Compression bone staple, apparatus and method

a bone segment and compression bone technology, applied in the field of compression bone segment staples, can solve the problems of difficult manual installation of the clip using hemostats and the like, large surgical openings, and inconvenient handling, and achieve the effect of quick application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

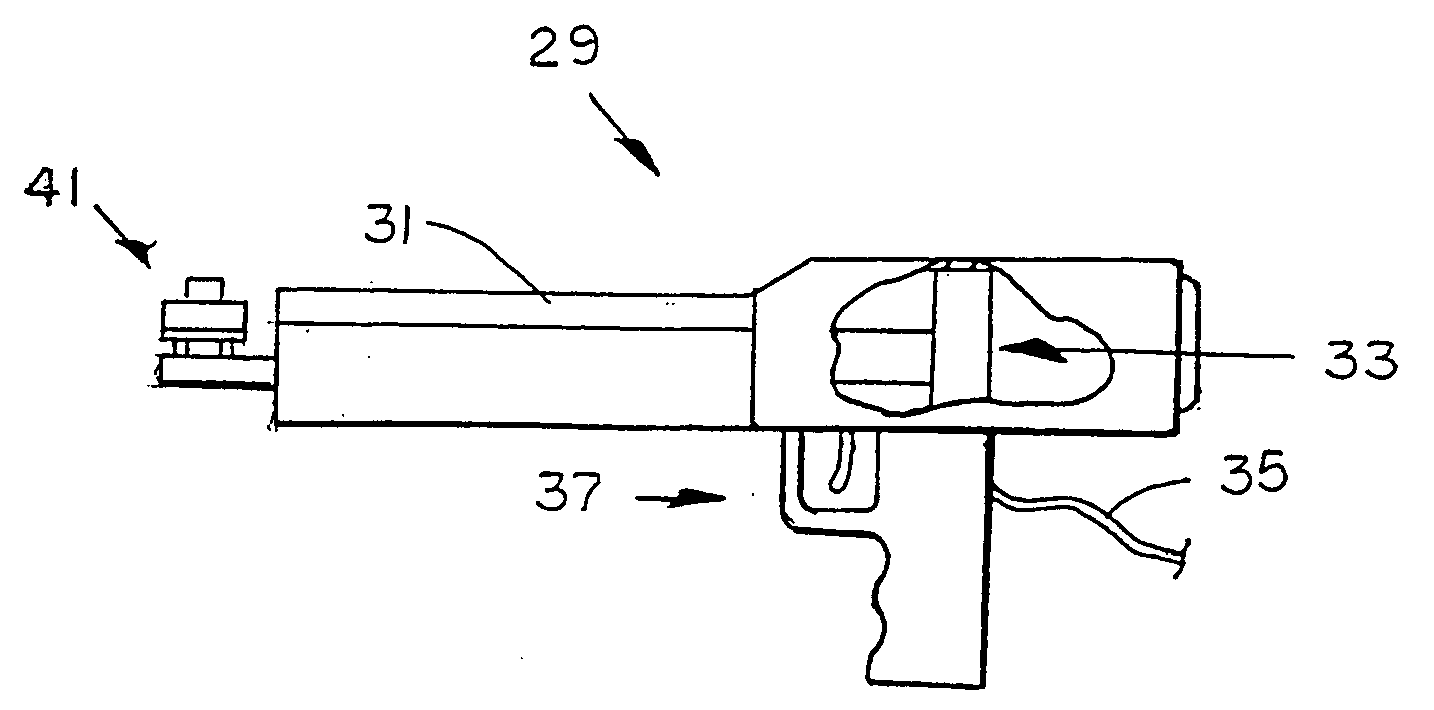

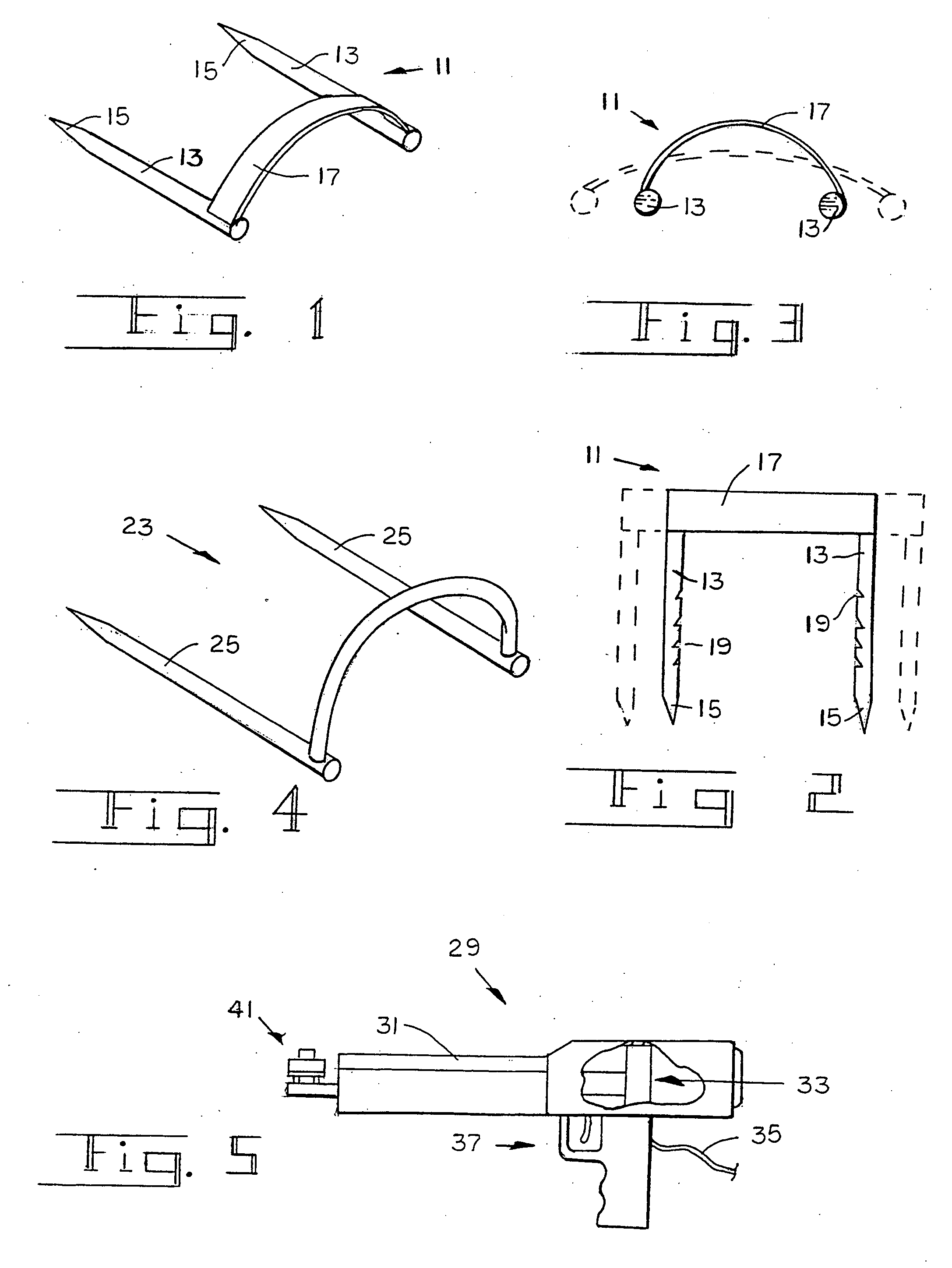

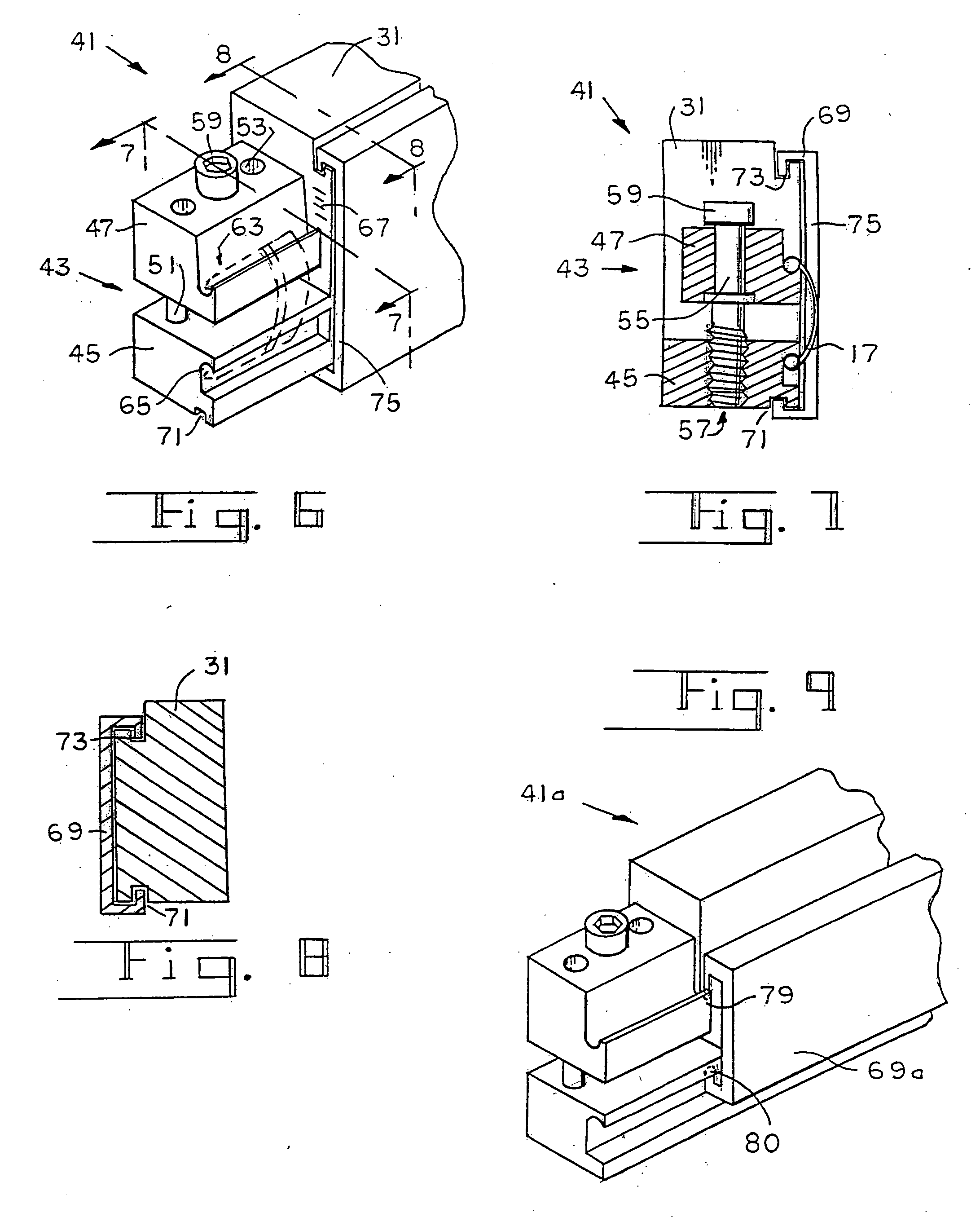

[0057] Referring now the drawings, FIGS. 1-3 show that a preferred embodiment of a compression staple 11 according to the present invention has a pair of legs 13 with sharp front ends 15 and a bridge 17 that interconnects the rear end portions of legs 13. Staple 11 is fabricated of a surgical grade, bio-compatible metal, such as stainless steel, titanium alloy or other suitable alloy. Bridge 17 functions not only to hold legs 13 in approximate parallel relationship, but is selected to act as a spring by the flexing of its bow when the legs are spread apart as illustrated by the broken line image of FIGS. 2 and 3. This imparts an inward reacting force between the legs proportional to the degree of their displacement. It will be appreciated that the dimensions, gauge and curvature of bridge 17 are selected such that it can be flexed to a tensioned state that will deliver the compression requirements of the bone fixation to which staple 11 is to be applied.

[0058] It is preferred that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com