Knockdown furniture assembly and method for making same

a furniture and knocking technology, applied in the field of furniture assembly, can solve the problems of furniture becoming unstable and ultimately unusable, and achieve the effect of convenient reassembling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

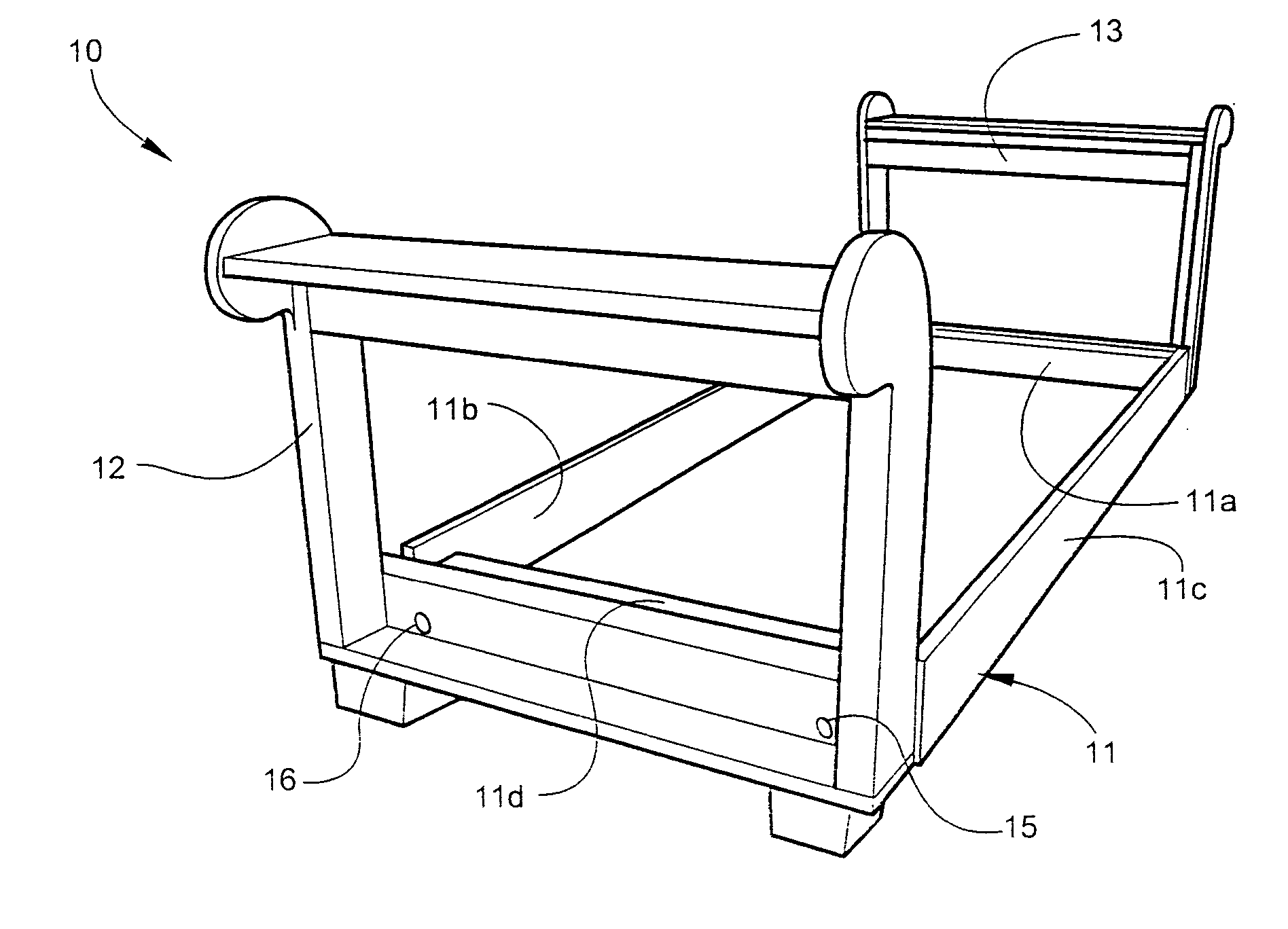

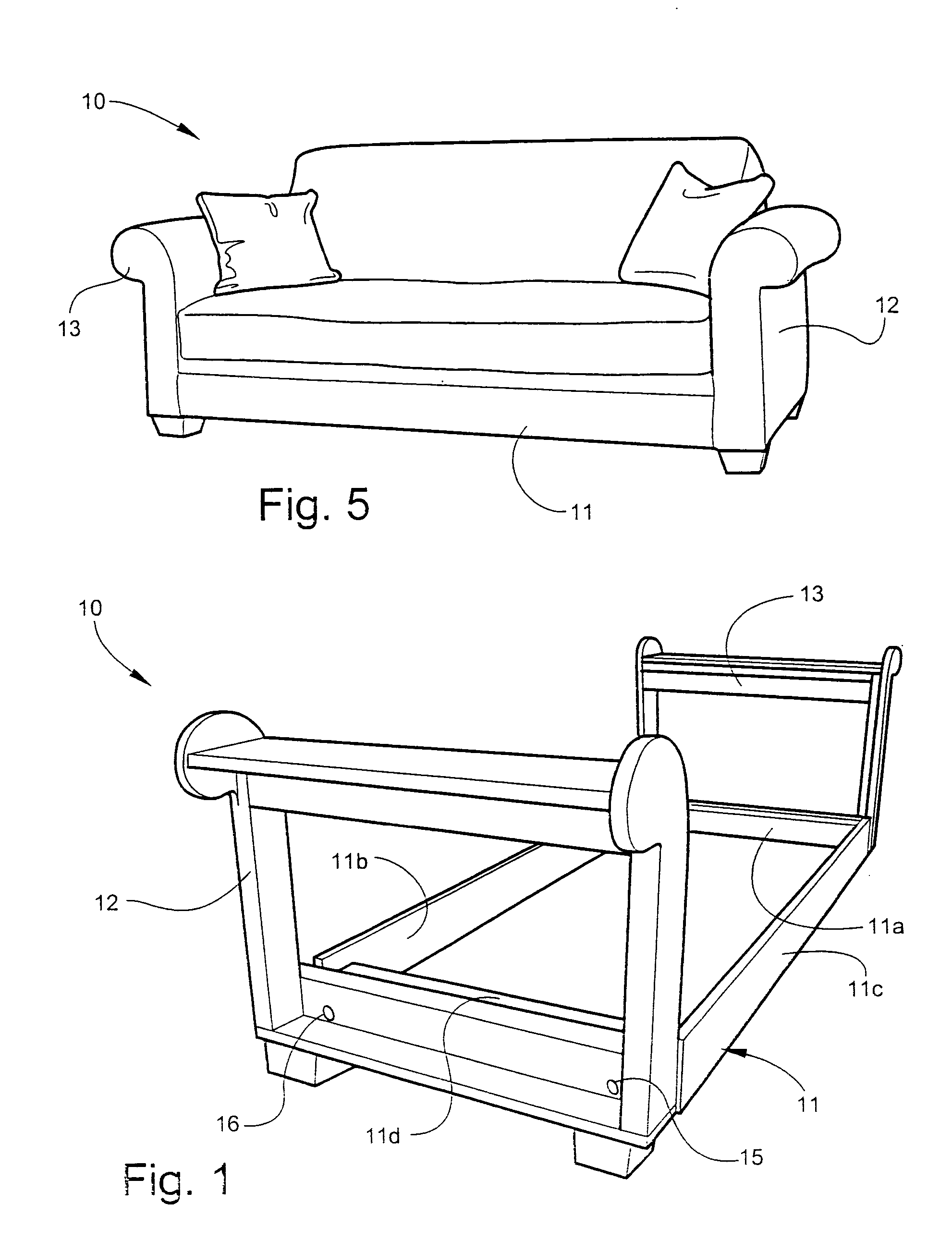

[0032] Referring now specifically to the drawings, a preferred embodiment of the knockdown furniture assembly according to the present invention is illustrated in FIG. 1, and shown generally at reference numeral 10. The furniture assembly 10 generally comprises a frame 11 releasably connected to two arm pieces 12, 13. The frame 11 is preferably rectangular with sides 11a-d, and the arm pieces 12, 13 are positioned on opposite sides 11a, 11d of the frame 11. The frame 11 and arm pieces 12, 13 are preferably made of wood.

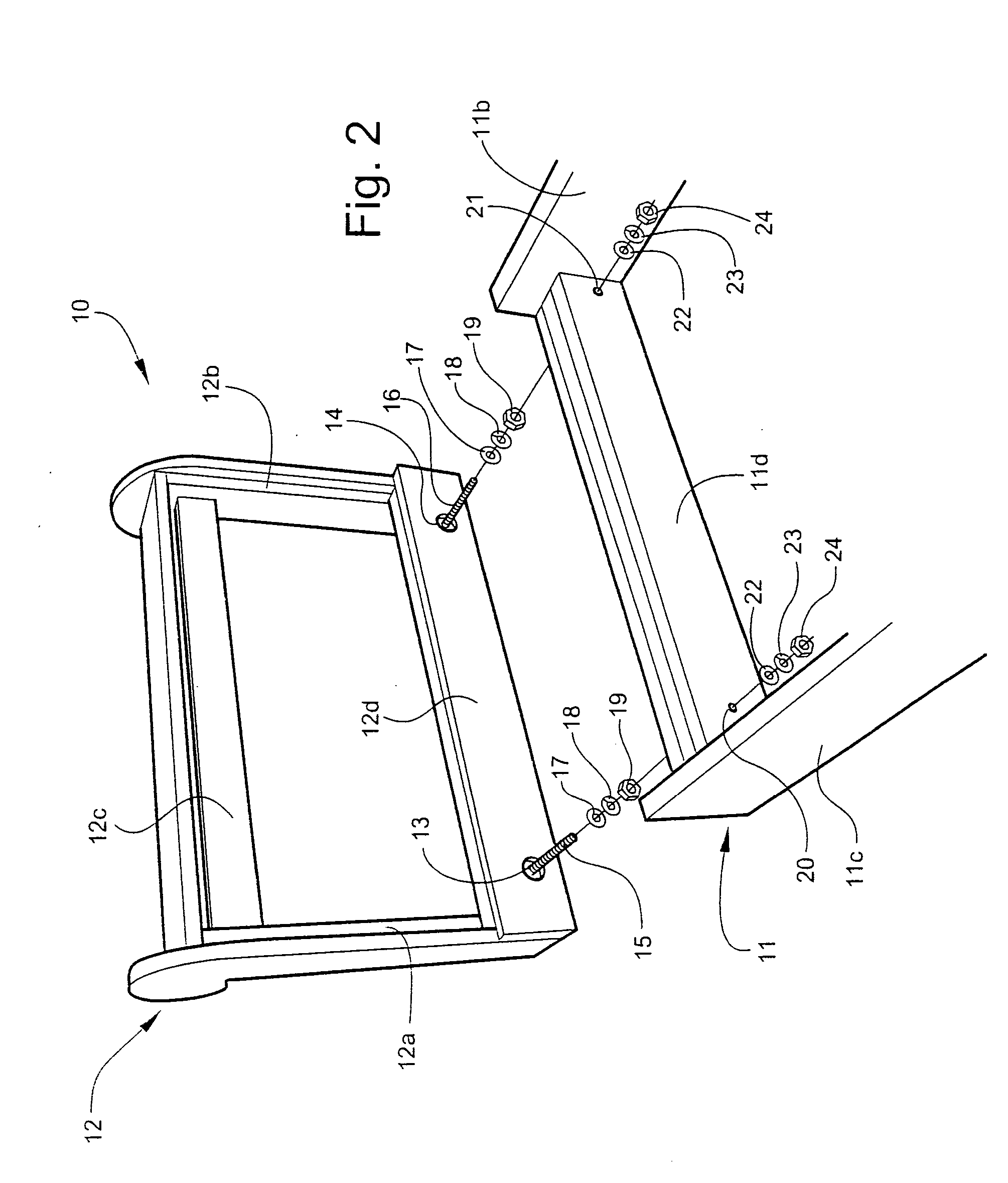

[0033] Each arm piece 12, 13 is identical, and therefore, only one arm piece 12 will be described in detail. As shown in FIG. 2, arm piece 12 comprises two vertical members 12a, 12b, joined together by a horizontal top rail 12c, and a double bottom rail 12d. Two holes 13, 14 are formed in the bottom rail 12d of the arm piece 12. Carriage bolts 15, 16 are inserted into the holes 13, 14, and fastened to the rail 12d by tightening suitable fasteners, such as flat washer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com