow bottle.

[0030] An instruction set is provided on the back of the ref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com