Display devices

a technology of projection optics and micro-machined parts, applied in the direction of picture reproducers, identification means, instruments, etc., can solve the problems of cumbersome and expensive projection optics in relation to transmissive projection optics, loss generation of such devices, and cost and performance limitations of each devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

General Structure of the Panels

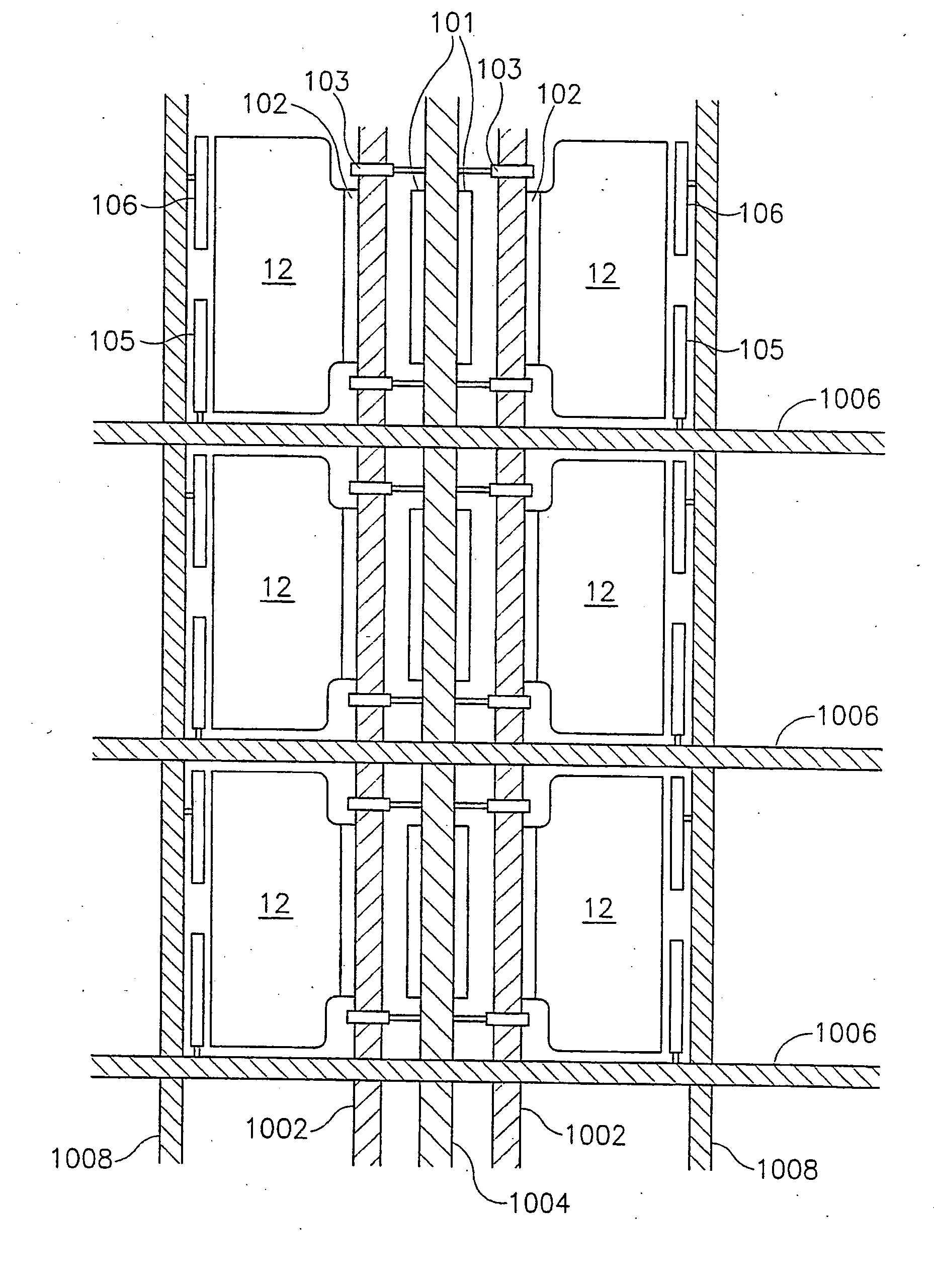

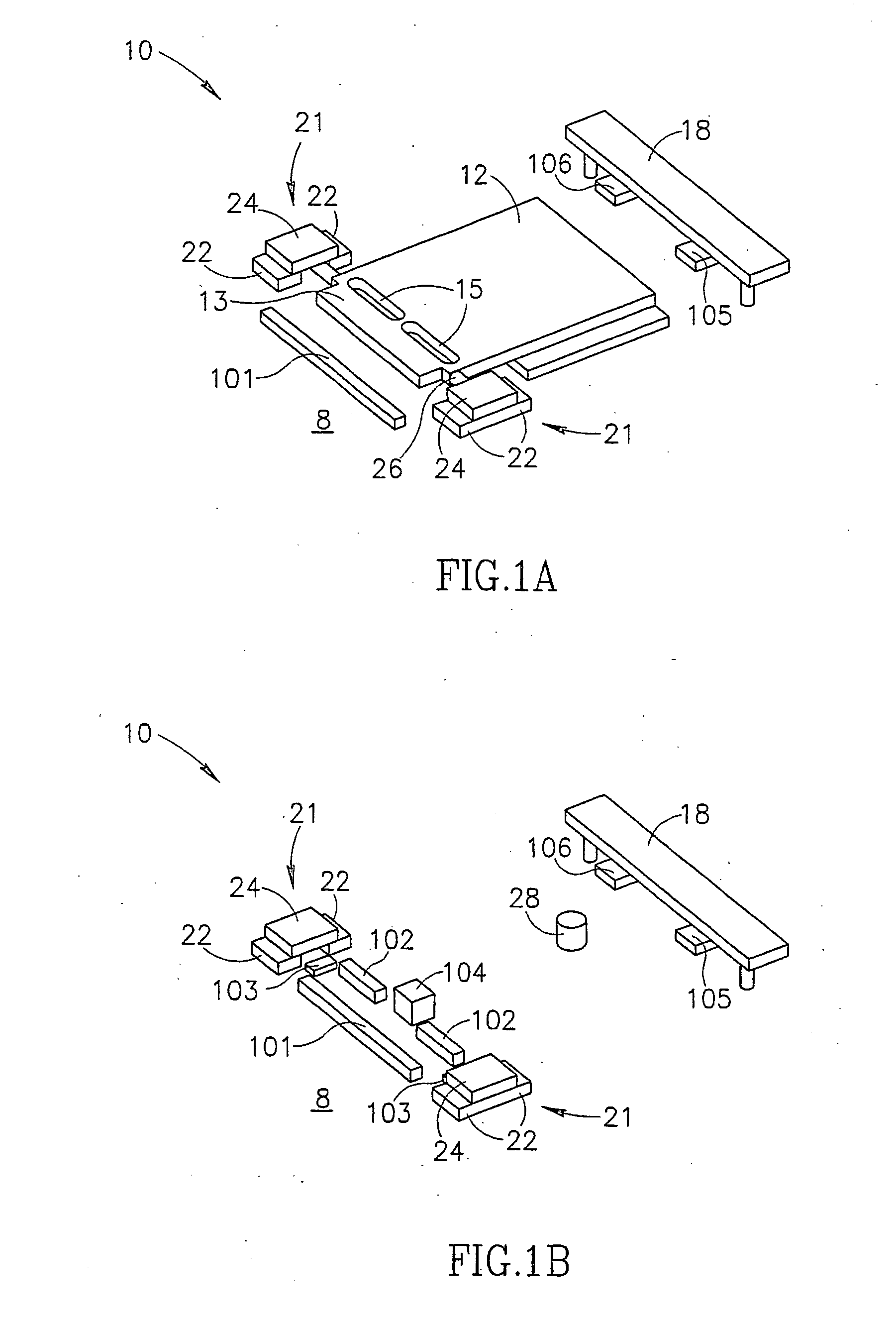

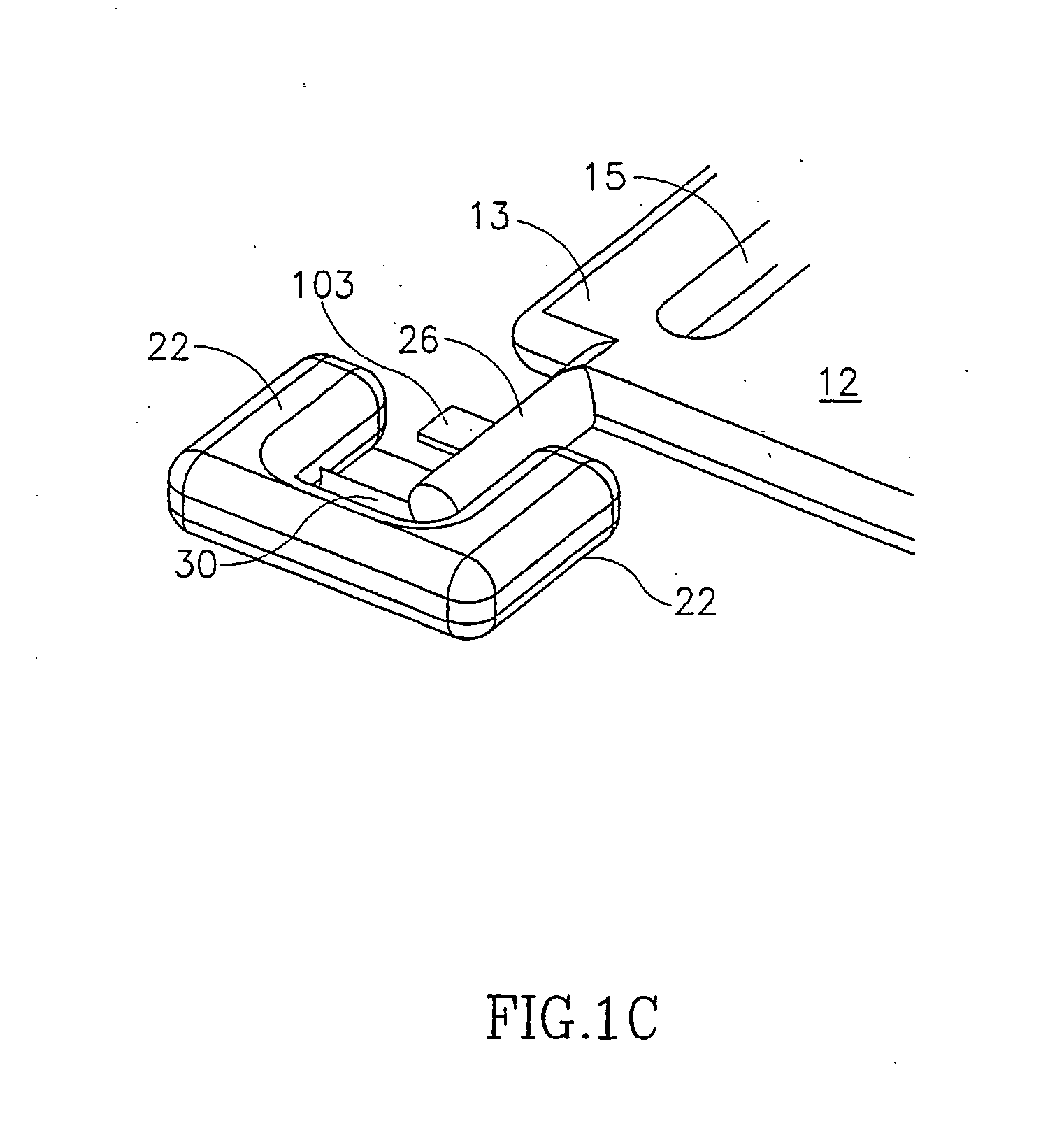

[0086]FIGS. 1A-1D show an overview of an exemplary pixel 10, in accordance with an embodiment of the invention. While this construction is presented as an example, many of the elements shown can have a different construction and some may be deleted altogether.

[0087] Pixel 10 comprises as its major components a flipping panel 12, closing electrode 101, opening electrode 102, clutch electrodes 103, stopping nub 104, row locking electrode 105, column locking electrode 106, levitation electrode 18 and a pair of sockets 21. The panels are formed with preferably rounded axles 26, which fit into sockets 21. The sockets comprise a lower, optionally wedge shaped, element 30 (sometimes referred to herein as a “knife 30”) formed with an upper edge on which the related axle rolls, a pair of side motion constraints 22 and an upper constraint 24. Each electrode is optionally formed with an optionally insulated nub 28 which minimizes the area of contact between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com