Cleaning pad and cleaning implement

a technology of cleaning implements and cleaning pads, which is applied in the direction of carpet cleaners, cleaning equipment, cleaning machines, etc., can solve the problems of requiring the inconvenience of performing one or more cleaning steps, affecting the cleaning effect, and requiring significant soil redeposition, so as to reduce the effect of drippag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

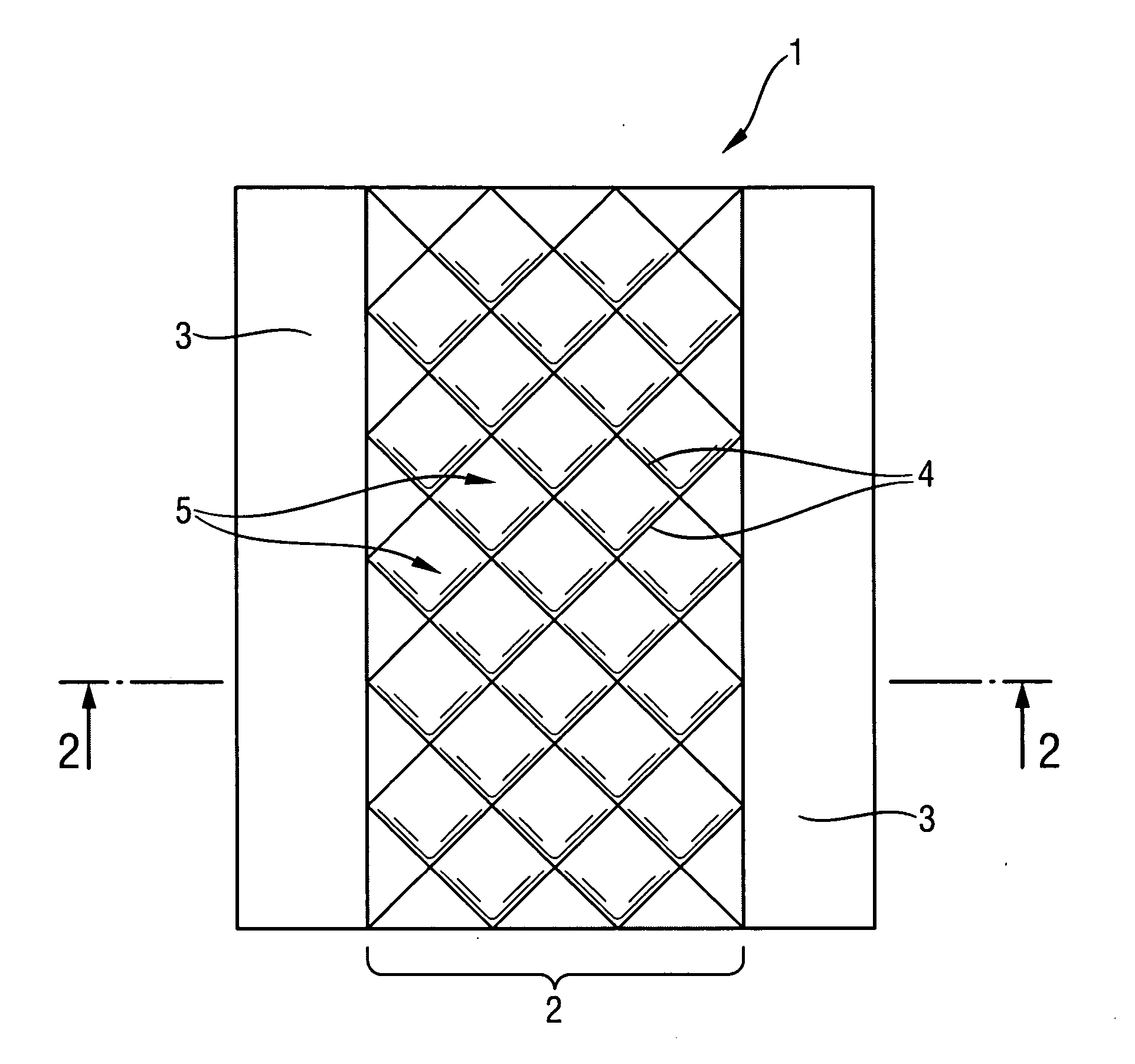

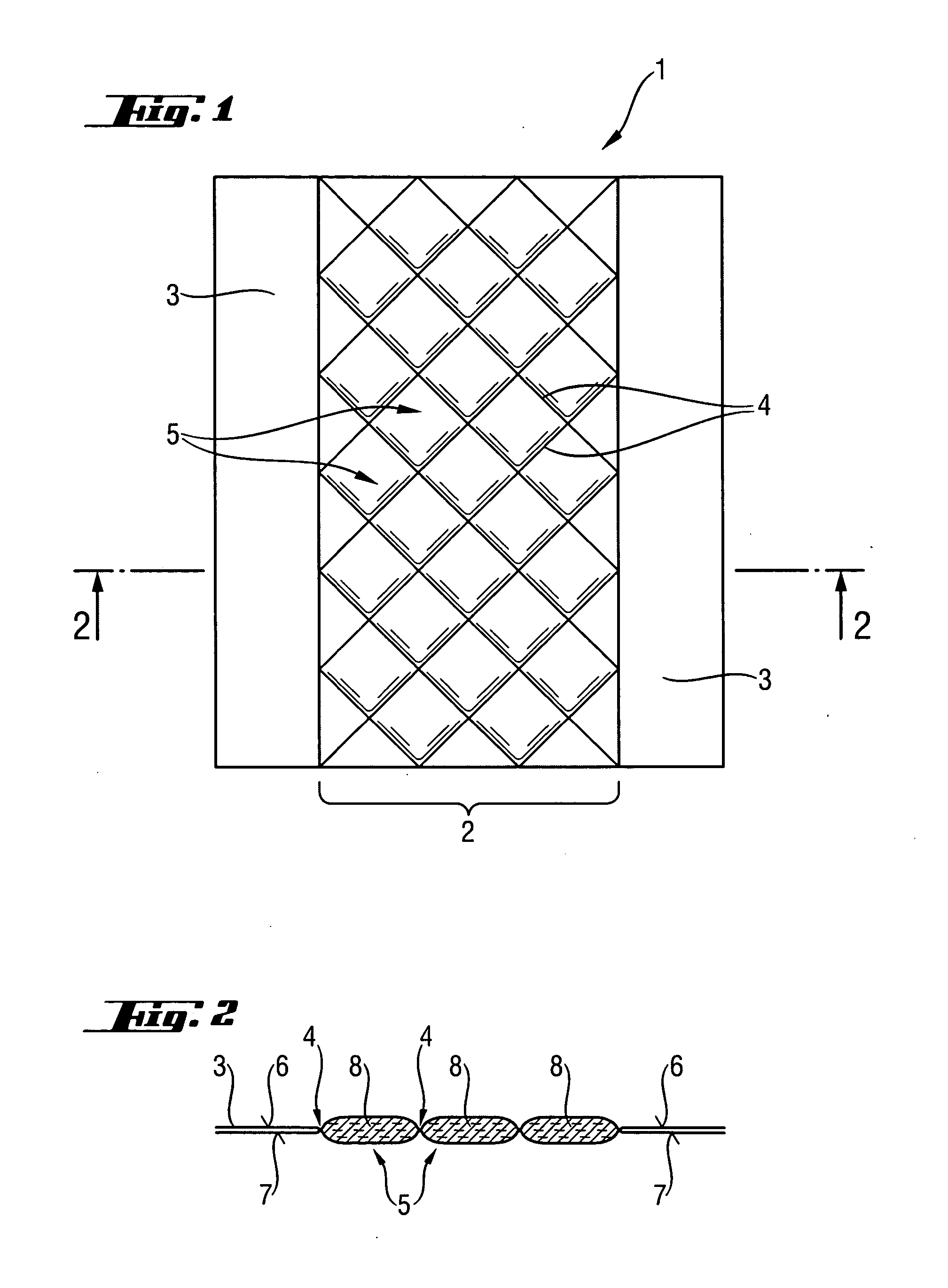

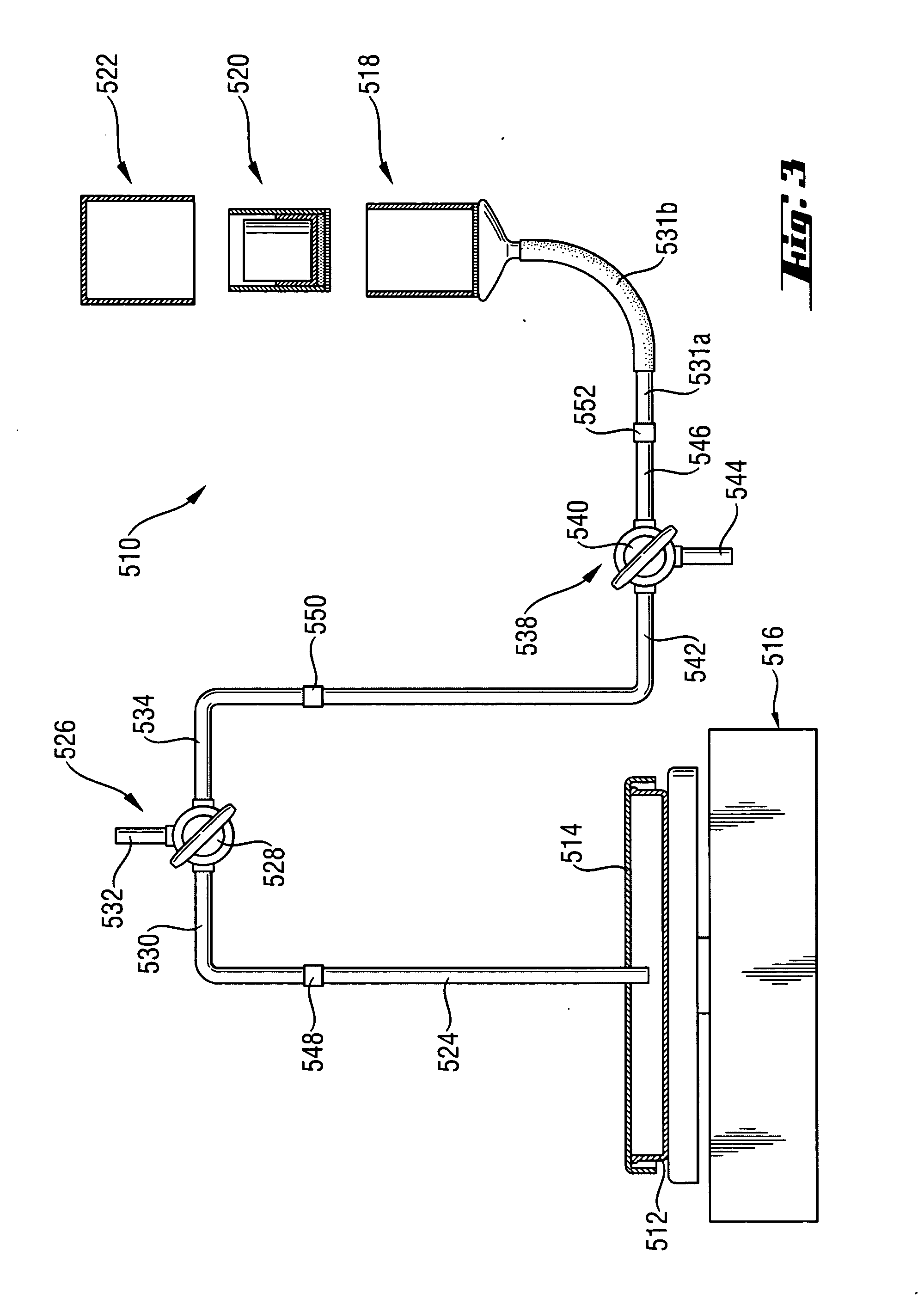

Two dry Swiffer Wet® pads were bonded throughout their thickness, one pad to comprise a plurality of adjacent diamond-shaped reservoirs (as shown in FIG. 1), and the other pad to have a wave pattern extending along the length of the pad, and which does not define discrete fluid reservoirs. (The wave pattern applied was obtained by scanning a Pledge Grab-It Wet pad). The pads were bonded by the following ultrasonic method:

Equipment Used

1. Branson Ultrasonic unit Model 900 BCA 2. 9″ Carbide Horn 3. Magnesium Photo engraved patterned plate 4. Woven Teflon

Process Conditions 1. Amplitude is set to >50% 2. Horn pressure is 30 psig 3. Speed on this particular unit is set to 4 on the dial. This gauge does not give a specified fpm. 4. The gap between the pattern and the horn is set to zero. A piece of woven Teflon material is placed between the horn and the pattern to provide less friction between the two as the pattern moves past the horn.

Steps to Make an Ultrasonically Bond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com